Workbench for broaching machine tool

A workbench and machine tool technology, applied in the field of CNC machine tools, can solve the problems of high requirements for processing equipment, cumbersome processing processes, labor and time-consuming efficiency, etc., and achieve the effect of reducing processing equipment requirements, ensuring processing quality, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

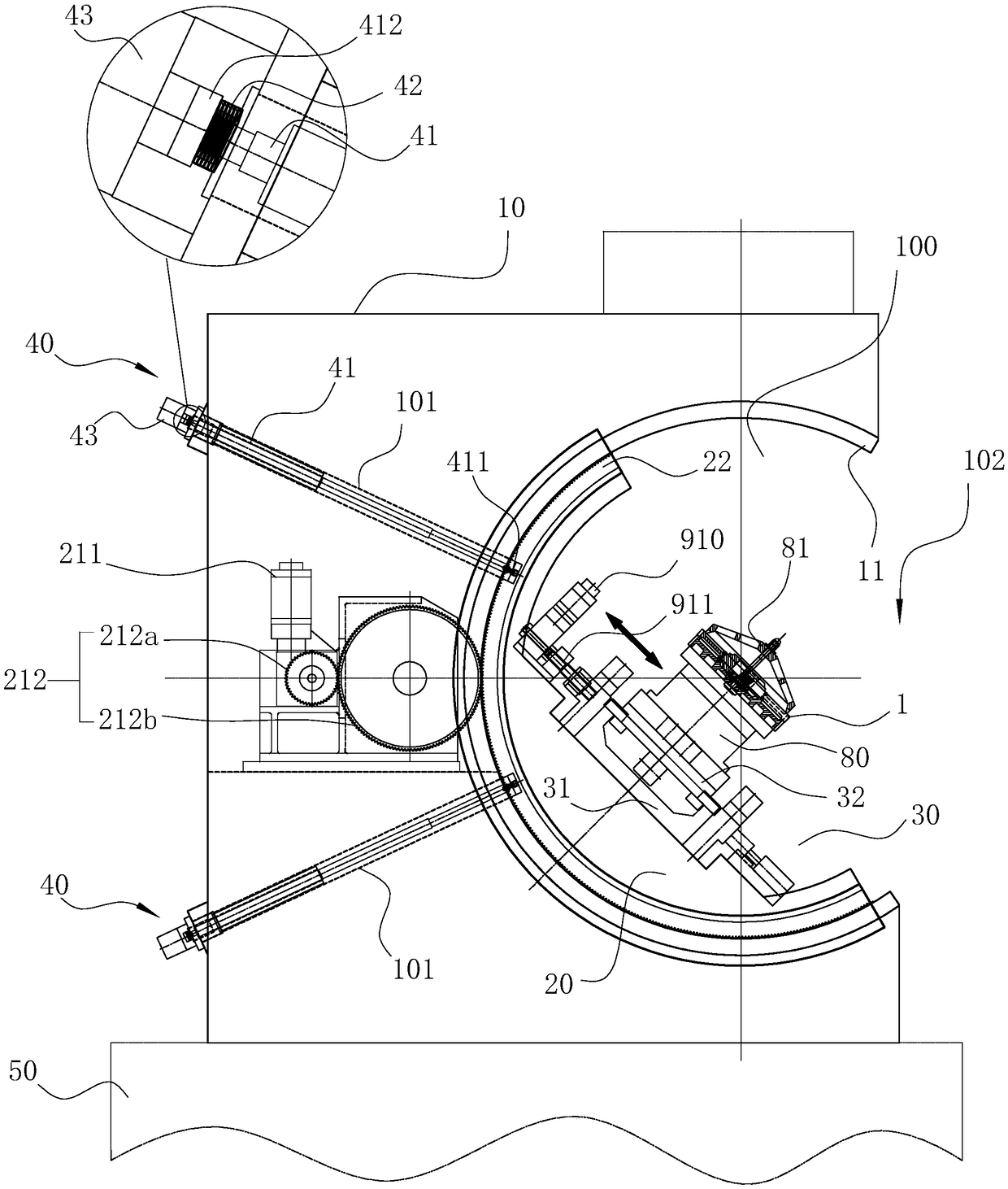

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

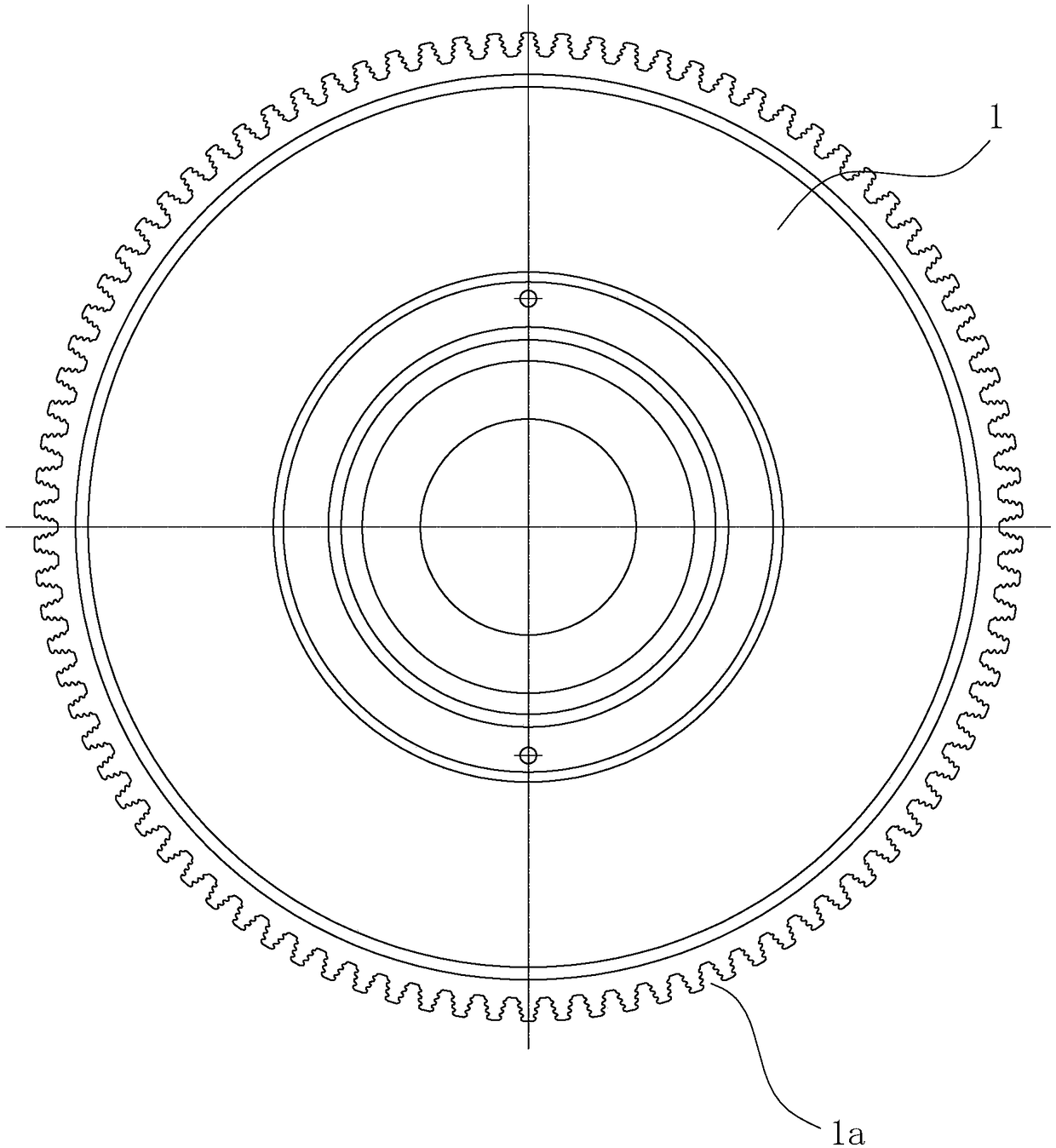

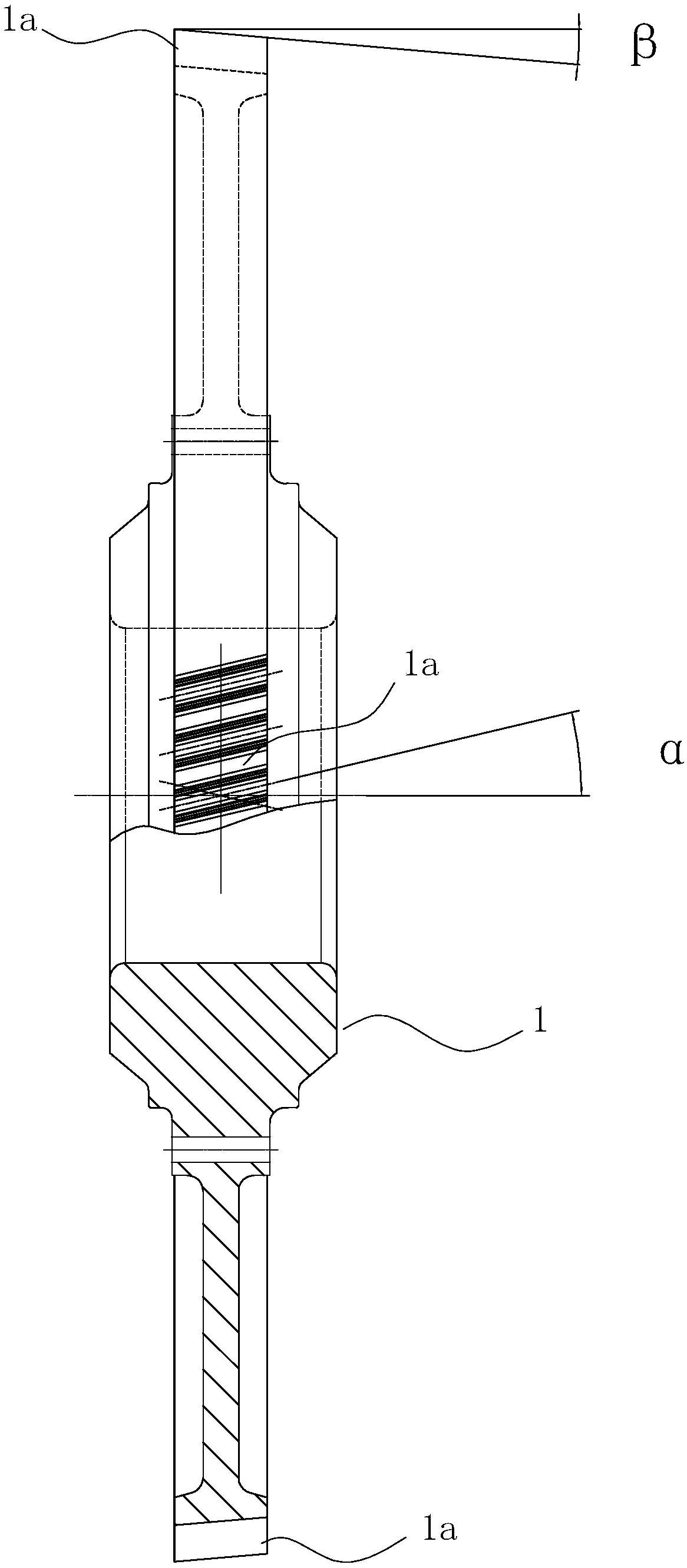

[0028] see Figure 3-Figure 11, the workbench applied to the broaching machine tool includes a fixed base 10, an arc-shaped sliding seat 20 and a sliding table mechanism 30, wherein the sliding table mechanism 30 is arranged on the arc-shaped sliding seat 20, and the arc-shaped sliding seat 20 is slidably connected On the fixed base 10 , wherein the workpiece to be processed is fixed on the sliding table mechanism 30 and can rotate together with the arc-shaped sliding seat 20 . The arc-shaped chute 100, the inner wall of the arc-shaped chute 100 is an arc-shaped wall recessed inward from top to bottom, wherein, the outer wall surface of the arc-shaped sliding seat 20 is the same as the arc-shaped wall of the arc-shaped chute 100. On the curved surface with the same radian size, two first curved guide rails 11 are correspondingly arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com