Four-axis rotary carrying platform

A technology of a loading platform and a rotating mechanism, which is applied in the field of loading platforms, can solve problems such as the rigid structure of the loading platform, increase the labor intensity of the staff, and make it inconvenient to adjust the horizontal and vertical movements of the loading platform, so as to achieve multi-directional movement, The effect of reducing labor intensity and ensuring flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

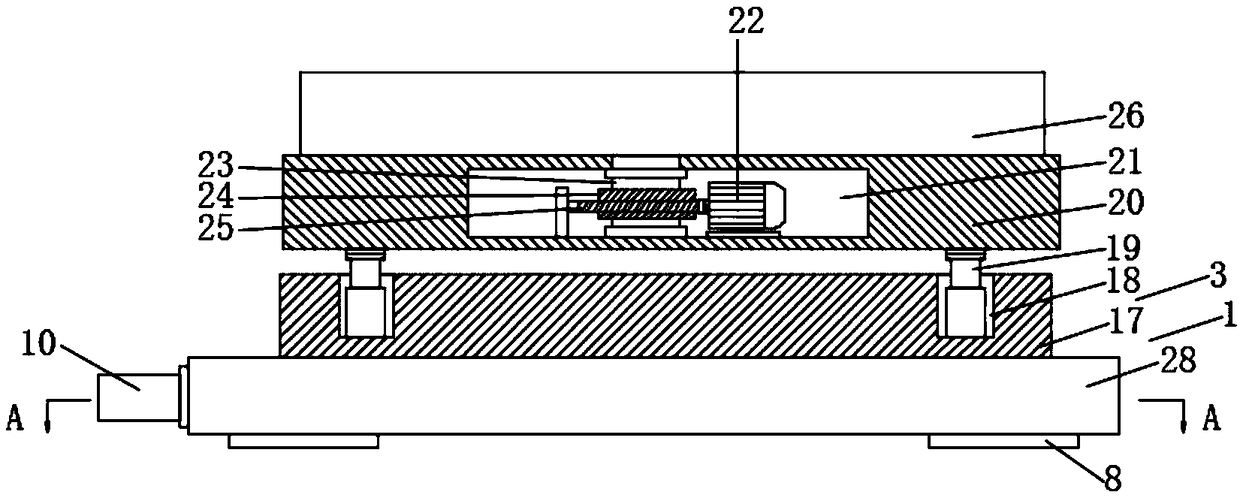

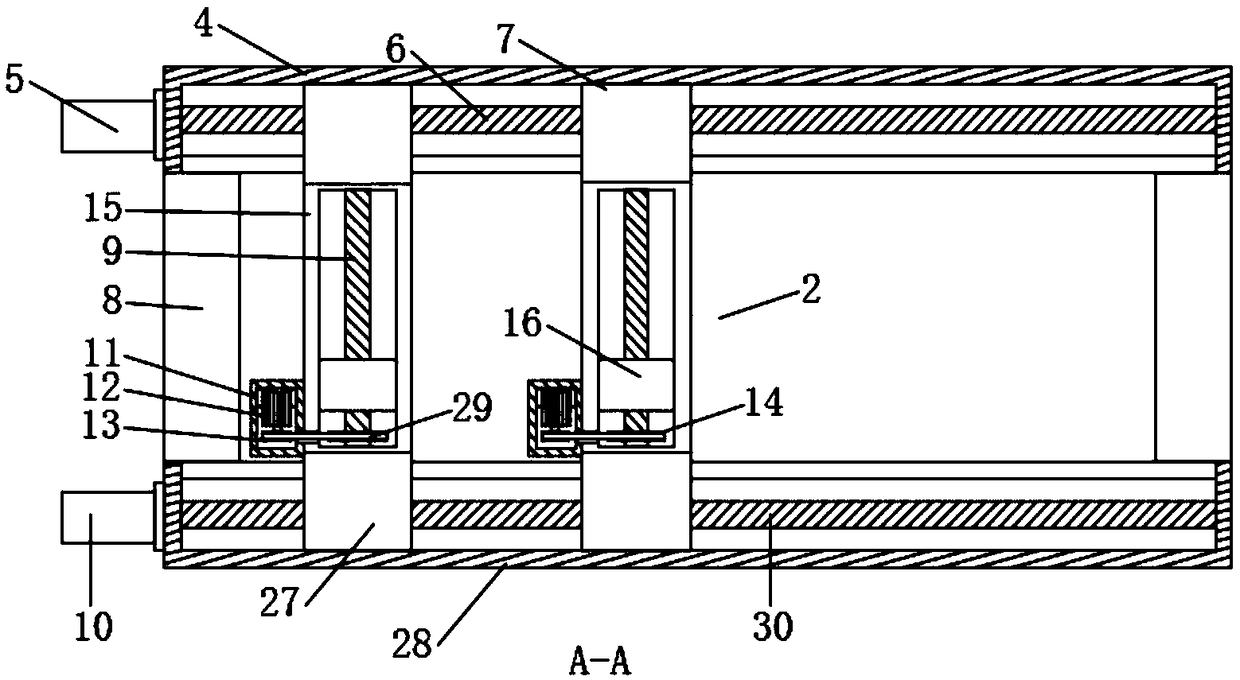

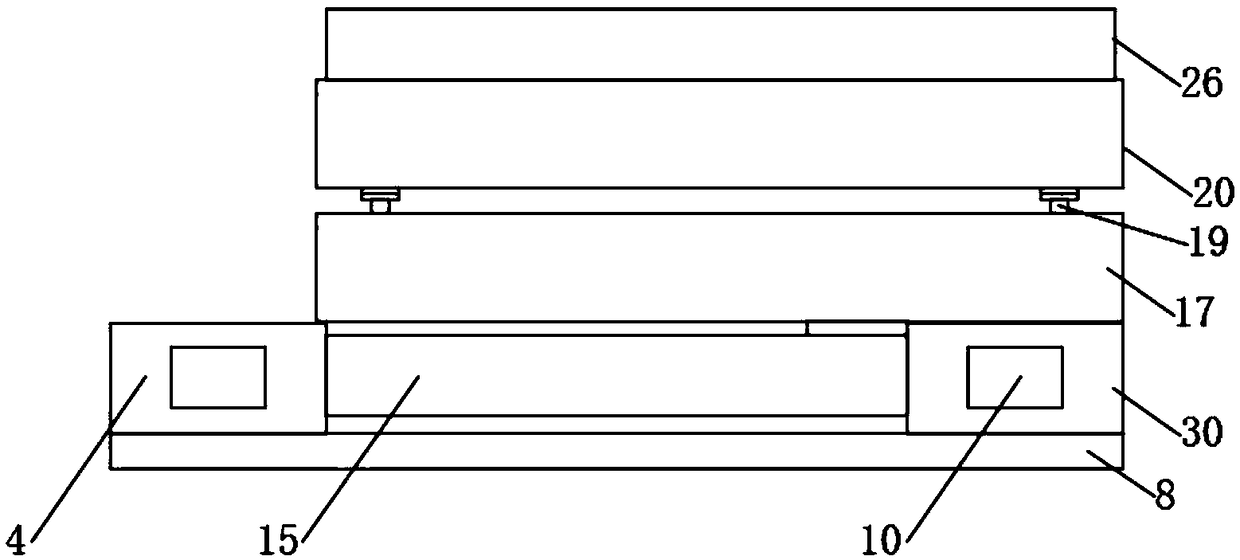

[0020] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a four-axis rotating loading platform, including a lateral movement mechanism 1, a longitudinal movement mechanism 2 and a rotation mechanism 3, and a longitudinal movement mechanism 2 is arranged above the transverse movement mechanism 1 , the top of the longitudinal moving mechanism 2 is provided with a rotating mechanism 3, and the horizontal moving mechanism 1 is composed of a first moving chute 4, a first moving motor 5, a first screw mandrel 6, a first slider 7, and a connecting beam 8 , the second slider 27, the second moving chute 28 and the third screw rod 30, one end of the connecting beam 8 is fixedly connected with the first moving chute 4, and the inner wall of the first moving chute 4 has symmetrical ends The first screw rod 6 is rotatably connected between them, and the inner wall of the first moving chute 4 is slidably connected with two first sliders 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com