Preparation method of soybean dietary fiber

A technology of soybean dietary fiber and soybean, applied in the field of food processing, can solve the problems of high cost, low safety, complicated process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 A kind of preparation method of soybean dietary fiber

[0026] Select soybeans with full particles, no impurities, and no mildew as raw materials, and wash the dust attached to the surface of soybeans with clean water; add 500mL water (beans:water=1:5) to 100g soybeans, and soak for 12 hours in spring, autumn and winter ~16h, and in summer, the water temperature will change due to room temperature, so it only needs to be soaked for 8h; after the water is drained, add 900mL of distilled water at 80°C to the soaked soybeans, and fully refine the pulp in a cooking machine for 3min; use 120- Filter with a 160-mesh filter cloth to separate the pulp and dregs. Try to keep the same force every time you squeeze the bean dregs until there is almost no soy milk; weigh 80g of the processed fresh bean dregs, and sterilize at 115°C for 20 minutes, and the sterilization is complete After that, place it in an ultra-clean bench to cool to room temperature;

[0027] Activa...

Embodiment 2

[0031] Embodiment 2 A kind of preparation method of soybean dietary fiber

[0032] Select soybeans with full grains, no impurities, and no mildew as raw materials, and wash the dust attached to the surface of soybeans with clean water; add 1050mL water (bean:water=1:7) to 150g soybeans, and soak for 12 hours in spring, autumn and winter ~16h, and in summer, the water temperature will change due to room temperature, so it only needs to be soaked for 8h; after the water is drained, add 700mL of distilled water at 75°C to the soaked soybeans, and fully refine the pulp in a cooking machine for 2min; use 120- Filter with a 160-mesh filter cloth to separate the pulp and dregs. Try to keep the same force every time you squeeze the bean dregs until there is almost no soy milk; weigh 100g of the processed fresh bean dregs, and sterilize it at 121°C for 15 minutes. After the end, place it in an ultra-clean bench to cool down to room temperature;

[0033] Activation of Kluyveromyces mar...

Embodiment 3

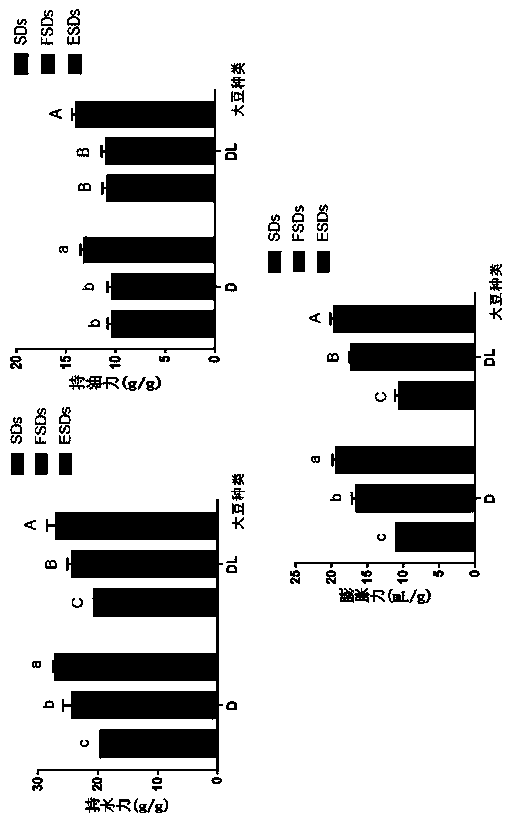

[0037] Example 3 Sample preparation of different treatment methods

[0038] The raw materials of the samples are Heihe No. 43 soybeans or Suiwuxing No. 2 soybeans.

[0039] 1. Preparation of soybean dietary fiber

[0040] The preparation method is the same as in Example 1, the okara-insoluble dietary fiber of Heihe No. 43 soybeans is named ESDs-L; the okara-insoluble dietary fiber of Suiwuxing soybean No. 2 is ESDs-DL;

[0041] 2. Preparation of fermented bean dregs

[0042] The preparation method of Heihe No. 43 soybean and Suiwuxing soybean No. 2 is the same, as follows:

[0043] Select soybeans with full particles, no impurities, and no mildew as raw materials, and wash the dust attached to the surface of soybeans with clean water; add 500mL water (beans:water=1:5) to 100g soybeans, and soak for 12 hours in spring, autumn and winter ~16h, and in summer, the water temperature will change due to room temperature, so it only needs to be soaked for 8h; after the water is dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com