Packaging paper sterilization device for filling machine

A technology of sterilization device and wrapping paper, which is applied in the direction of packaging material feeding device, packaging sterilization, packaging, etc., can solve the problem of lack of effective sterilization of wrapping paper, and achieve the effect of ensuring the effect of sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

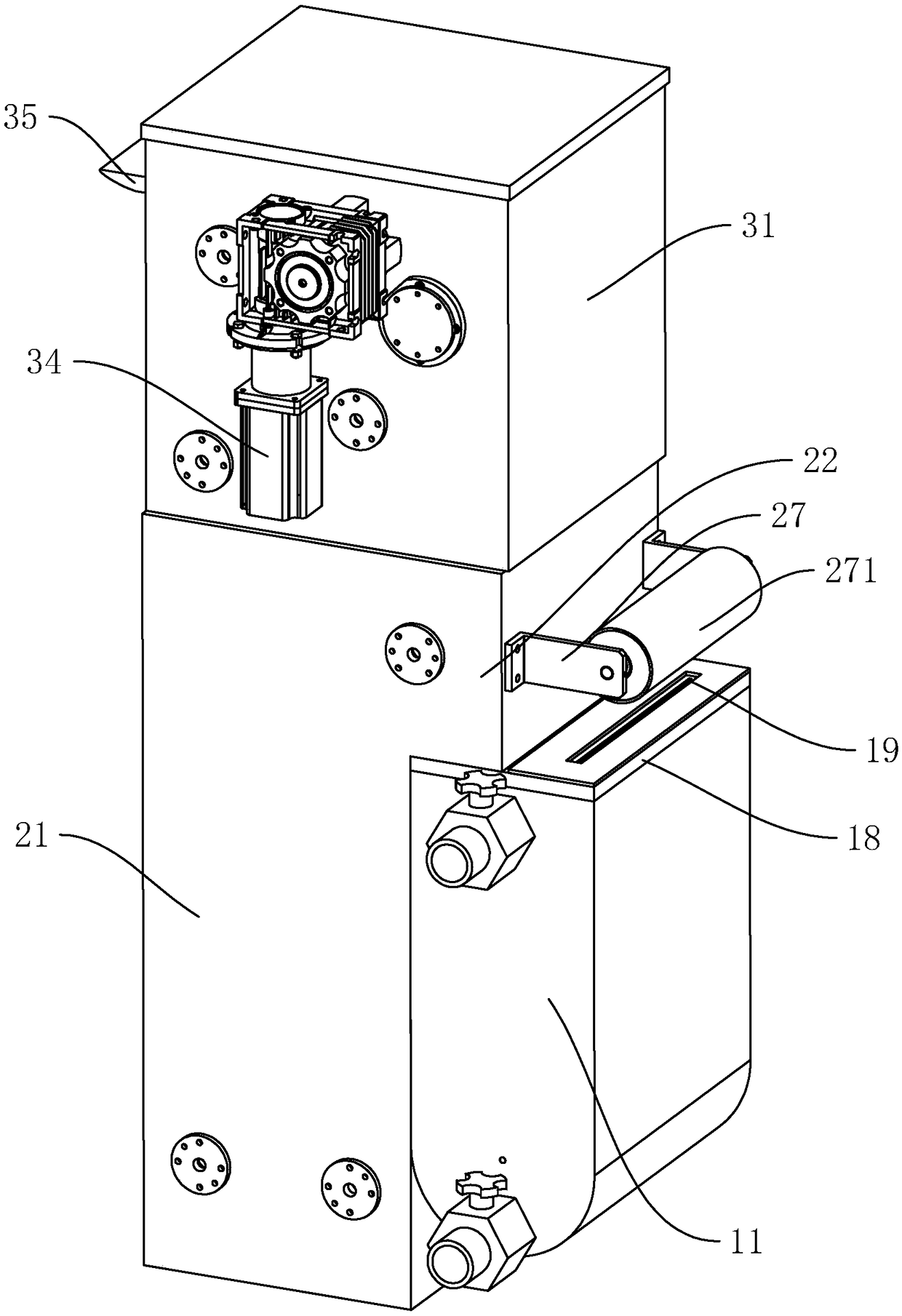

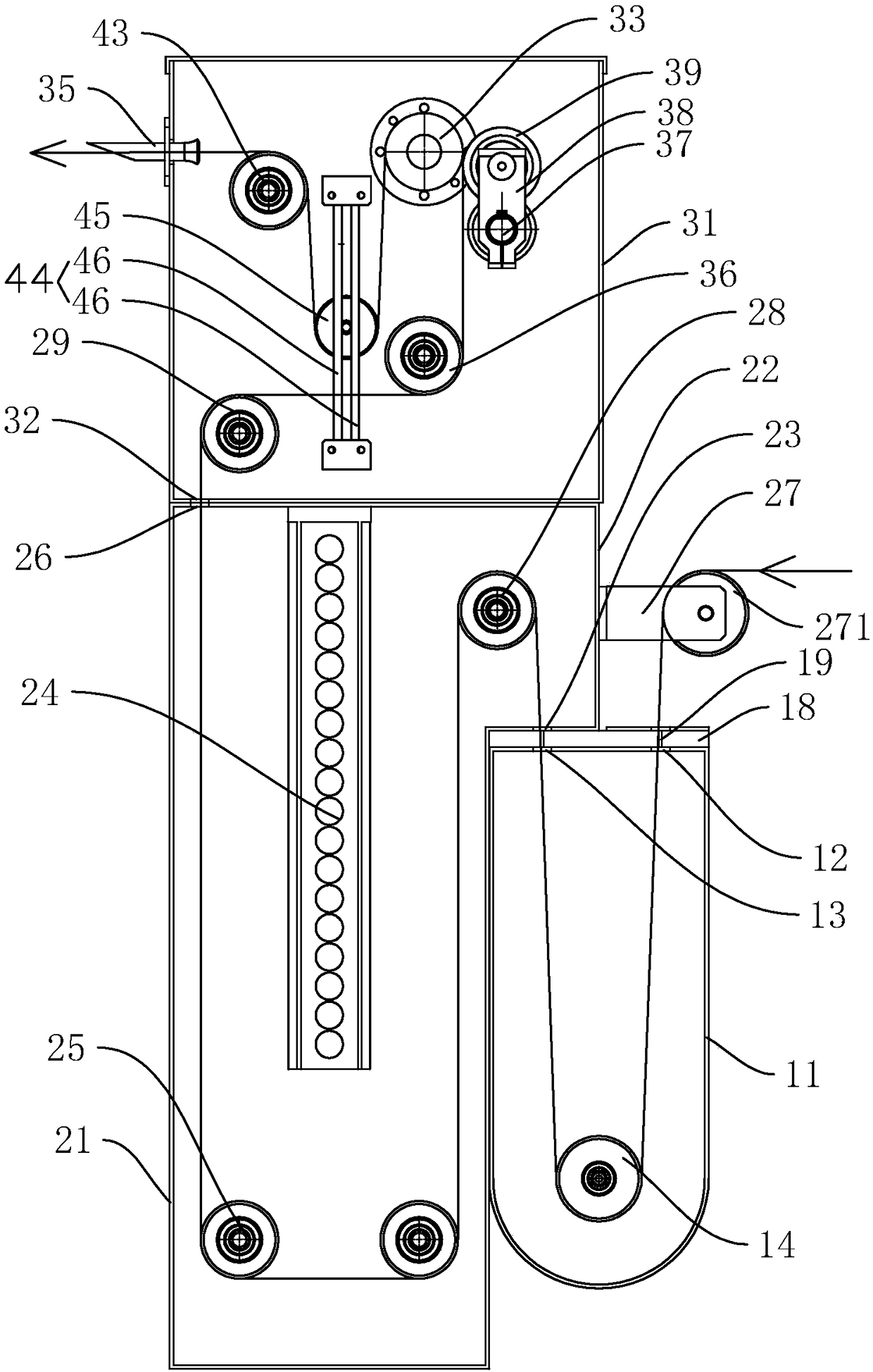

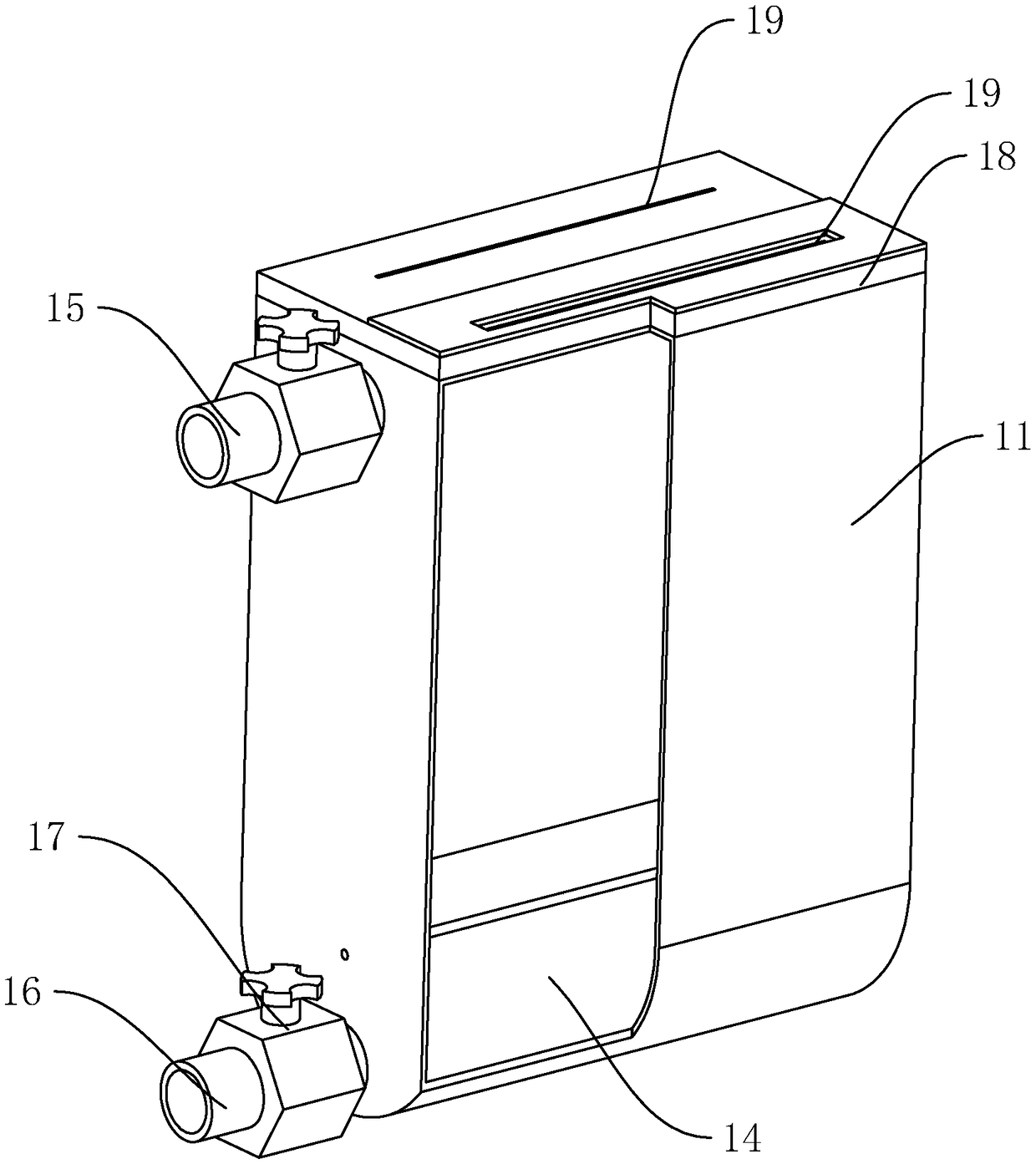

[0032] Wrapping paper sterilization unit for filling machines, such as figure 1 , figure 2 , image 3 Shown, comprise hydrogen peroxide sterilizing box 11, ultraviolet ray sterilizing box 21 and aseptic traction box 31, the upper end face of hydrogen peroxide sterilizing box 11 is provided with the first paper feed slot 12 and the first paper outlet chute 13, hydrogen peroxide sterilizing box 11 Inject hydrogen peroxide into the inner cavity, and the inner cavity of the hydrogen peroxide sterilizing box 11 is rotated and connected with a submerged guide roller 14 below the hydrogen peroxide liquid level; the wrapping paper enters the hydrogen peroxide sterilizing box 11 from the first paper feeding slot 12, and continues to move downwards and enters the hydrogen peroxide. After a certain distance below the liquid surface, after bypassing the submerged guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com