Detachable split efficient compressor air cylinder base and assembling method thereof

A technology for compressors and cylinder blocks, applied in the field of refrigeration compressors, can solve the problems of uneven chamfering or chamfering flanging, reduced refrigeration capacity of compressors, stuck compressor pistons, etc. The effect of flexibility and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

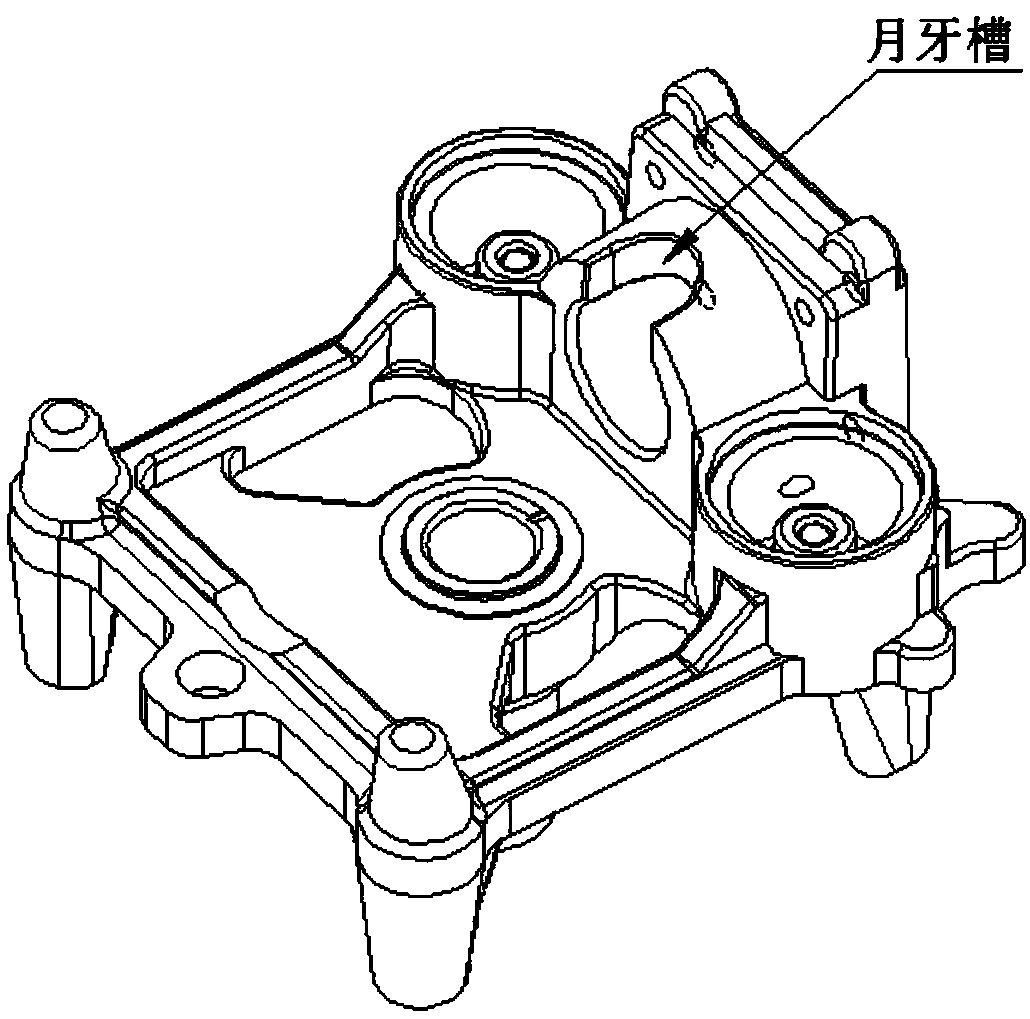

[0038] Such as Figure 2 to Figure 5 The expressed structure of the present invention is a detachable split high-efficiency compressor cylinder block, including a lower base 8 . In order to overcome the deficiencies and existing problems of the prior art, realize the invention purpose of overcoming the hidden danger of the piston of the compressor and improving the refrigeration efficiency of the compressor, the technical scheme adopted by the present invention is as follows:

[0039] The cylinder block of the detachable split high-efficiency compressor of the present invention is provided with an upper cylinder body 6, and the upper cylinder body 6 is fastened and connected to the lower base 8 by fastening screws 11 for the upper cylinder body.

[0040] In the detachable split-type high-efficiency compressor of the present invention, the split detachable cylinder block includes the upper cylinder block 6 and the lower base 8; the cylinder block technology can reduce the hidde...

Embodiment 2

[0047] Embodiment two, such as Figure 6 to Figure 8 Shown:

[0048] The present invention provides a detachable split high-efficiency compressor cylinder block, including a first-stage noise reduction lower base 16, the cylinder block is provided with a first-stage noise reduction upper cylinder body 14, and the first-stage noise reduction upper cylinder body 14 The fastening screw 11 of the upper cylinder body is accurately positioned and fastened to the lower base 16 of the first-level noise reduction; the first-level noise reduction chamber 17 and the first-level noise reduction chamber 17 are respectively arranged on both sides of the upper cylinder body 14 of the first-level noise reduction. Mholtz resonator.

[0049] One side of the first-stage anechoic chamber 17 is fastened with the coil pipe of the resistant anechoic chamber by screws.

[0050] The first-stage muffler upper cylinder 14 is provided with an exhaust muffler and a Helmertz exhaust resonant cavity respe...

Embodiment 3

[0054] Embodiment three, such as Figure 9 , Figure 10 Shown:

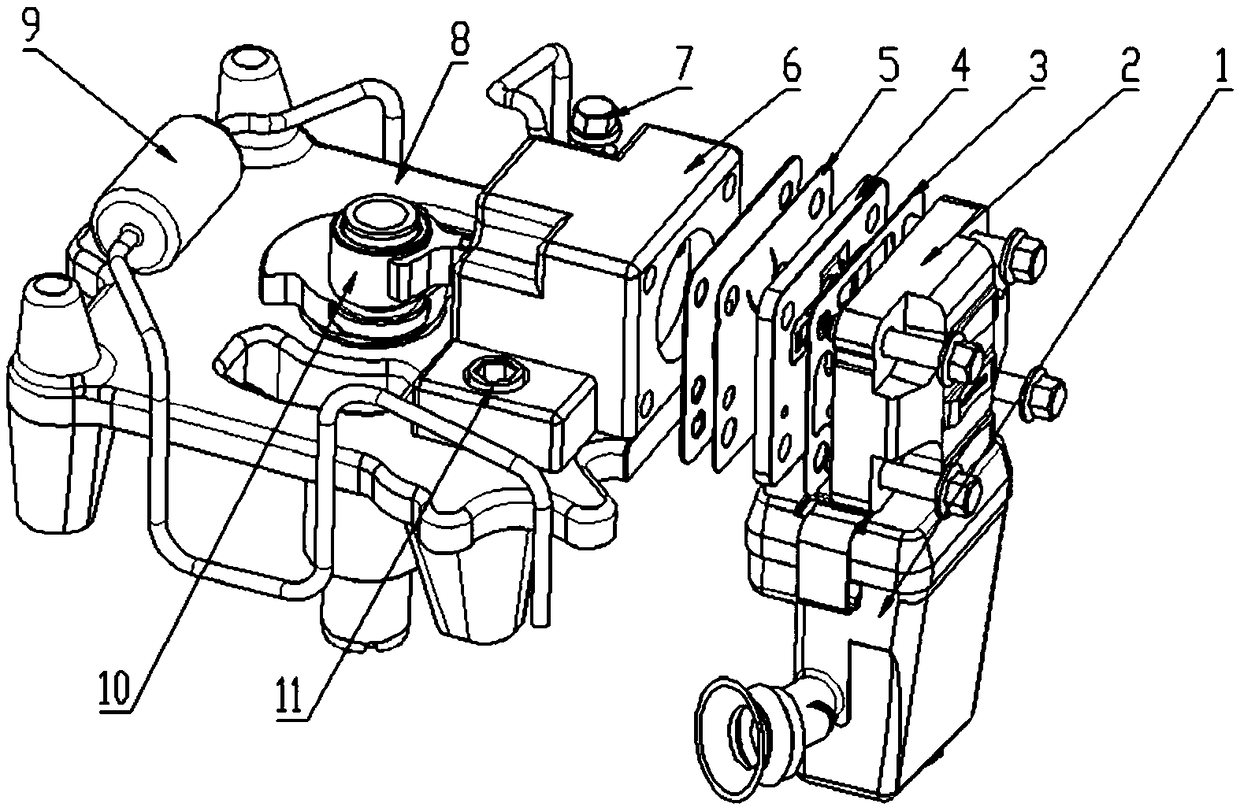

[0055] The present invention provides a detachable split high-efficiency compressor cylinder block, including a lower base 8, the cylinder block is provided with an upper cylinder body 6, and the second-stage noise reduction upper cylinder body 20 is fastened with screws through the upper cylinder body 11 is fastened to the lower base 8; the primary anechoic chamber 21 and the secondary anechoic chamber 22 are arranged on the same side of the secondary anechoic upper cylinder 20.

[0056] The cylinder head 2 of the high-efficiency compressor is connected to the upper cylinder body 6 through the sequentially arranged cylinder head gasket 3, valve plate assembly 4, suction valve plate 5, and valve plate gasket.

[0057] The high-efficiency compressor is provided with a suction muffler 1; the suction muffler 1 is installed on the suction limit side of the cylinder head 2.

[0058] The secondary anechoic chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com