Heat absorption layer material for vacuum pipe solar water heater

A technology for solar water heaters and heat-absorbing layers, applied to radiation-absorbing coatings, coatings, anti-corrosion coatings, etc., can solve problems such as loss, achieve strong adhesion, not easy to fall off, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

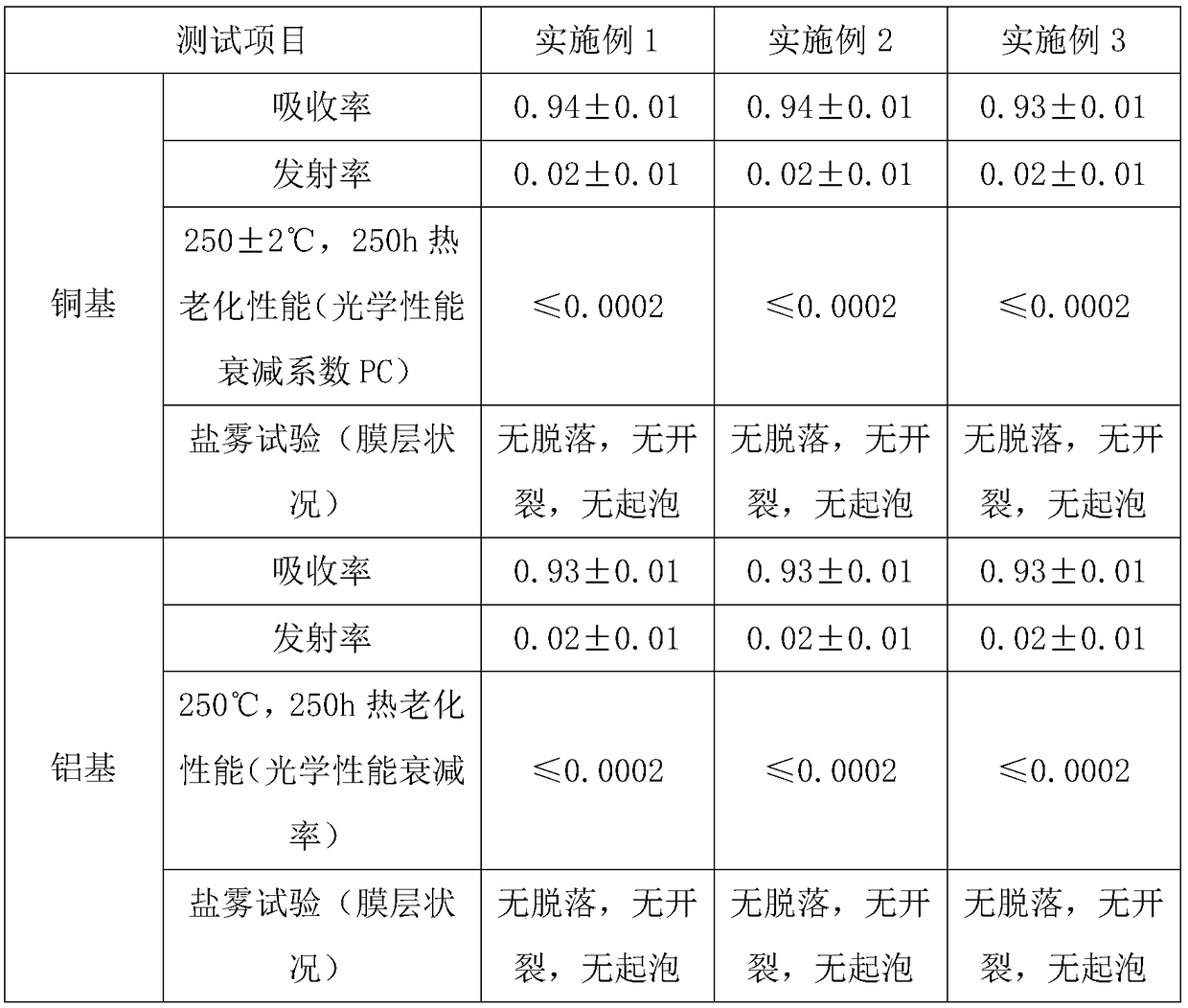

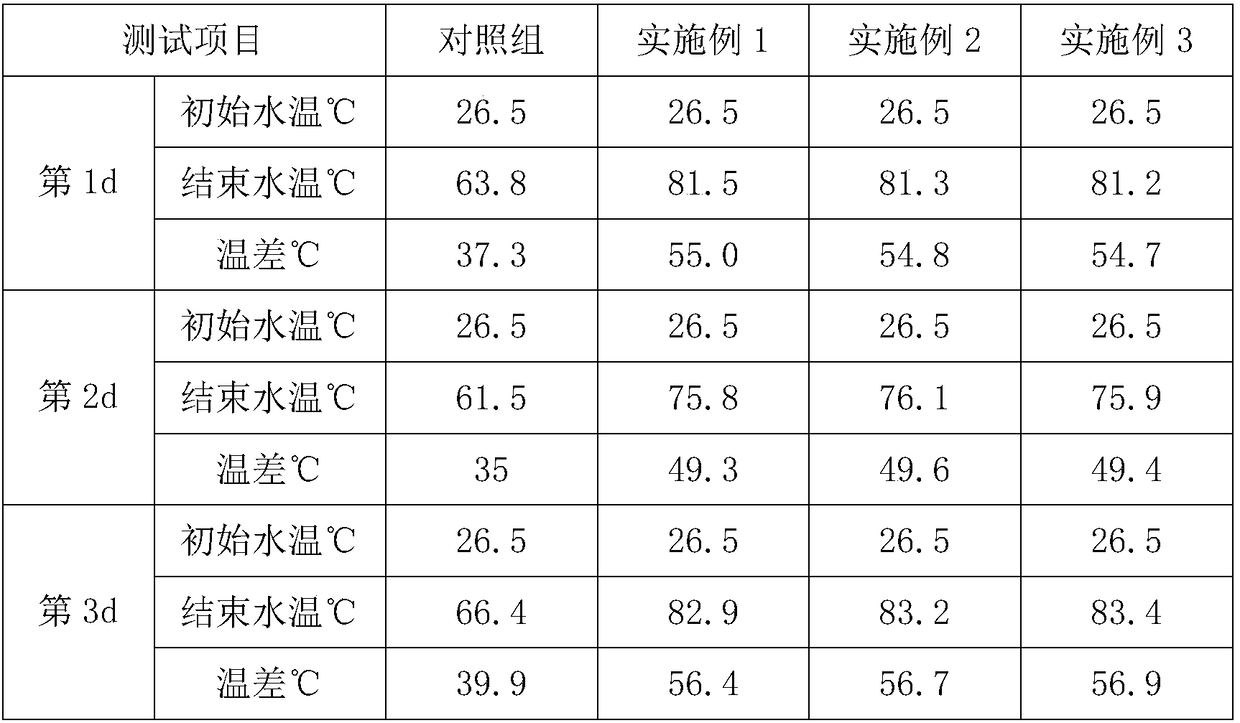

Embodiment 1

[0036] A heat-absorbing layer material for a vacuum tube solar water heater, the heat-absorbing layer material is located on the outer layer of the inner tube of the vacuum tube; the components of the heat-absorbing layer material include: 100 parts of acrylic modified epoxy resin, 90 parts of curing agent , 45 parts of nano-carbon black, 60 parts of chromium nitrate, 1.2 parts of 2,4-dihydroxybenzophenone, 15 parts of radiation energy storage agent, 30 parts of organic solvent, 7 parts of thermal conductivity additive, 1 part of leveling agent, even Joint agent 2.5 parts.

[0037] Wherein, the curing agent is amino-terminated polydimethylsiloxane.

[0038] The organic solvent is a mixture of ethanol and ethyl acetate in a mass ratio of 7:2; the heat conduction additive is a mixture of α-alumina and sodium nitrite in an equal mass ratio.

[0039] The leveling agent is liquid leveling agent SC-333; the coupling agent is KH-792.

[0040] The outer wall of the inner tube of the...

Embodiment 2

[0042] A heat absorbing layer material for a vacuum tube solar water heater, the heat absorbing layer material is located on the outer layer of the inner tube of the vacuum tube; the components of the heat absorbing layer material include: 120 parts of acrylic modified epoxy resin and 100 parts of curing agent in parts by mass , 65 parts of nano carbon black, 80 parts of chromium nitrate, 2.7 parts of 2,4-dihydroxybenzophenone, 25 parts of radiation energy storage agent, 40 parts of organic solvent, 13 parts of thermal conductivity additive, 2 parts of leveling agent, even Joint agent 3 parts.

[0043] Wherein, the curing agent is amino-terminated polydimethylsiloxane.

[0044] The organic solvent is a mixture of ethanol and ethyl acetate in a mass ratio of 7:2; the heat conduction additive is a mixture of α-alumina and sodium nitrite in an equal mass ratio.

[0045] The leveling agent is solid leveling agent RB503; the coupling agent is SCA-602.

[0046] The outer wall of t...

Embodiment 3

[0048] A heat absorbing layer material for a vacuum tube solar water heater, the heat absorbing layer material is located on the outer layer of the inner tube of the vacuum tube; the components of the heat absorbing layer material include: 108 parts of acrylic modified epoxy resin, 97 parts of curing agent , 54 parts of nano carbon black, 72 parts of chromium nitrate, 1.9 parts of 2,4-dihydroxybenzophenone, 21 parts of radiation energy storage agent, 36 parts of organic solvent, 11 parts of thermal conductivity additive, 1.5 parts of leveling agent, even Joint agent 2.8 parts.

[0049] Wherein, the curing agent is amino-terminated polydimethylsiloxane.

[0050] The organic solvent is a mixture of ethanol and ethyl acetate in a mass ratio of 7:2; the heat conduction additive is a mixture of α-alumina and sodium nitrite in an equal mass ratio.

[0051] The leveling agent is liquid leveling agent SC-333; the coupling agent is KH-560.

[0052] The outer wall of the inner tube of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com