Dry vacuum pump work system, dirt suction work system and material suction work system

A dry vacuum pump and working system technology, applied in the direction of rotary piston pumps, rotary piston/swing piston pump components, pumps, etc., can solve user health and environmental hazards, large air extraction system, and sewage suction pumps To protect the environment, prolong the maintenance cycle and avoid fuel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

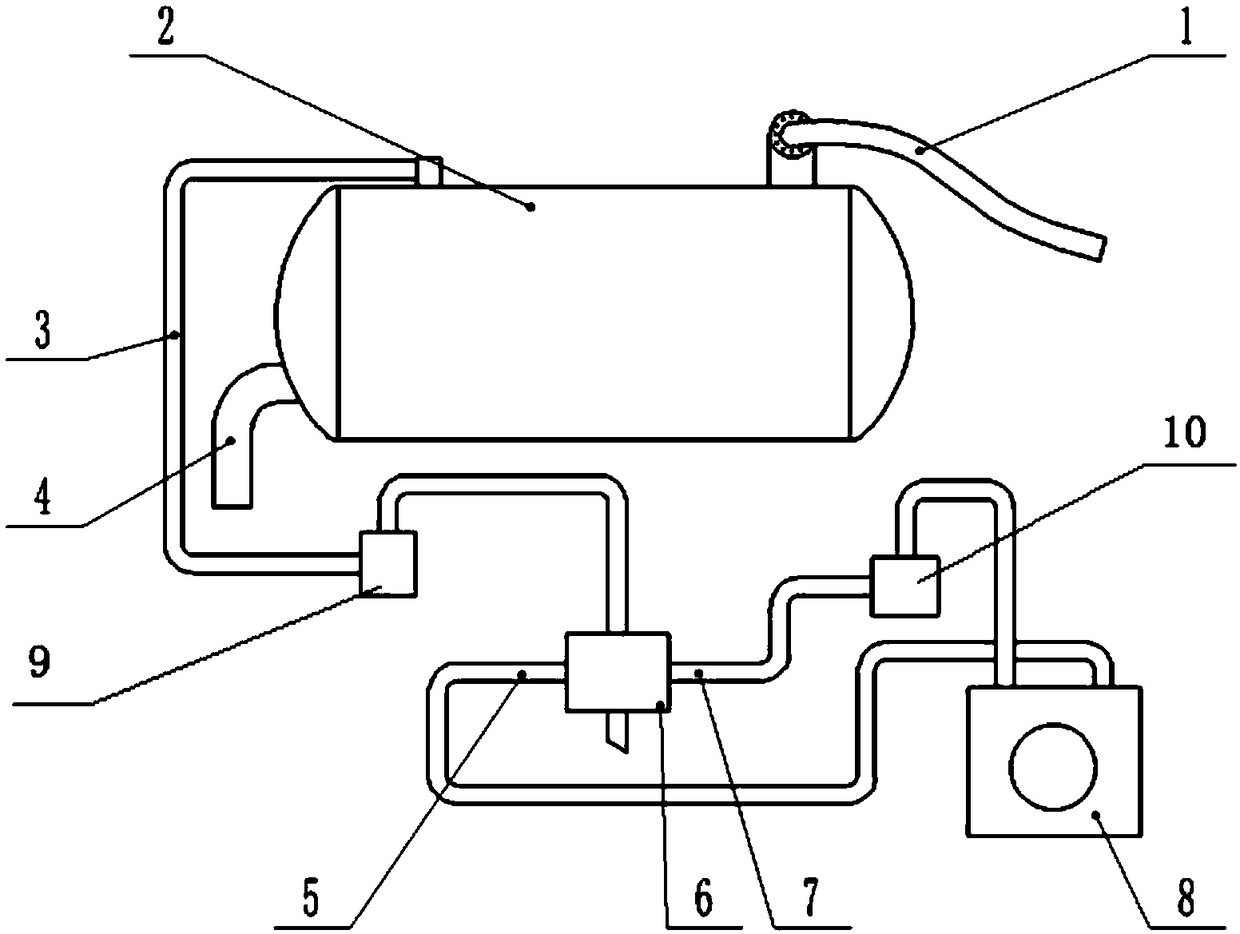

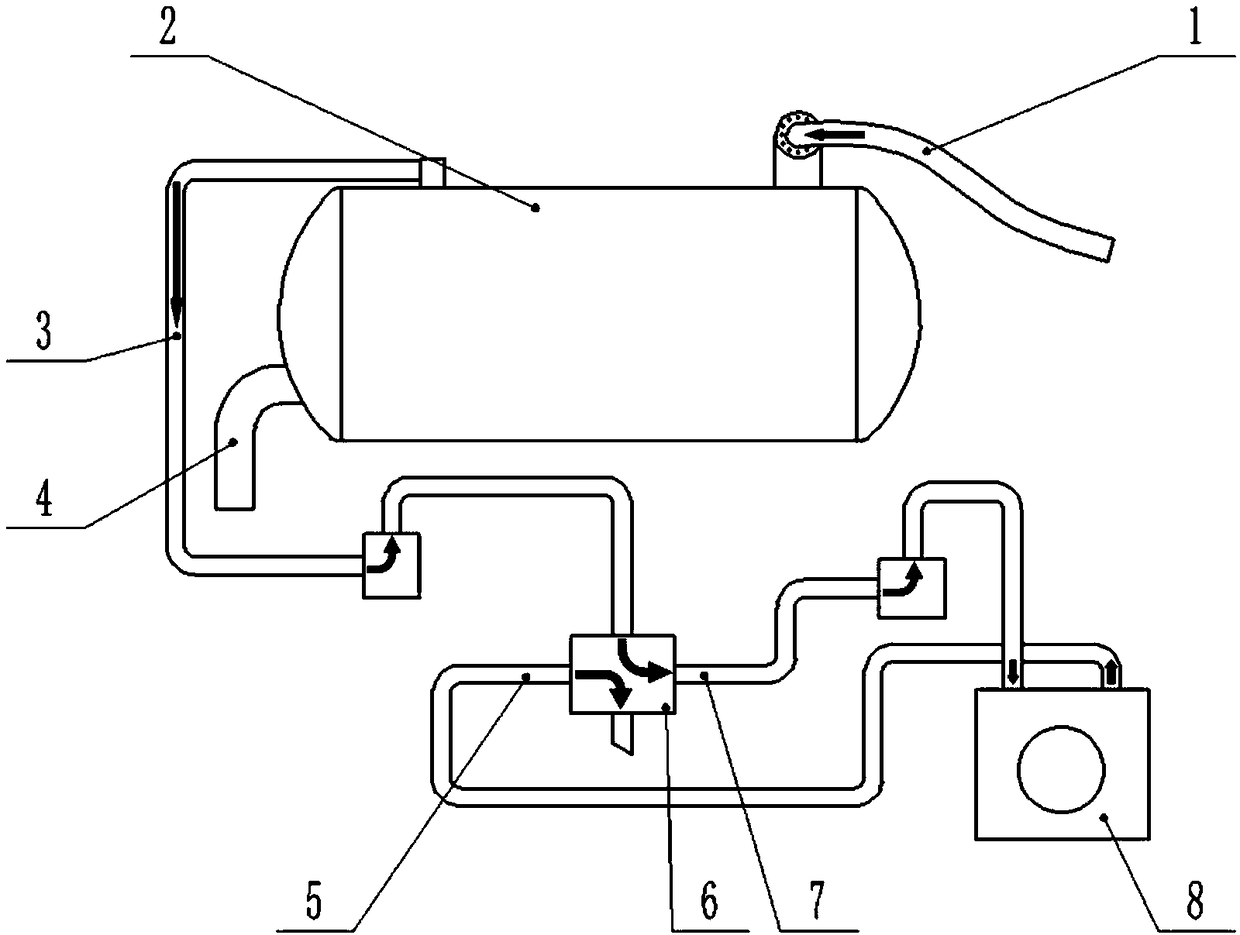

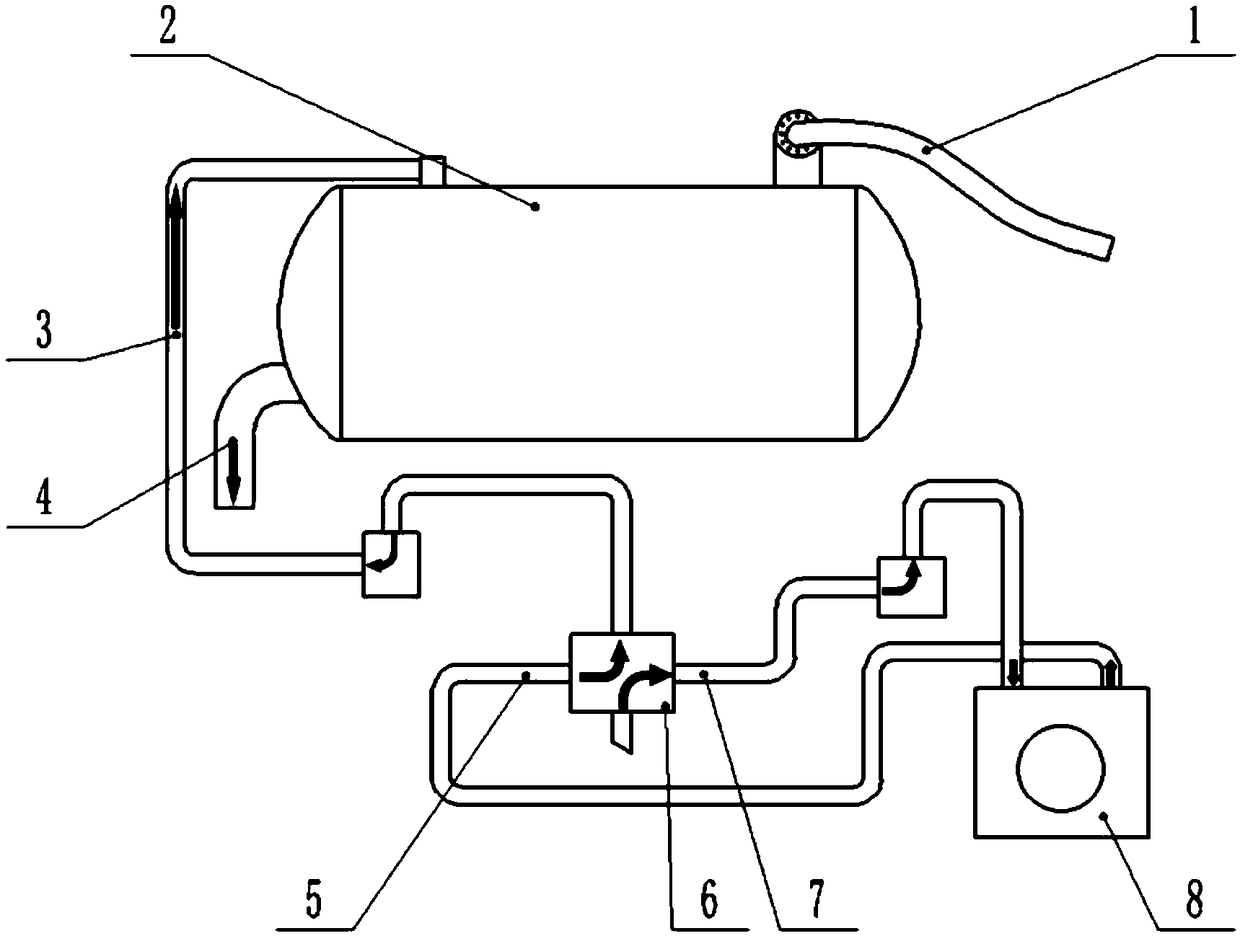

[0039] Such as Figure 1-3 As shown, the four-way valve 6 includes four valve ports, with the upper valve port being the first valve port, and the second valve port, the third valve port and the fourth valve port in turn clockwise.

[0040] The air inlet of the dry vacuum pump 8 communicates with the second valve port through the second pipe 7, and the air outlet communicates with the fourth valve port through the third pipe 5. The third valve port of the four-way valve 6 communicates with the atmosphere through a safety pipeline. The first valve port of the four-way valve 6 communicates with the sewage suction tank 2 through the first pipe 3. The first pipe 3 is provided with a safety valve 9, and the second pipe 7 is provided with a water vapor separator 10.

[0041] The upper part of the sewage suction tank 2 is provided with an anti-overflow valve, and the anti-overflow valve is in communication with the first pipe 3. The sewage suction tank 2 and the sewage suction pipe 1 ar...

Embodiment 2

[0046] A dry vacuum pump working system, reference figure 1 , No sewage suction tank 2, sewage suction pipe 1 and sewage pipe 4 are provided. The working end of the first pipe 3 is used to charge and exhaust air cushions, air cushion amusement parks, hovercraft, etc.

Embodiment 3

[0048] A suction working system. According to Embodiment 2, the working end of the first pipe 3 is connected to the valve port of a three-way valve. The other two valve ports of the three-way valve are respectively connected to two suction tanks. By switching the state of the three-way valve, the first pipe 3 can be connected to different suction tanks respectively.

[0049] The structure of the suction tank is similar to that of the sewage suction tank, but it is much smaller than the volume of the sewage suction tank. The upper part of the suction tank is connected with a suction pipe for suction, and the lower part of the suction tank is connected with a discharge pipe for discharging. The discharge pipe is equipped with a ball valve, which is closed during suction and opened during discharge.

[0050] It is also possible to provide multiple rows of solenoid valves, the first pipe 3 is connected to one end of the solenoid valve, and the other end of the solenoid valve is respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com