Method for manufacturing inorganic fireproof medium-high voltage cable

A technology of medium and high voltage cables and manufacturing methods, which is applied in the manufacture of cables/conductors, for reducing the size of conductors/cables, insulating cables, etc., and can solve the problems of multiple cable laying, energy consumption, consumables, etc., and improve structural stability Performance and impact resistance, reducing stress and mechanical damage, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

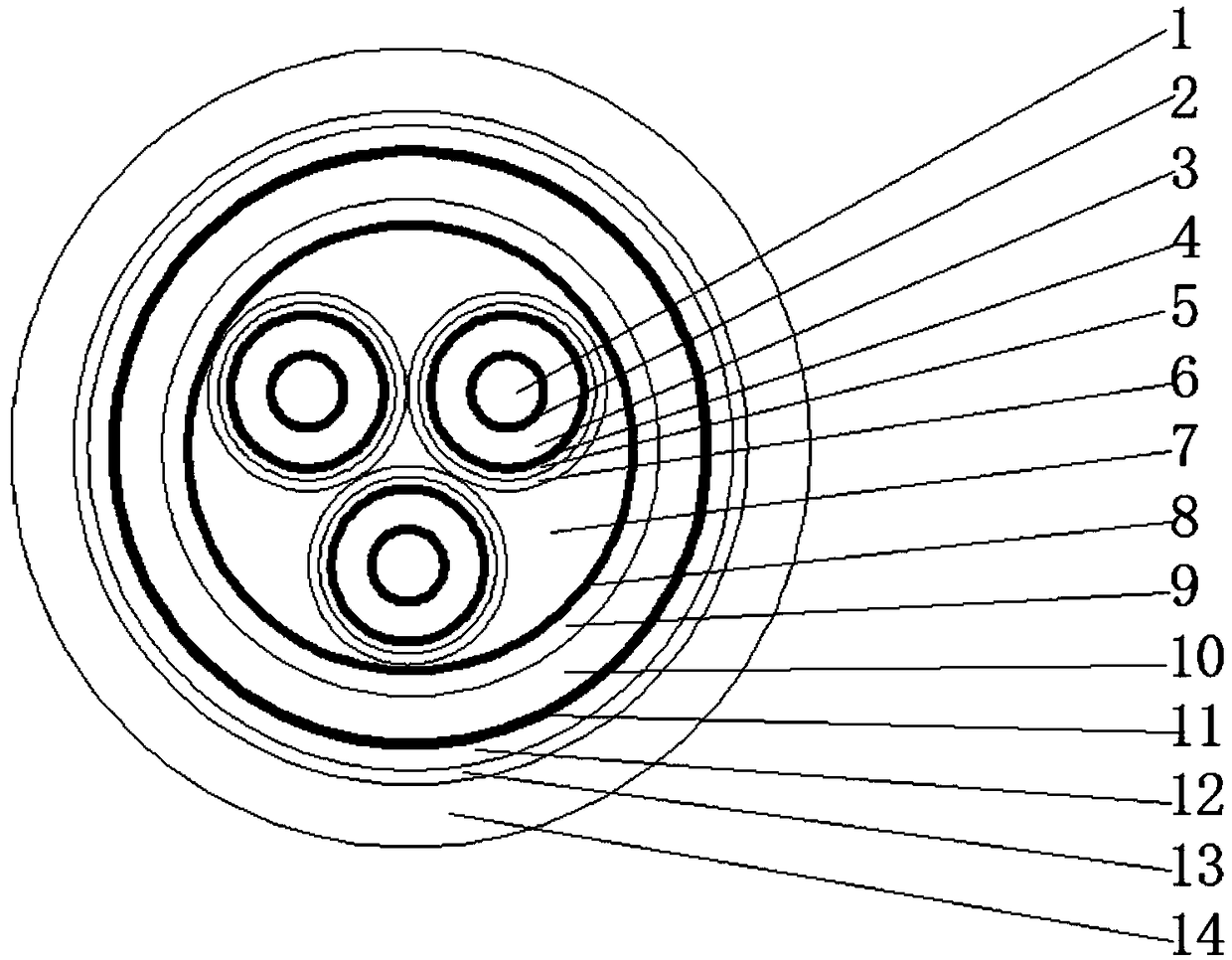

[0033]A method for manufacturing an inorganic fireproof medium and high voltage cable, the method comprising the following steps: A, wire drawing; B, conductor stranding; C, three-layer co-extrusion chemical crosslinking; D, wrapping buffer layer 5; Phase metal shielding layer 6; F, cabling; G, extruded oxygen barrier layer 9; H, inorganic fireproof layer 10 wrapped; I, metal armor; J, wrapped; K, extruded outer sheath 14; L , performance testing;

[0034] The wire-drawing step refers to the use of high-conductivity copper rods for electrical use on the wire-drawing annealing equipment to draw electrical round copper wires with different wire diameters through multiple molds;

[0035] The conductor stranding step refers to that the electrical round copper wire formed after the wire drawing process is twisted and compacted into a circular conductor 1 according to a stranding pitch that is 12 times the diameter of the stranding conductor;

[0036] The three-layer co-extrusion c...

Embodiment 2

[0047] A method for manufacturing an inorganic fireproof medium and high voltage cable, the method comprising the following steps: A, wire drawing; B, conductor stranding; C, three-layer co-extrusion chemical crosslinking; D, wrapping buffer layer 5; Phase metal shielding layer 6; F, cabling; G, extruded oxygen barrier layer 9; H, inorganic fireproof layer 10 wrapped; I, metal armor; J, wrapped; K, extruded outer sheath 14; L , performance testing;

[0048] The wire-drawing step refers to the use of high-conductivity copper rods for electrical use on the wire-drawing annealing equipment to draw electrical round copper wires with different wire diameters through multiple molds;

[0049] The conductor stranding step refers to that the electrical round copper wire formed after the wire drawing process is twisted and compacted into a circular conductor 1 according to a stranding pitch that is 12 times the diameter of the stranding conductor;

[0050] The three-layer co-extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com