Clean and efficient pottery grinding production line

A production line and high-efficiency technology, applied in the direction of grinding machines, grinding drive devices, grinding machine parts, etc., can solve the problems of low dust filtration recovery rate, increased production management difficulty, scattered equipment stations, etc., and achieve simple and reliable structure , Easy production management, compact layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

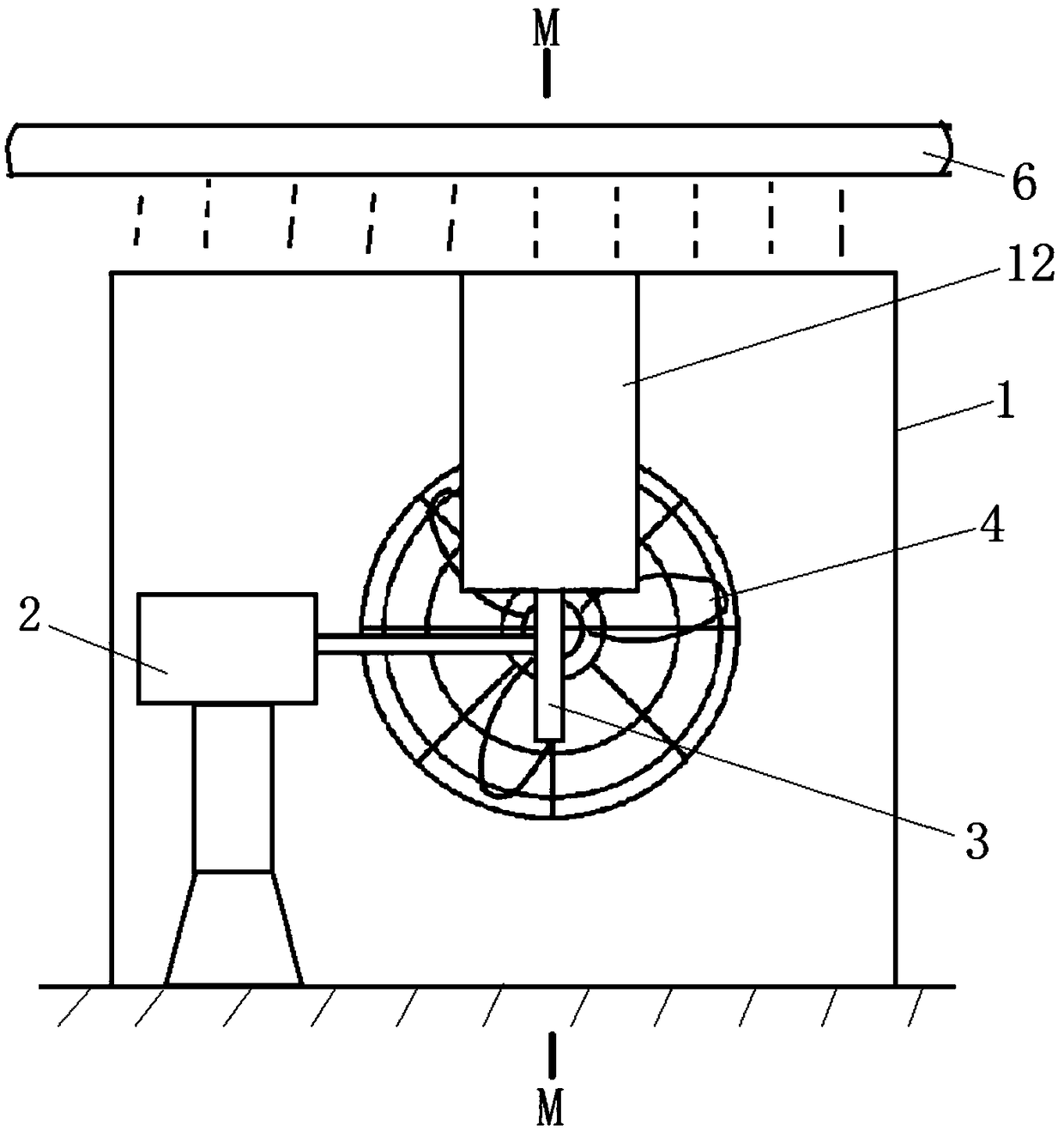

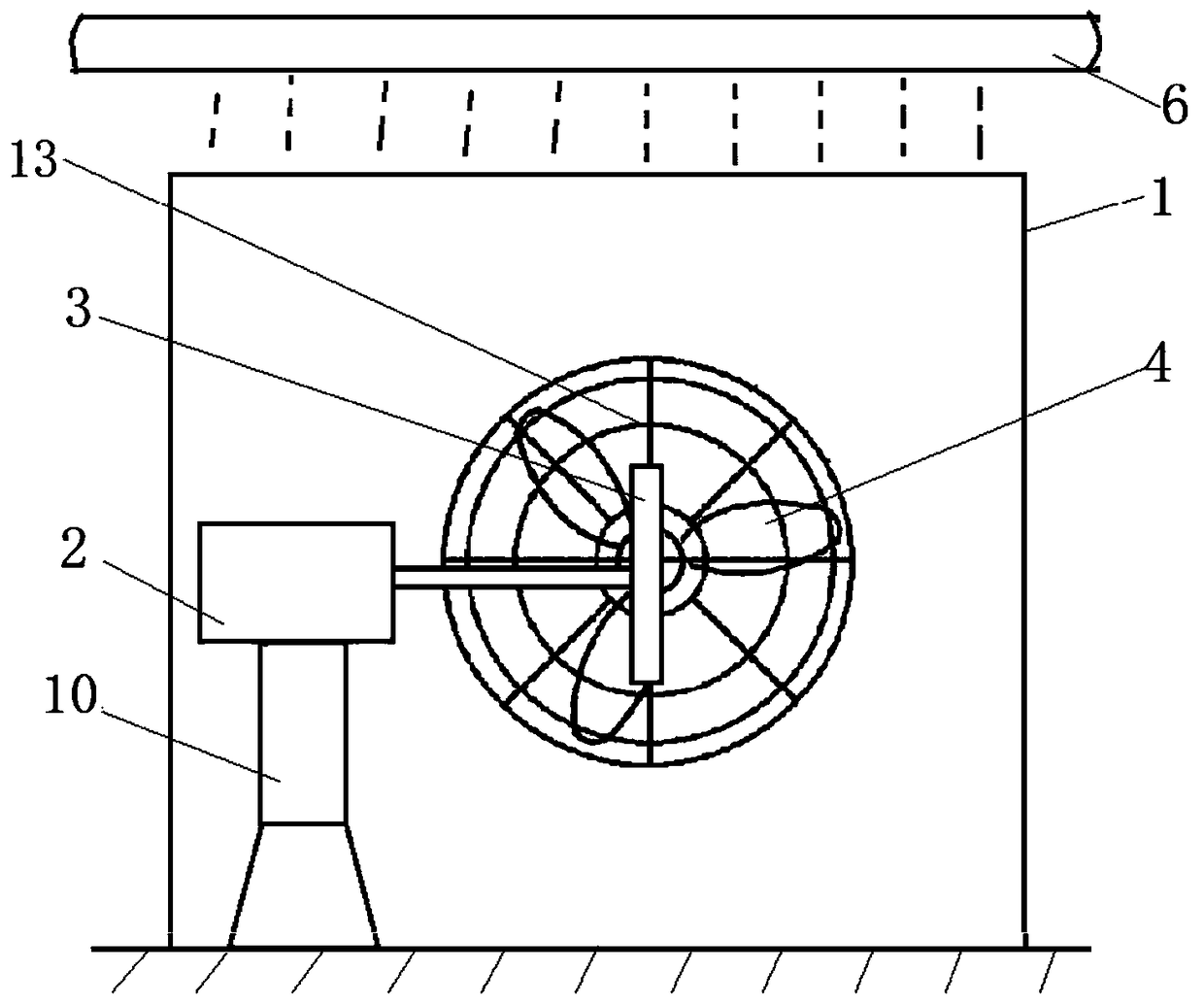

[0028] A clean and efficient pottery polishing production line is composed of one or more than two production units, such as Figure 1 ~ Figure 3 As shown, it includes the outer cover box 1 with a rectangular opening on the front, the grinding equipment installed at the front end of the outer cover box, the axial flow fan 4 installed at the rear of the outer cover box, and the filter element 5 installed at the rear of the outlet of the axial flow fan , the horizontal water inlet pipe 6 that is arranged on the top of the filter element to spray water to the filter element, and the water filter tank 7 that is arranged under the filter element. The outer cover box 1 is made of stainless steel plate. The grinding equipment includes a driving motor 2a and a grinding wheel 2b installed on the output shaft of the motor. The driving motor and the grinding wheel are all placed in the front part of the outer cover box, and the protective baffle 12 inclined forward and positioned above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com