Microalgae culture device

A microalgae culture and pipeline technology, applied in the biological field, can solve the problems of algal cell damage, high energy consumption, low energy consumption, etc., and achieve the effects of small algal cell damage, high density, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

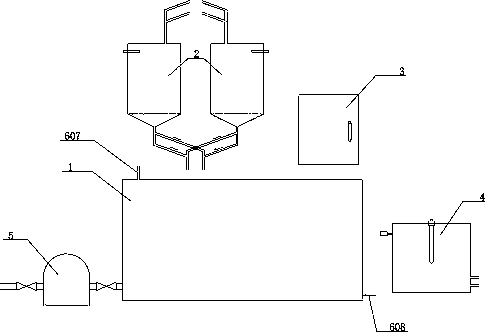

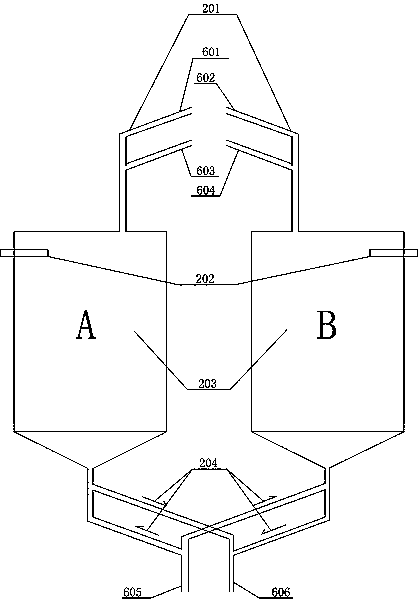

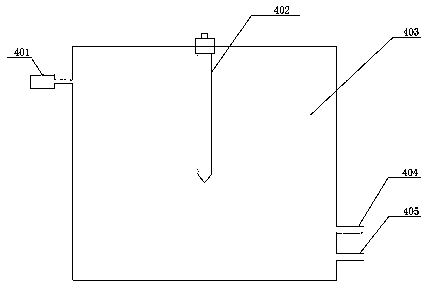

[0020] Such as Figures 1 to 3 As shown, the present invention proposes a microalgae culture device, including a closed reactor assembly 1, a negative pressure liquid storage tank 2 connected by a pipeline on the closed reactor assembly 1, and a negative pressure liquid storage tank 2 upper end pipe The control electric cabinet 3 connected by the electric circuit, the simple air purification device 4 connected by the gas circuit solenoid valve on the control electric cabinet 3, and the auxiliary water pump 5 connected to one end of the closed reactor assembly 1; the negative pressure liquid storage tank 2 includes negative pressure The pressure liquid storage tank 203A and the negative pressure liquid storage tank 203B, and the lower part is designed as a cone bottom; the upper end of the negative pressure liquid storage tank 2 is provided with a gas line pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com