Automatic feeding system used for tungsten carbide powder

A feeding system, tungsten carbide powder technology, applied in furnaces, lighting and heating equipment, furnace components, etc., can solve problems such as poor fluidity, affecting feeding efficiency, increasing production costs, etc., to avoid internal blockage or idling, Reduce cleaning and maintenance frequency and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

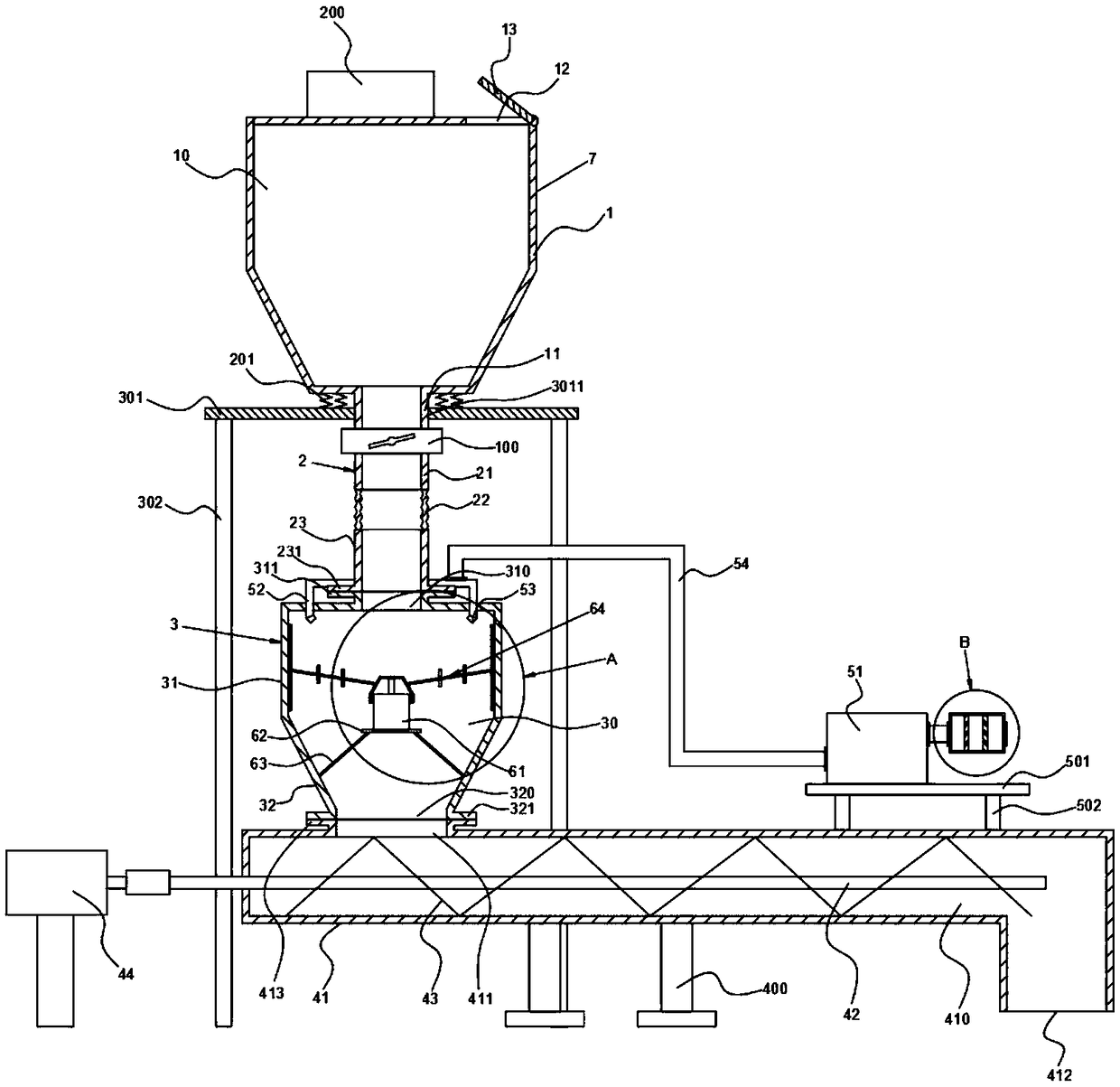

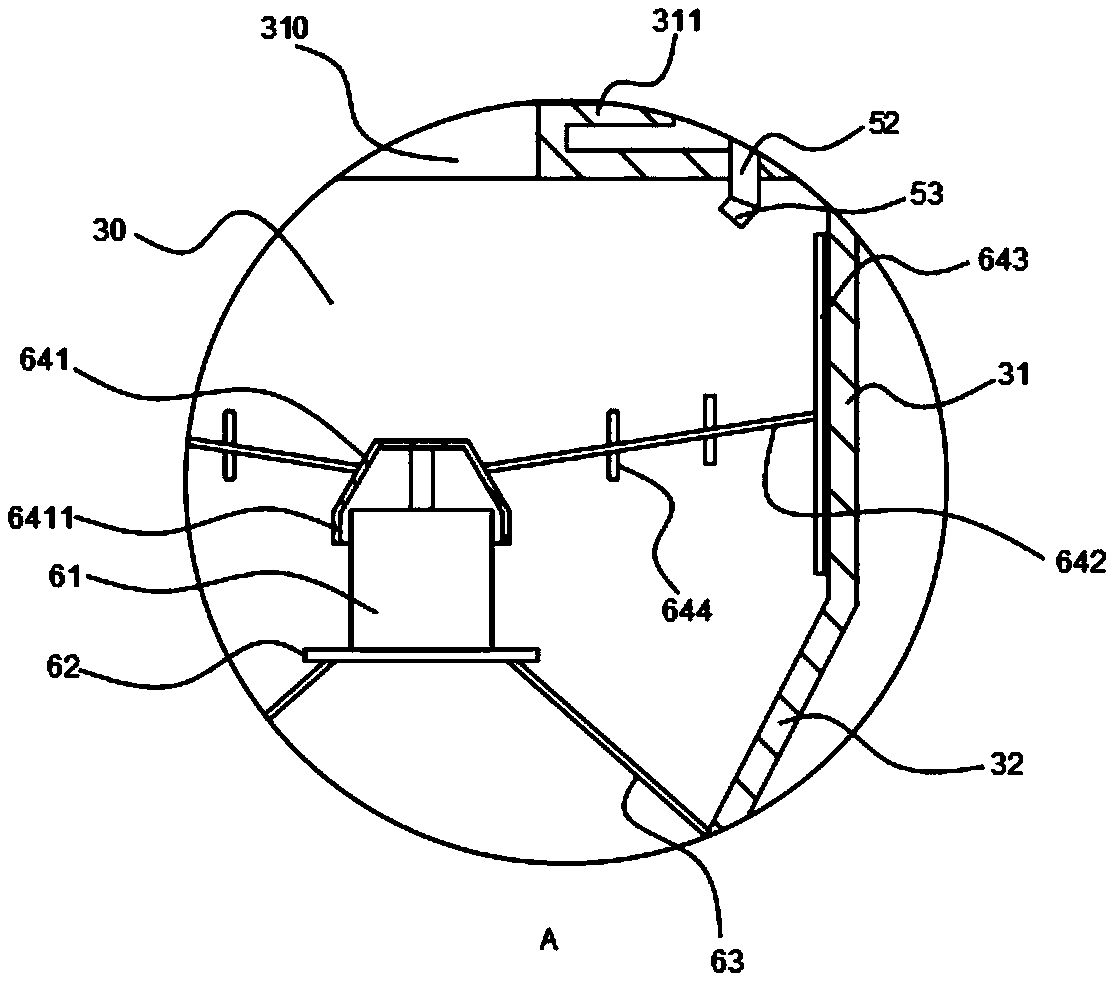

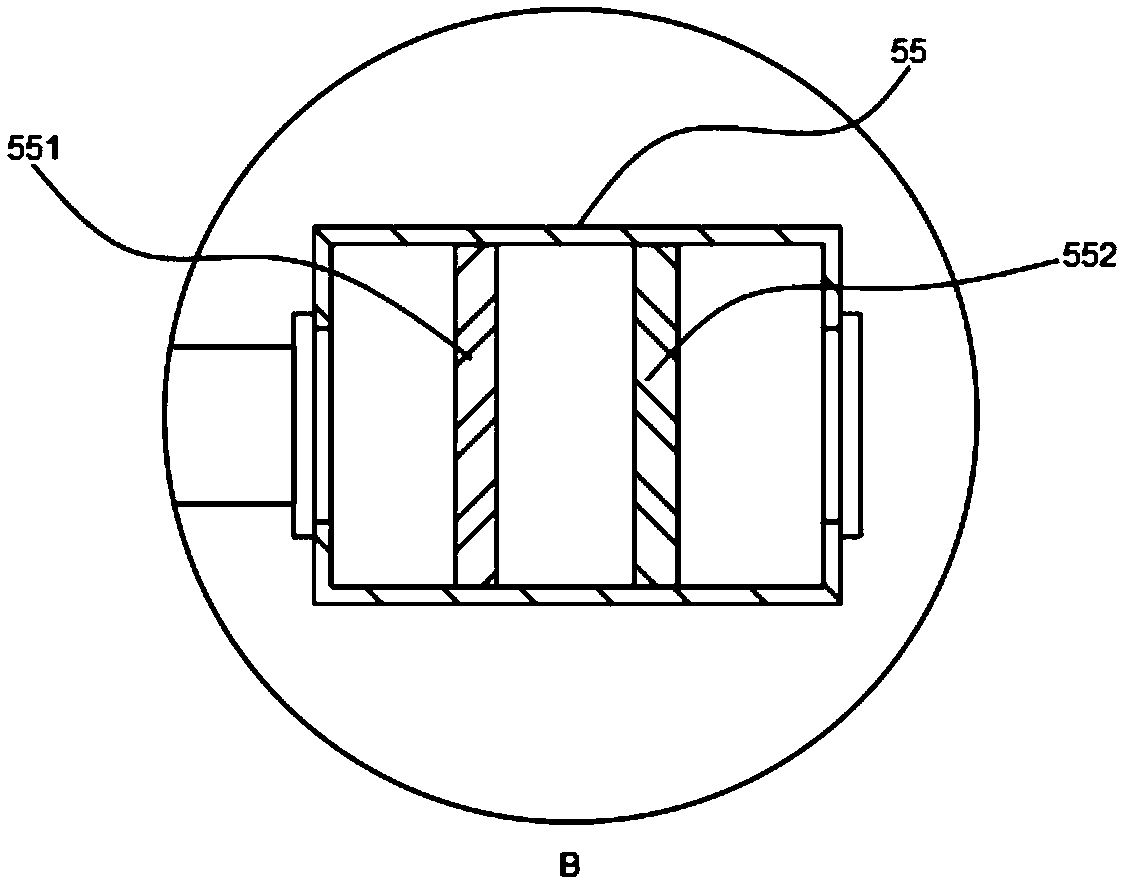

[0022] Such as Figure 1 to Figure 3 As shown, an automatic feeding system for tungsten carbide powder includes a first material barrel 7, a screw conveyor, a second material barrel 3 fixed on the screw conveyor and connected to the screw conveyor, a feeding pipe 2, fixed on the The agitator and purger in the second material barrel 3, the first material barrel 7 is fixed above the second material barrel 3 and connected to the second material barrel 3 through the feed pipe 2. A sealed first chamber 10 is provided, and a sealed second chamber 30 is provided in the second material barrel 3; specifically, the first material barrel 7 is provided on the first barrel body by the first barrel body 1 and the sealing cover 1 Cover plate 13 at the top, the bottom of the first barrel 1 is provided with a first discharge pipe 11 communicating with the first chamber 10, one end of the first discharge pipe 11 is connected to one end of the delivery pipe 2 through a butterfly valve 100 condu...

Embodiment 2

[0034] Such as Figure 4 As shown, at the end of the second discharge port 412 of the material delivery cylinder 41, another delivery pipe is connected to a second material barrel 3 with an agitator and a purging device and a screw conveyor, so that tungsten carbide can be formed. The secondary conveying of the powder, so as to further break the cohesiveness between the tungsten carbide powders, and improve the feeding efficiency; the conveying pipe can also be the conveying pipe 2, so that the screw conveyor in the first stage of conveying needs to be fixed on the On the table, this facilitates the installation and fixation of the screw conveyor in the secondary conveying stage. Of course, the present invention is not limited to secondary conveying, and can also be multi-stage conveying above secondary stage, which can be selected according to the needs of users.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com