A kind of purification process of haemophilus b-type polysaccharide

A Haemophilus, b-type technology, applied in the field of polysaccharide vaccines, can solve problems such as environmental hazards, user health hazards, corrosion, etc., to prevent environmental and personnel hazards, reduce flammable and explosive hazards, and avoid phenol The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Dissolve the crude polysaccharide in PB buffer, and perform ultrafiltration using a tangential flow ultrafiltration membrane bag to obtain an ultrafiltration solution:

[0029] Use a concentration of 5mmol / L, pH6.5 phosphate buffer to dissolve the crude polysaccharide to a concentration of 5mg / mL, the ultrafiltration volume is 10 times the volume of the crude polysaccharide solution, the temperature is controlled at 8°C, and the tangential flow ultrafiltration membrane The package model is 30KD.

[0030] 2) The ultrafiltration solution is chromatographed through a ceramic hydroxyapatite column to obtain a chromatographic solution:

[0031] Load the ultrafiltration solution onto the ceramic hydroxyapatite chromatography column, collect the flow-through peak displayed at 206nm to obtain the chromatographic fluid, and use high-concentration PB buffer to elute protein and nucleic acid; the height range of the hydroxyapatite column is 16cm , the loading volume is 0.5CV (...

Embodiment 2

[0037] 1) Dissolve the crude polysaccharide in PB buffer, and perform ultrafiltration using a tangential flow ultrafiltration membrane bag to obtain an ultrafiltration solution:

[0038] Use a concentration of 15mmol / L, pH 8 phosphate buffer to dissolve the crude polysaccharide to a concentration of 10mg / mL, the ultrafiltration volume is 50 times the volume of the crude polysaccharide solution, the temperature is controlled at 15°C, and the tangential flow ultrafiltration membrane The model is 300KD.

[0039] 2) The ultrafiltration solution is chromatographed through a ceramic hydroxyapatite column to obtain a chromatographic solution:

[0040] Load the ultrafiltration solution onto the ceramic hydroxyapatite chromatography column, collect the flow-through peak displayed at 206nm to obtain the chromatographic fluid, and use high-concentration PB buffer to elute protein and nucleic acid; the height range of the hydroxyapatite column is 24cm , the loading volume is 1.5CV (colum...

Embodiment 3

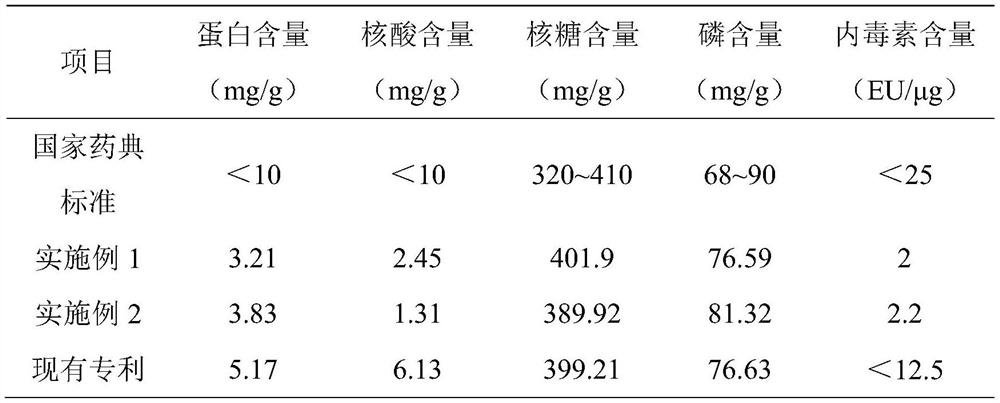

[0046] The various indicators of Haemophilus type b polysaccharide obtained by the process of the present invention are compared with the national pharmacopoeia and existing patents (patent number: CN201210037245.2) and the results are as follows:

[0047] It can be found that all indicators of the Haemophilus type b polysaccharide obtained by this process meet the requirements of the National Pharmacopoeia, and the content of protein and nucleic acid is lower than that of the polysaccharide obtained by the existing patented method.

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com