Method for testing conductivity correction coefficients of 7-series aluminum alloys with different curvature radii

A technology of curvature radius and correction coefficient, which is used in the field of testing the conductivity correction coefficient of different curvature radii.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

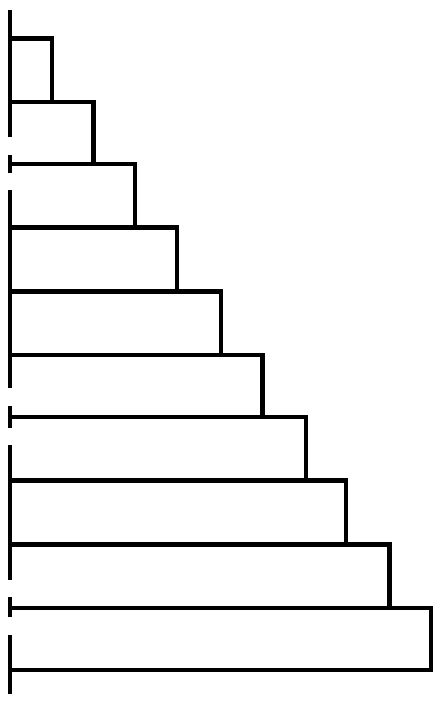

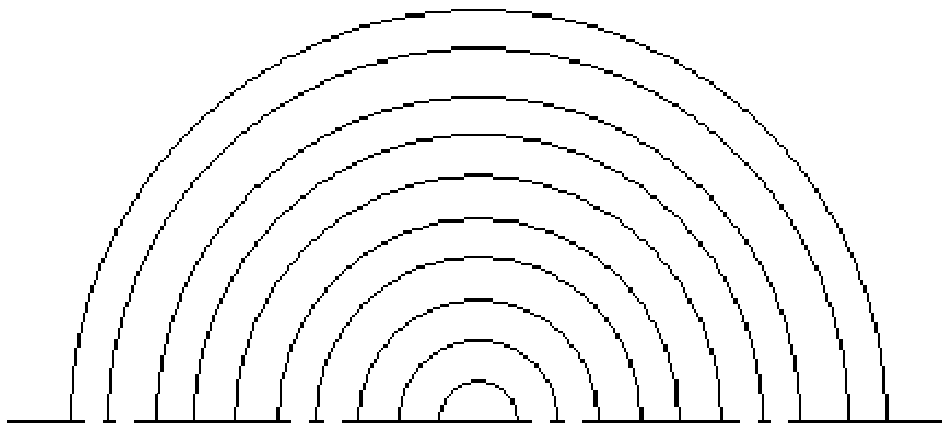

[0020] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment in detail. This embodiment is a test method for the correction coefficient of conductivity of different radii of curvature of 7 series aluminum alloys, which is completed according to the following steps:

[0021] 1. Selection of sample material:

[0022] Select a 7-series aluminum alloy round ingot, and obtain a round bar after equalizing, surface turning, heating, extrusion, quenching and sawing;

[0023] 2. Production of samples with different curvature radii:

[0024] Machining the circular rods prepared in step 1, forming circular steps with different diameters on the circular rods, and the diameters increase sequentially from top to bottom, and then processing one on each of the curved surfaces of circular steps with different diameters plane, and the length of the processing plane is greater than or equal to 20mm, the width of the processing plane is the same as the heigh...

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the diameter of the round rod described in step 1 is 160 mm, and the length is 200 mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the length of the processing plane in step 2 is 20 mm, and the width of the processing plane is 20 mm. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com