A three-stage blasting and multi-directional soft rock grouting reinforcement method

A grouting reinforcement, multi-directional technology, used in drilling equipment and methods, earth-moving drilling, wellbore/well components, etc. Control and other issues, to achieve the effect of easy control of orientation and angle, good accuracy, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

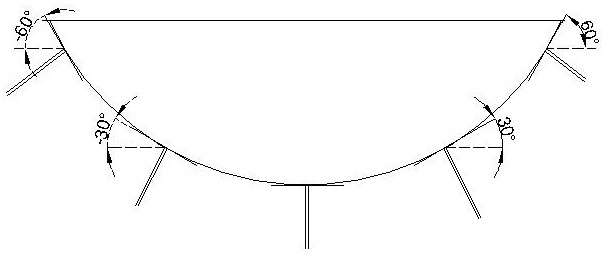

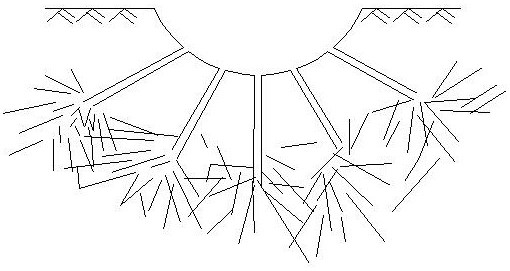

[0027] Such as Figure 1~4 As shown, a three-stage blasting and multi-directional soft rock roadway floor grouting reinforcement method includes the following steps:

[0028] Step 1: The roadway section of a coal mine is rectangular, the roadway width is 5.24m, the height is 3.8m, the floor is soft rock, and micro-cracks are relatively developed. A hemispherical groove with a diameter of 4m is dug on the floor of the roadway.

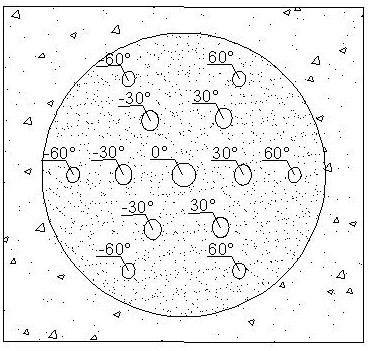

[0029] Step 2: Determine the location of the drilled holes in the hemispherical groove, where the angles between the tangent of the curve on the groove where the drilled hole is located and the horizontal plane are 0°, 30°, 60°, -30°, -60°, along the The counterclockwise direction is positive, 0° drilling is 1, and the number of drilling holes at other angles is 6 and evenly distributed on the hemispherical groove.

[0030] Step 3: Drill holes at the drilling positions determined in step 2, wherein the diameter of the drilled holes is 100mm, and the to...

Embodiment 2

[0038] Such as figure 1 , 5 As shown, a three-stage blasting and multi-directional tunnel side wall grouting reinforcement method includes the following steps:

[0039] Step 1: The section of a tunnel is arched, the tunnel is 8.8m high, the height is 6.4m, the side wall is soft rock, and micro-cracks are relatively developed. A hemispherical groove with a diameter of 3.5m is dug on the side wall of the tunnel.

[0040] Step 2: Determine the location of the drilled holes in the hemispherical groove, where the angles between the tangent of the curve on the groove where the drilled hole is located and the horizontal plane are 0°, 30°, 60°, -30°, -60°, along the The counterclockwise direction is positive, 0° drilling is 1, and the number of drilling holes at other angles is 6 and evenly distributed on the hemispherical groove.

[0041] Step 3: Drill holes at the drilling positions determined in step 2, wherein the diameter of the drilled holes is 90mm, and the total length of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com