A mutton sheep fattening ftmr based on micro-storage rice straw and its preparation method

A technology of straw and mutton sheep, which is applied in FTMR and preparation of mutton sheep fattening and intensive house-feeding of mutton sheep. It can solve the problems of not being able to adapt to large-scale and intensive production, the cost of purchasing machinery and equipment cannot be afforded, and disrupting the dynamic balance of digestion and metabolism, etc. problems, to achieve the effects of reducing the use of pharmaceutical additives, avoiding rumen dysfunction, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

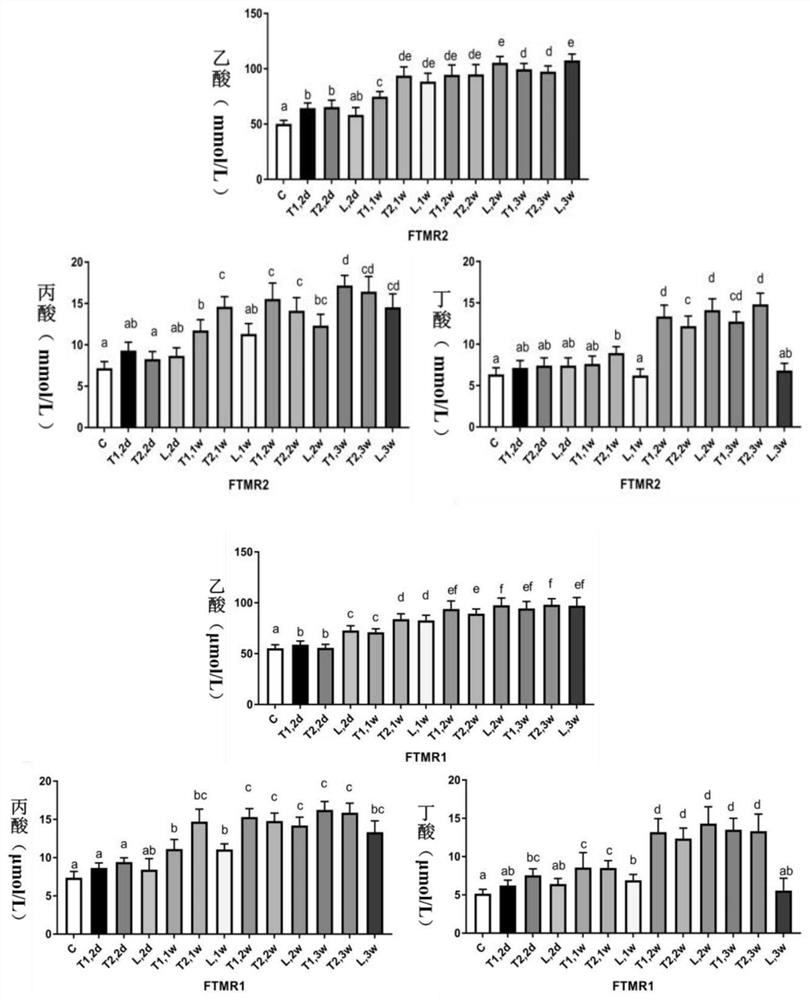

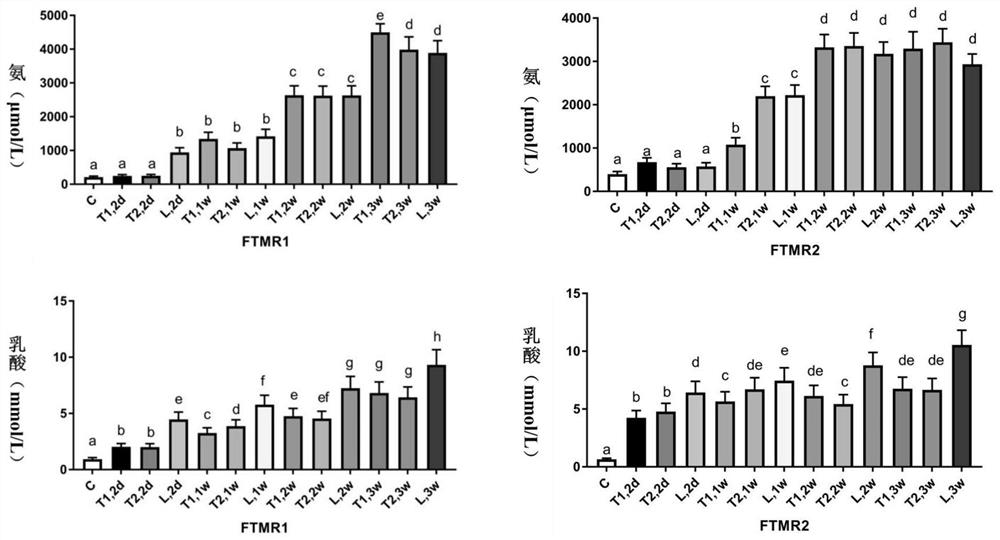

Image

Examples

Embodiment Construction

[0043] (1) Raw material preparation

[0044] Micro-storage rice straw: In the Jiangnan agricultural area, the rice is harvested and threshed when 1 / 3 of the leaves of the plant are green leaves at the mature stage. In comparison, softness, good palatability, digestibility, and nutritional value have all been significantly improved, and can be stored for a long time. According to measurements, the micro-storage rice straw has a dry matter content of 45%-55%, crude protein 4%-7%, crude fiber 30%-40%, crude fat 1%-2%, and ash content <15%. The output of rice straw in Jiangnan agricultural area is large, and micro-storage rice straw has been widely used as an effective method of straw feed, so the supply is sufficient.

[0045] Palm meal: It is a by-product of palm kernel shelling and oil extraction. Its shape and color are similar to rapeseed meal, and it has a slightly chocolate smell. High in protein and crude fat, it can be used as both protein feed and energy feed for rumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com