Process for transforming geniposide under enzymatic action of polyurethane foam immobilized cellulase

A technology of polyurethane foam and cellulase, which is applied in the directions of enzymes, enzymes, etc., which are fixed on/in organic carriers, can solve the problems of low utilization rate and waste of cellulase, and achieve easy expansion of industrialization and low cost. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

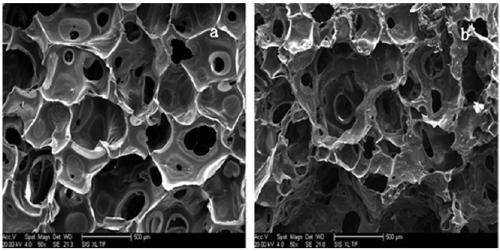

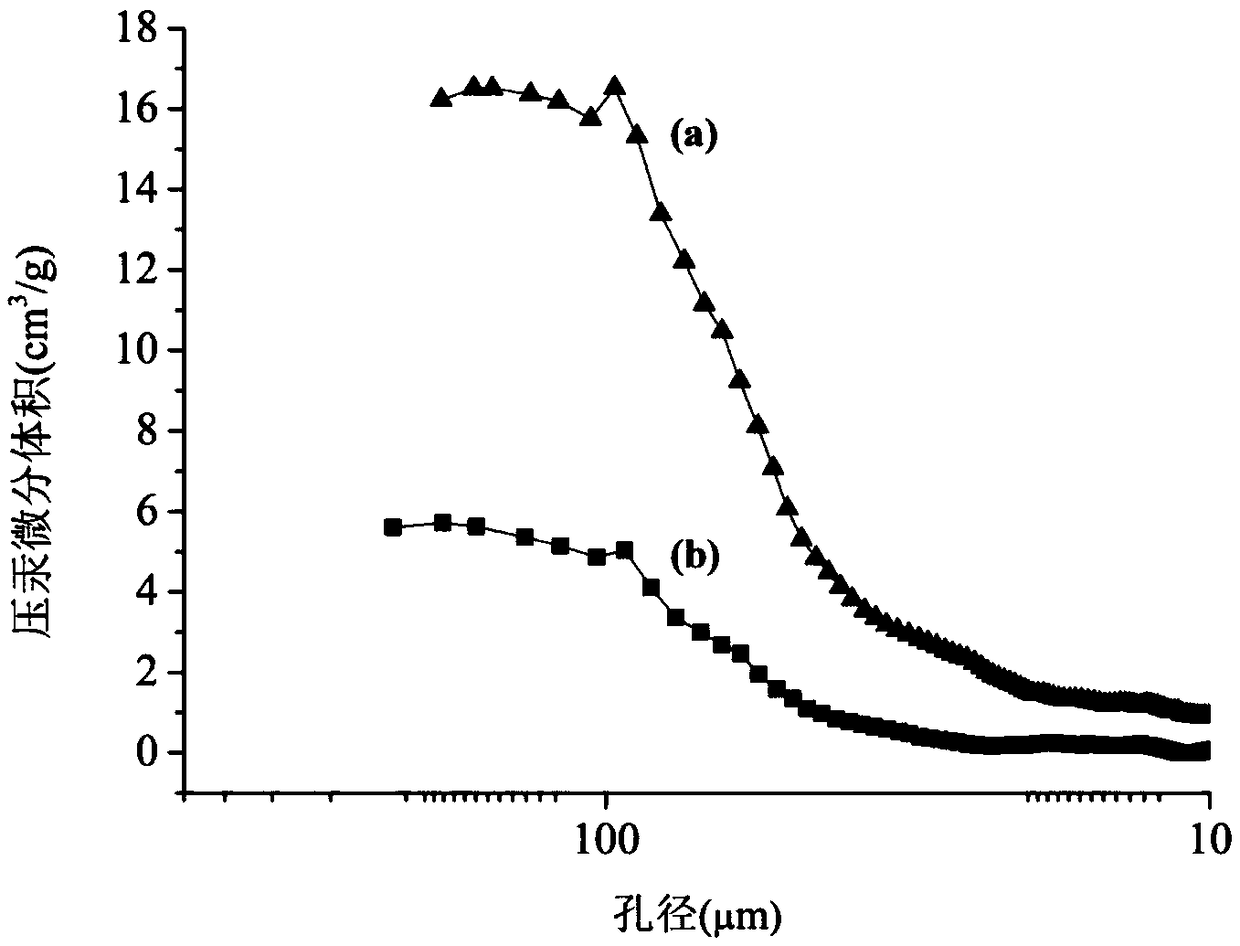

Method used

Image

Examples

example 1

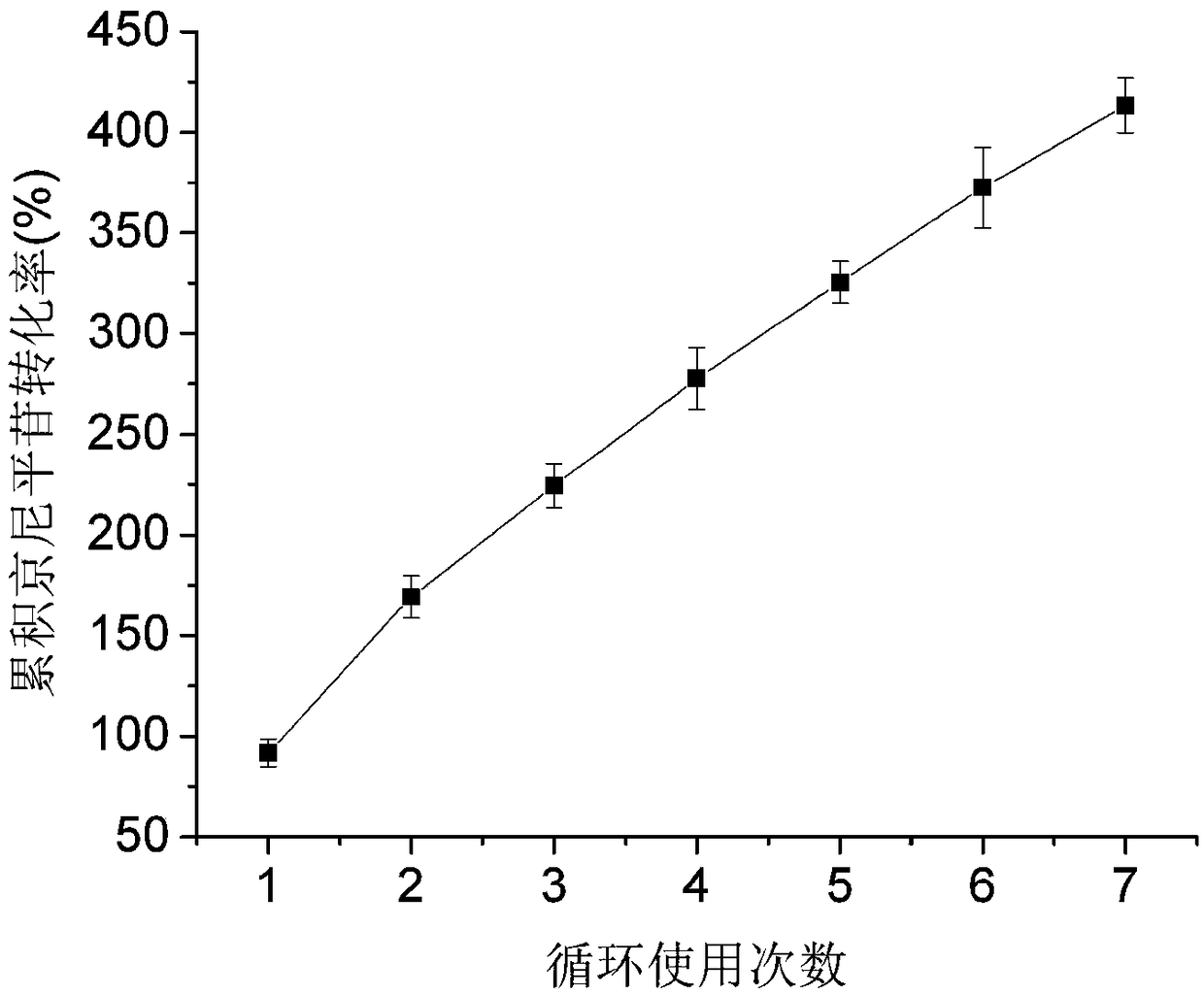

[0022] Put the powdery cellulase that mass fraction is 30.0% into the polyurethane hair of 1.3% deionized water, 37.5% polyethylene glycol 400, 0.5% Contonin DC-193, 0.6% dibutyltin dilaurate The foam material is mixed evenly, after adding 30% diphenylmethane diisocyanate, stir in a water bath at 20°C under the mechanical stirring condition of 500r / min for 20s, and then cure at room temperature for 24h, that is, the polyurethane foam can be fixed on the carrier. cellulase. Place the prepared immobilized cellulase directly in the aqueous solution of geniposide under the conditions of 35°C and pH=6, carry out the enzymatic reaction for 70 minutes, take out the immobilized cellulase, and make the After the enzyme is inactivated, the membrane is filtered and the concentration of the generated genipin solution is measured by high performance liquid chromatography, and the conversion rate of geniposide is calculated. As a result, the cumulative conversion rate of geniposide of the ...

example 2

[0024] Put the mass fraction of 27.6% cellulase into 2.1% deionized water, 35.0% polyethylene glycol 600, 0.7% Tween 80, 0.4% dibutyltin dilaurate in the polyurethane foaming material and mix Evenly, after adding 35.0% diphenylmethane diisocyanate, stir in a water bath at 20°C with a mechanical stirring speed of 500r / min for 20s, and then cure at room temperature for 24h, that is, the immobilized cellulose with polyurethane foam as the carrier enzyme. Place the prepared immobilized cellulase directly in the aqueous solution of geniposide under the conditions of 15°C and pH=3, carry out the enzymatic reaction for 70 minutes, take out the immobilized cellulase, and make the After the enzyme is inactivated, the membrane is filtered and the concentration of the generated genipin solution is measured by high performance liquid chromatography, and the conversion rate of geniposide is calculated. As a result, after 7 cycles of use, the cumulative conversion rate of geniposide of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com