Environment-friendly bulk molding compound and preparation method thereof

An environmentally friendly technology for bulk molding compounds, applied in the field of bulk molding compounds, which can solve problems such as environmental pollution, high vapor pressure, and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

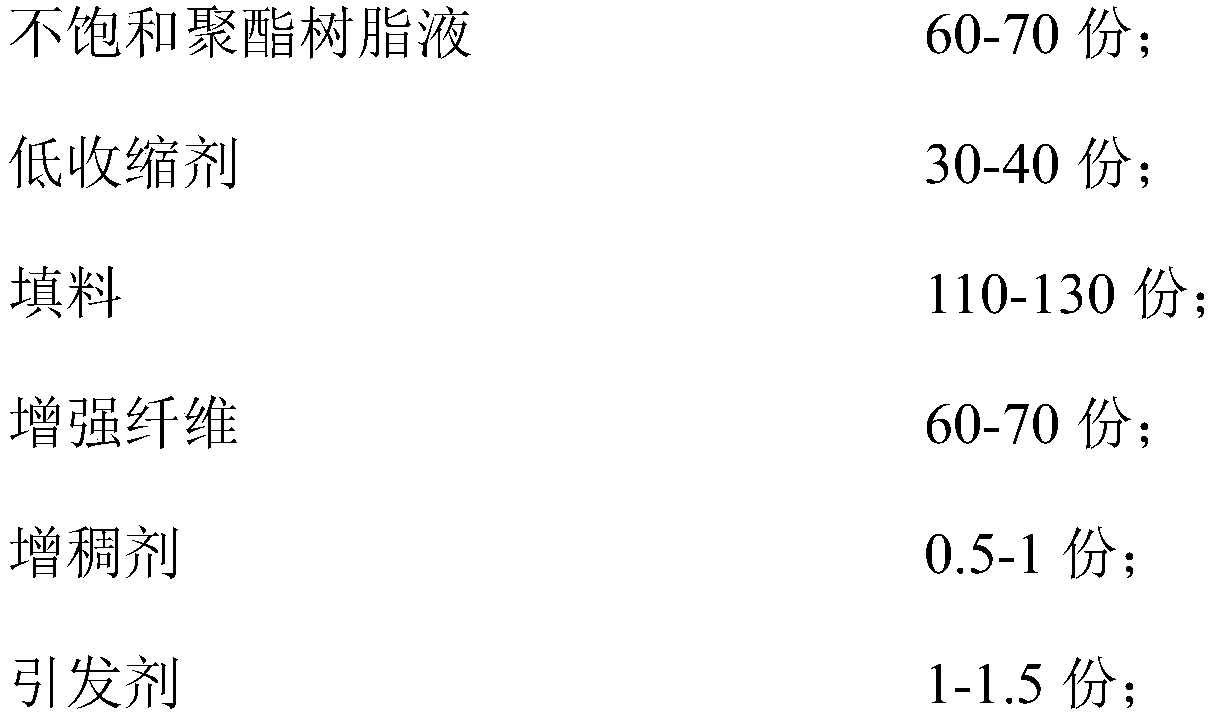

[0051] This embodiment provides an environment-friendly bulk molding compound, which includes the following raw material components in parts by weight:

[0052]

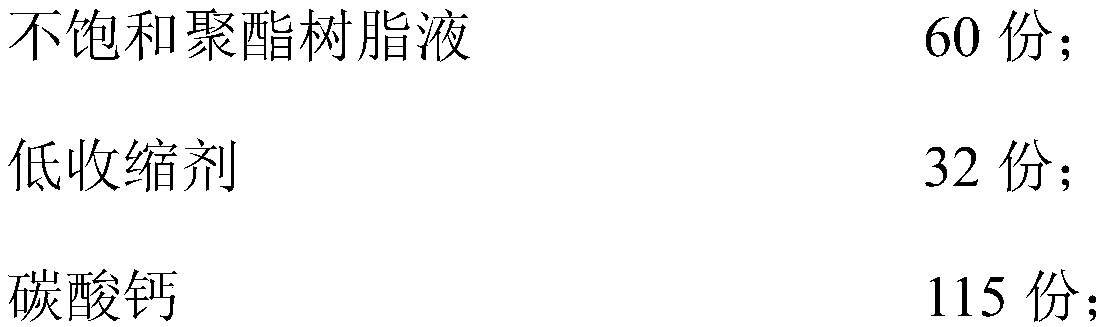

[0053]

[0054] Wherein, the unsaturated polyester resin liquid is composed of ethylene glycol phthalate and cyclohexyl methacrylate in a mass ratio of 70:30, and the low shrinkage agent is composed of polystyrene and methyl methacrylate in a mass ratio of 45: 55 components, the length of the alkali-free glass fiber is 12mm.

[0055] The preparation method of the above-mentioned environment-friendly bulk molding compound is as follows:

[0056] (1) Add polystyrene powder and methyl methacrylate into a high-speed disperser, mix at a speed of 500r / min for 60min, and stand at 20°C for 24h to obtain a low-shrinkage agent;

[0057] (2) Add the unsaturated polyester resin liquid, the low-shrinkage agent and the initiator obtained in step (1) into a high-speed disperser, and mix for 4 minutes at a rotating speed of 9...

Embodiment 2

[0060] This embodiment provides an environment-friendly bulk molding compound, which includes the following raw material components in parts by weight:

[0061]

[0062]

[0063] Among them, the unsaturated polyester resin liquid is composed of propylene glycol isophthalate and methylcyclohexyl methacrylate in a mass ratio of 60:40, and the low shrinkage agent is composed of polystyrene and methyl acrylate in a mass ratio of 40:60 , the length of the alkali-free glass fiber is 6 mm, and the mesh number of the zinc stearate powder is 200 mesh.

[0064] The preparation method of the above-mentioned environment-friendly bulk molding compound is as follows:

[0065] (1) Add polystyrene powder and methyl acrylate into a high-speed disperser, mix at a speed of 800r / min for 30min, and stand at 30°C for 12h to obtain a low-shrinkage agent;

[0066] (2) Add the unsaturated polyester resin liquid, the low-shrinkage agent, initiator and sizing agent obtained in step (1) into a hig...

Embodiment 3

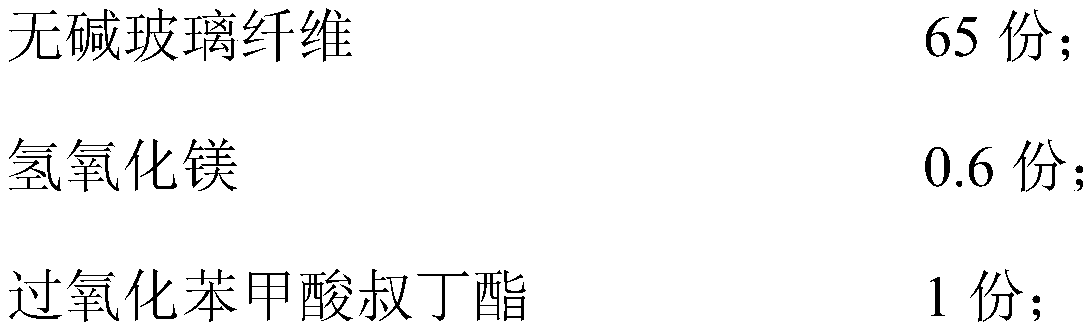

[0069] This embodiment provides an environment-friendly bulk molding compound, which includes the following raw material components in parts by weight:

[0070]

[0071] Among them, the unsaturated polyester resin liquid is composed of neopentyl glycol isophthalate and cyclohexyl methacrylate in a mass ratio of 65:35, and the low shrinkage agent is composed of polystyrene and ethyl methacrylate in a mass ratio of 42 : 58 composition, the length of alkali-free glass fiber is 10mm, and the order number of zinc stearate powder is 500 orders.

[0072] The preparation method of the above-mentioned environment-friendly bulk molding compound is as follows:

[0073] (1) Add polystyrene powder and ethyl methacrylate to a high-speed disperser, mix at a speed of 600r / min for 45min, and stand at 25°C for 18h to obtain a low-shrinkage agent;

[0074] (2) Add the unsaturated polyester resin liquid, the low-shrinkage agent obtained in step (1), the initiator and the sizing agent into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com