Method for degrading antibiotics and heavy metals in excrement of livestock

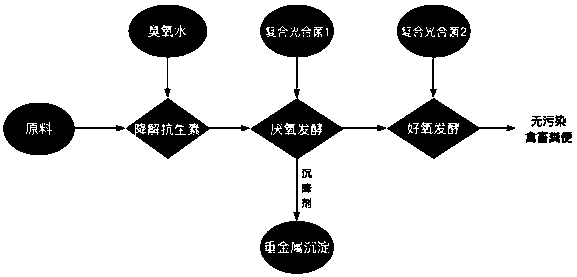

A technology of livestock and poultry manure and antibiotics, applied in organic fertilizers, climate change adaptation, fertilization devices, etc., can solve the problems of inability to separate heavy metals, environmental temperature effects, long treatment periods, etc., and achieve fast and efficient ozone action and high treatment efficiency. , does not produce the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for degrading antibiotics and heavy metals in livestock and poultry manure, comprising the following steps:

[0032] a) Mix and stir 100g of collected cow dung and ozone water with a concentration of 10ppm for 30min at a ratio of 1:1 to obtain mixture A.

[0033] b) Mixture A was inoculated with Rhodopseudomonas palustris for anaerobic fermentation to obtain fermentation product B. The anaerobic fermentation conditions were light of 2000 lux, fermentation temperature of 40°C, pH value of 7, inoculum amount of 20g / L, and bacterial age It is the growth index phase, and the fermentation time is 90min.

[0034] c) Add 50mg / L polyaluminium chloride to the fermentation product B, and obtain the fermentation broth C after filtration. Promote the flocculation of photosynthetic bacteria that have adsorbed heavy metal ions, and completely remove heavy metal elements from the fermentation broth.

[0035] d) Fermentation broth C was inoculated with Rhodobacter sphaericus...

Embodiment 2

[0037] A method for degrading antibiotics and heavy metals in livestock and poultry manure, comprising the following steps:

[0038] a) Mix 200g of collected chicken manure with ozone water at a concentration of 20ppm and stir for 120min at a material-to-liquid ratio of 1:5 to obtain mixture A.

[0039] b) Mixture A was inoculated with 50% Rhodopseudomonas palustris, 20% Rhodobacter sphaericus and 30% Rhodobacter capsularis in mixture A for anaerobic fermentation to obtain fermentation product B. The anaerobic fermentation conditions were light 5000lux, fermentation temperature The temperature is 30°C, the pH value is 6, the inoculum amount is 30g / L, the bacterial age is in the growth exponential phase, and the fermentation time is 30min.

[0040] c) Add 90 mg / L polyaluminum chloride to the fermentation product B, and obtain fermentation broth C after filtration. Promote the flocculation of photosynthetic bacteria that have adsorbed heavy metal ions, and completely remove hea...

Embodiment 3

[0043] A method for degrading antibiotics and heavy metals in livestock and poultry manure, comprising the following steps:

[0044] a) Mix and stir 200g of collected pig manure and ozone water with a concentration of 0.5ppm for 90min at a ratio of 1:10 to obtain mixture A.

[0045] b) Mixture A was inoculated with 80% by weight of Rhodopseudomonas palustris and 20% of Rhodobacter capsulata for anaerobic fermentation to obtain fermentation product B. The anaerobic fermentation conditions were light of 4000 lux, fermentation temperature of 40°C, and pH of 8. The inoculation amount is 0.5g / L, the age of the bacteria is in the exponential growth period, and the fermentation time is 90min.

[0046]c) Add 80 mg / L polyacrylamide to fermentation product B, and obtain fermentation broth C after filtration. Promote the flocculation of photosynthetic bacteria that have adsorbed heavy metal ions, and completely remove heavy metal elements from the fermentation broth.

[0047] d) Fermen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com