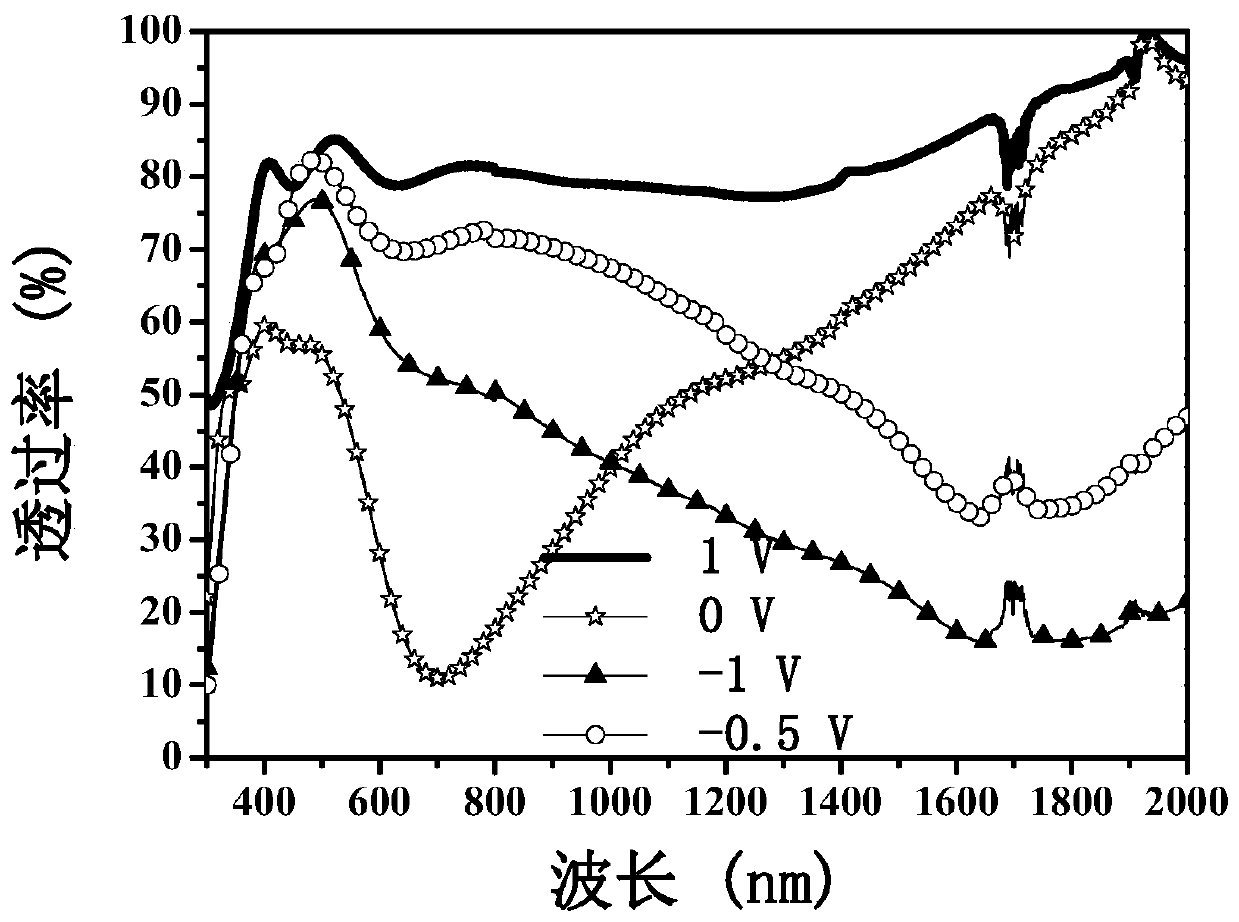

A kind of Prussian blue/tungsten trioxide electrochromic thin film and preparation method thereof

A technology of tungsten trioxide and Prussian blue, applied in the direction of tungsten oxide/tungsten hydroxide, ferricyanide, metal cyanide, etc., can solve the problem of inability to selectively adjust light and heat in the visible and near-infrared bands, low coloring efficiency, Long discoloration time and other problems, to improve coloring efficiency, facilitate embedding and detachment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Clean the substrate: Clean the glass slide and ITO conductive glass sequentially with acetone, ethanol, and deionized water for 30 minutes, and then dry them with a plasma cleaner for 3 minutes to obtain clean glass slides and ITO conductive glass;

[0050] (2) Prepare the template:

[0051] a. Drop the suspension containing polystyrene microspheres onto the clean glass slide of step (1) to flatten, and dry to obtain a glass slide with polystyrene microspheres; the polystyrene microspheres in the suspension The spherical particle size is 500nm;

[0052] b. Put the glass slide flat on the water surface, pick up the polystyrene microspheres with the clean ITO conductive glass in step (1), and heat at 110°C for 1 min to obtain a polystyrene template with a single layer of polystyrene microspheres spread ;

[0053] (3) Electrochemical deposition of tungsten trioxide film: Dissolve sodium tungstate, hydrogen peroxide and hydrochloric acid in water to form an electrodep...

Embodiment 2

[0059] (1) Clean the substrate: Clean the glass slide and FTO conductive glass sequentially with acetone, ethanol, and deionized water for 40 minutes, and then dry them with a plasma cleaner for 1 minute to obtain clean glass slides and FTO conductive glass;

[0060] (2) Prepare the template:

[0061] a. Drop the suspension containing polystyrene microspheres onto the clean glass slide of step (1) to flatten, and dry to obtain a glass slide with polystyrene microspheres; the polystyrene microspheres in the suspension The spherical particle size is 200nm;

[0062] b. Put the glass slide flat on the water surface, pick up the polystyrene microspheres with the clean FTO conductive glass in step (1), and heat at 100°C for 3 minutes to obtain a polystyrene template with a single layer of polystyrene microspheres spread ;

[0063] (3) Electrochemical deposition of tungsten trioxide film: Dissolve sodium tungstate, hydrogen peroxide and hydrochloric acid in water to form an electro...

Embodiment 3

[0067] (1) Clean the substrate: Clean the glass slide and ITO conductive glass sequentially with acetone, ethanol, and deionized water for 20 minutes, and then dry them with a plasma cleaner for 10 minutes to obtain clean glass slides and ITO conductive glass;

[0068] (2) Prepare the template:

[0069] a. Drop the suspension containing polystyrene microspheres onto the clean glass slide of step (1) to flatten, and dry to obtain a glass slide with polystyrene microspheres; the polystyrene microspheres in the suspension The spherical particle size is 2μm;

[0070] b. Put the glass slide flat on the water surface, pick up the polystyrene microspheres with the clean ITO conductive glass in step (1), and heat at 90°C for 5 minutes to obtain a polystyrene template with a single layer of polystyrene microspheres spread ;

[0071] (3) Electrochemical deposition of tungsten trioxide film: Dissolve sodium tungstate, hydrogen peroxide and hydrochloric acid in water to form an electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com