Liquid crystal display structure

A liquid crystal display, one-to-one corresponding technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of in-cell polarizer manufacturing difficulties, commercialization difficulties, non-mixing, etc., to save power consumption and reduce light energy. , the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

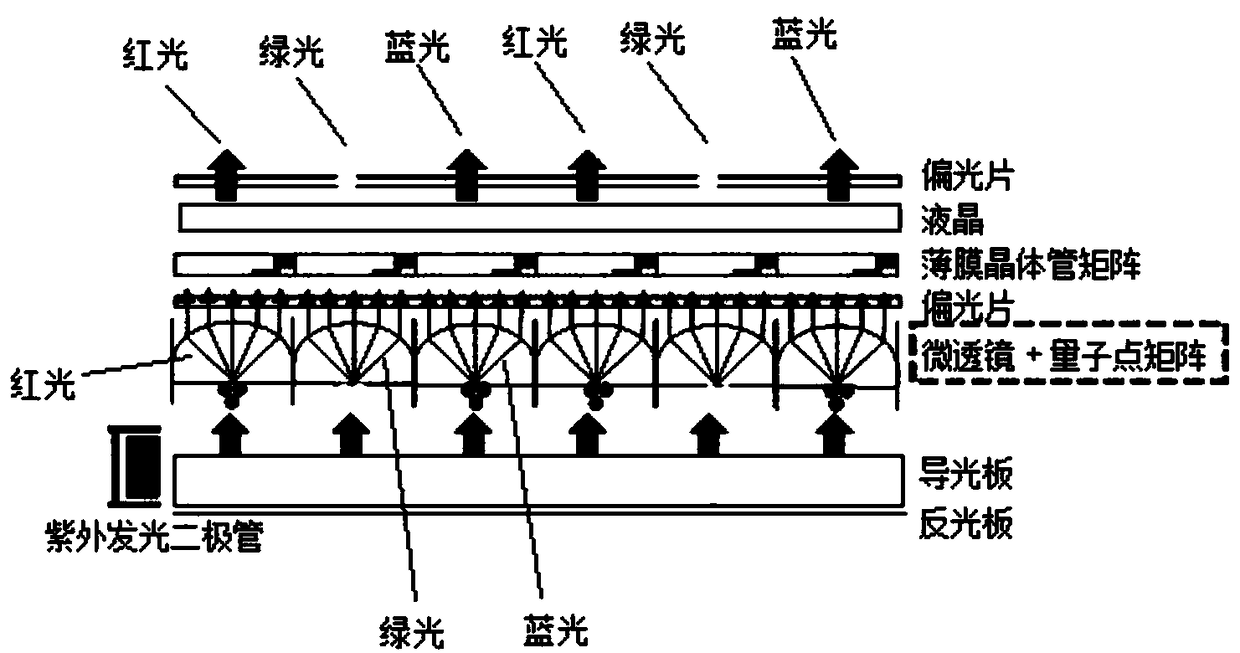

[0019] Such as figure 1 As shown, a liquid crystal display structure includes a backlight module block (including sequentially laminated reflectors and light guide plates), a lower polarizer, a thin film transistor matrix, liquid crystal, an upper polarizer, and also includes an ultraviolet light source, a quantum dot matrix layer and The microlens array layer, the ultraviolet light source is located on the side of the backlight module, the backlight module, the quantum dot matrix layer, the microlens array layer, the lower polarizer, the thin film transistor matrix, the liquid crystal and the upper polarizer are stacked in sequence, and the The microlens has corresponding quantum dots in the direction perpendicular to the lamination. The size of the quantum dots should meet the conditions for forming RGB colors. The refraction part of the microlens makes the refracted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com