Modified laterite-nickel ore slag for flame-retardant reinforced rubber filler

A technology for reinforcing rubber and laterite nickel, which is applied in the field of modified laterite nickel slag and its preparation for flame-retardant reinforcing rubber fillers, can solve the problems of poor compatibility, single performance, and easy agglomeration, and achieve synergy, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

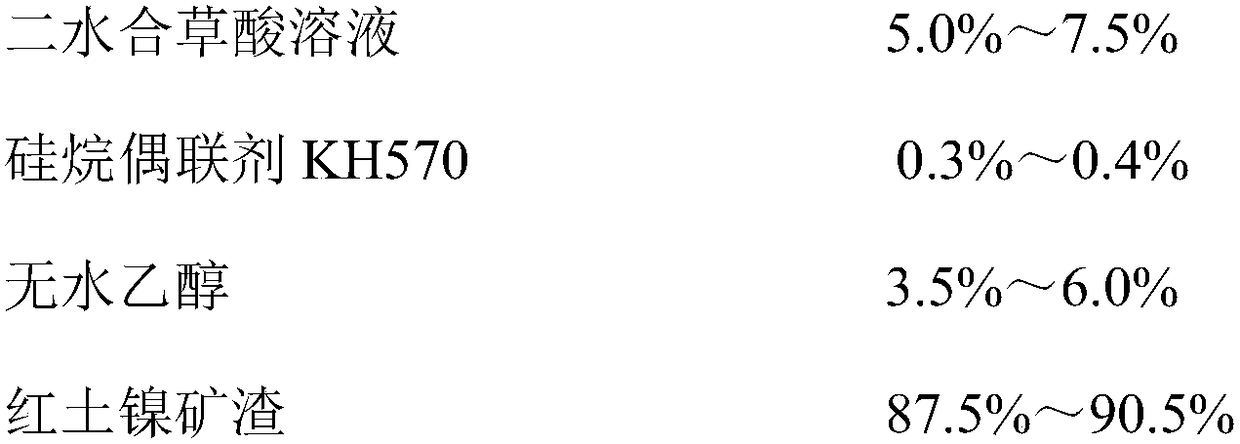

[0021] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0022]

[0023] The mass fraction of the dihydrate oxalic acid solution is 90%; the silane coupling agent KH570 is industrially pure; the dehydrated alcohol is analytically pure; the particle size of the laterite nickel slag is 3.6 μm to 98.2 μm, and the chemical composition (mass fraction) for SiO 2 (28.31%), FeO (0.66%), Al 2 o 3 (25.64%), CaO (27.94%), MgO (9.81%), Cr 2 o 3 (0.75%), MnO (2.02%) and others (4.87%).

[0024] First, mix dihydrate oxalic acid solution with laterite nickel slag, stir it for 7 hours with a constant temperature magnetic stirrer at a stirring temperature of 65°C and a stirring speed of 800r / min, then add silane coupling agent KH570, anhydrous Ethanol was stirred for 2.5 hours with a constant temperature magnetic stirrer at a stirring temperature of 50° C. and a stirring speed of 500 r / min to obtain modi...

Embodiment 2

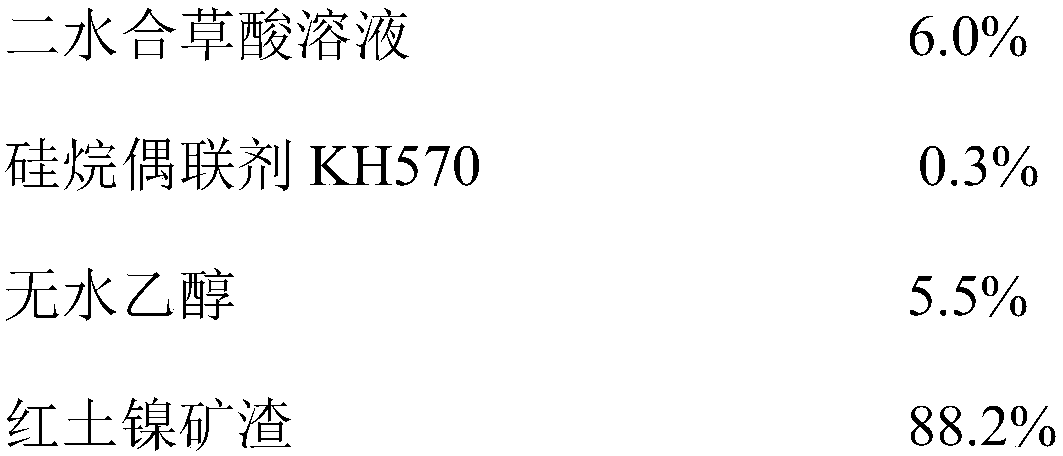

[0026] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0027]

[0028] The mass fraction of the dihydrate oxalic acid solution is 80%; the silane coupling agent KH570 is industrially pure; the dehydrated alcohol is analytically pure; the particle size of the laterite nickel slag is 3.2 μm to 96.9 μm, and the chemical composition (mass fraction) for SiO 2 (28.15%), FeO (0.79%), Al 2 o 3 (26.52%), CaO (27.51%), MgO (10.29%), Cr 2 o 3 (0.77%), MnO (1.86%) and others (4.11%).

[0029] First, mix the dihydrate oxalic acid solution with the laterite nickel slag, and stir it for 10 hours with a constant temperature magnetic stirrer at a stirring temperature of 75°C and a stirring speed of 700r / min, and then add silane coupling agent KH570, anhydrous Ethanol was stirred for 1.5 h with a constant temperature magnetic stirrer at a stirring temperature of 40° C. and a stirring speed of 700 r / min ...

Embodiment 3

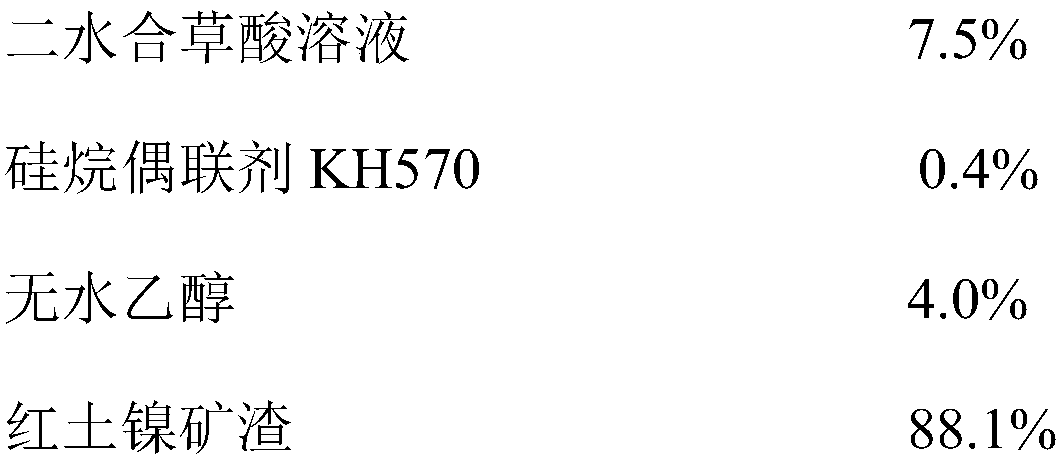

[0031] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0032]

[0033] The mass fraction of the dihydrated oxalic acid solution is 95%; the silane coupling agent KH570 is industrially pure; the dehydrated alcohol is analytically pure; the particle size of the laterite nickel slag is 4.4 μm to 101.8 μm, and the chemical composition (mass fraction) for SiO 2 (28.55%), FeO (0.59%), Al 2 o 3 (26.57%), CaO (27.67%), MgO (10.33%), Cr 2 o 3 (0.59%), MnO (1.56%) and others (4.14%).

[0034] First, mix dihydrate oxalic acid solution with laterite nickel slag, stir it for 9 hours with a constant temperature magnetic stirrer at a stirring temperature of 60°C and a stirring speed of 900r / min, then add silane coupling agent KH570, anhydrous Ethanol was stirred for 3 hours with a constant temperature magnetic stirrer at a stirring temperature of 30° C. and a stirring speed of 400 r / min to obtain mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com