Loader working system based on servo electric cylinders

A servo electric cylinder and working system technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of insufficient precision of electric proportional handle control, large vibration of the whole machine, difficult Real-time control and other issues to achieve the effect of precise and controllable working stroke and working speed, low manufacturing cost and convenient vehicle installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

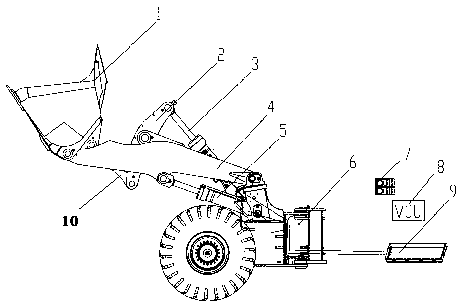

[0024] like figure 1 As shown, a loader working system based on a servo electric cylinder includes a loader body 6, a pair of booms 4 hinged to the loader body 6, and a boom is hinged between the middle of the boom 4 and the loader body 6 Servo electric cylinder 5; through the extension and retraction of the boom servo electric cylinder 5, the lifting and falling of the boom 4 are realized. A bucket 1 is hinged at the other end of a pair of booms 4, and a rocker arm 10 is hinged at the middle of the bucket 1; a rocker tie rod 2 is hinged at the other end of the rocker arm 10; The middle part is hinged on a pair of seat beams, and the bucket servo electric cylinder 3 is hinged between the other end of the rocker arm rod 2 and the loader body 6; Tipping bucket and closing bucket. A battery pack 9 for powering the bucket servo electric cylinder 3 and the boom servo electric cylinder 5 is also installed on the loader body 6 .

Embodiment 2

[0026] On the basis of above-mentioned embodiment one, combine again figure 2 and image 3 Shown:

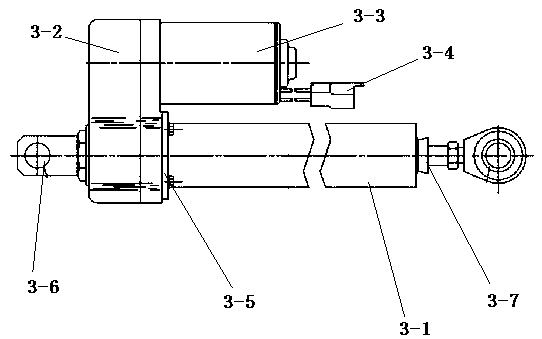

[0027] Boom servo electric cylinder 5 has the same structure as bucket servo electric cylinder 3, taking bucket servo electric cylinder 3 as an example:

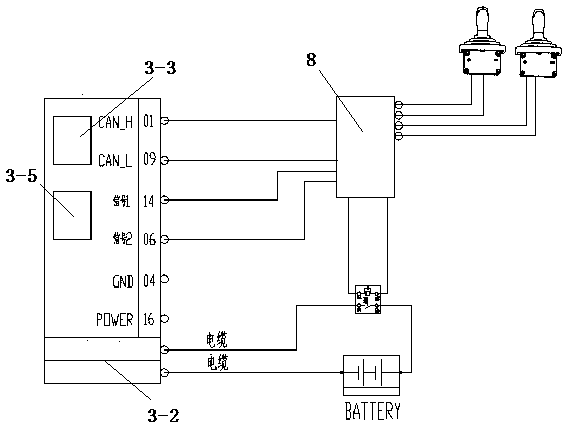

[0028] The bucket servo electric cylinder 3 includes a planetary roller screw 3-1, one side of the planetary roller screw 3-1 is fixedly connected with a servo motor 3-2, and the planetary roller screw 3 is driven by the servo motor 3-2 -1, to realize the linear extension and retraction motion of the lead screw in the planetary roller screw 3-1. The servo motor 3-2 is connected to the battery pack 9 through the cable interface 3-6, and the battery pack 9 supplies power for the servo motor 3-2. The servo motor 3-2 is connected with a controller 3-3, the controller 3-3 is connected with a CAN communication interface 3-4, the CAN communication interface 3-4 is connected with the vehicle controller 8CAN bus interface, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com