A Quantitative Measurement System and Method for Refractive Index Field Based on Phase Calibration

A quantitative measurement and refractive index technology, which is applied in the phase influence characteristic measurement, measurement device, instrument, etc., can solve the problems of large influence on the result, insufficient contrast, and little quantitative analysis, etc., and achieve the effect of quantitative measurement and reduction of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

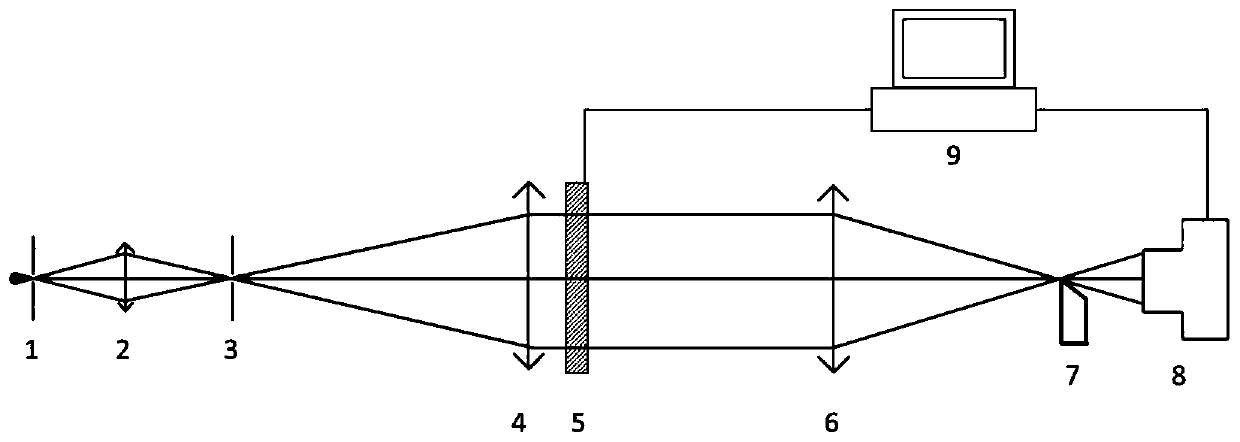

[0046] This embodiment provides a quantitative measurement system for the refractive index field based on phase calibration, such as figure 1 As shown, it includes a light source 1 and a focus lens 2, an aperture diaphragm 3, a collimator lens 4, a detection area 5, an imaging lens 6, a knife edge 7, and a detector 8 arranged sequentially behind the light source 1, and the detection area 5 is used for calibration. It is used to place the standard phase control element. During the measurement, the standard phase control element is replaced by the field to be measured and placed in the detection area 5; the light emitted by the light source 1 is converged at the pinhole diaphragm 3 through the focusing lens 2, and then passed through the collimating lens 4 becomes parallel light, and after passing through the detection area 5, the light emitted by the imaging lens 6 is cut by the knife edge 7 and then imaged on the detection surface of the detector 8; it also includes a control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com