A method for preparing stevia polyphenols by composite chitosan flocculation method

A technology of chitosan and quaternary ammonium salt chitosan is applied in the directions of medical preparations, pharmaceutical formulations, sugar derivatives, etc. containing active ingredients, to achieve the effects of short flocculation time, low temperature and high flocculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

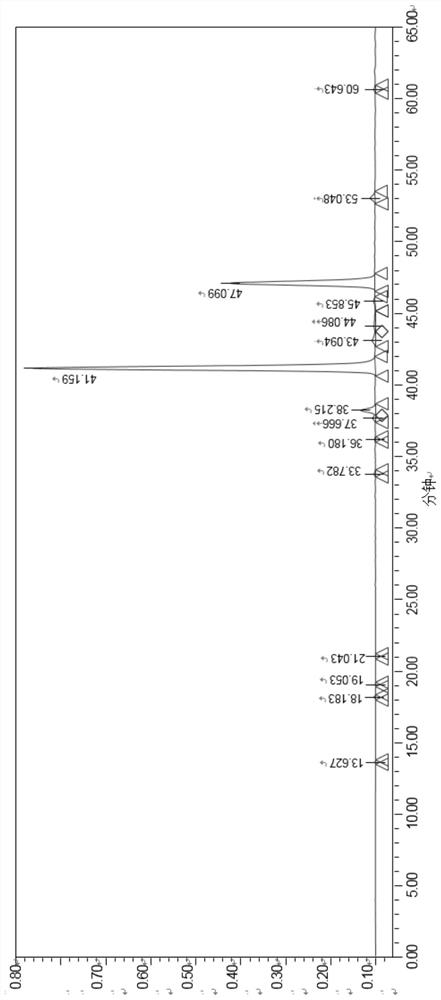

Embodiment 1

[0050] (1) Stevia leaf extraction:

[0051] Stevia leaves were extracted according to the ratio of water to dry leaves of stevia leaves at 20BV, the extraction temperature was 50°C, the extraction time was 3h, and the water extract of stevia leaves was obtained by filtration;

[0052] (2) Composite chitosan flocculation

[0053] After the stevia leaf water extract is adjusted to pH4.5 with the acetic acid aqueous solution of 1mol / L, add 1% composite chitosan acetic acid aqueous solution (quaternary ammonium salt chitosan accounts for 10% of composite chitosan quality, surplus is shell Polycan; the molecular weight of chitosan is 100KDa, and the degree of deacetylation is 80%), and the addition amount is 0.15mL per gram of dry leaves. At 20°C, stir at 30 rpm for 5 minutes, and let stand for 40 minutes to flocculate and remove impurities; then, separate the flocculation supernatant through plate and frame filtration; detect and calculate the retention rate of steviol glycosides...

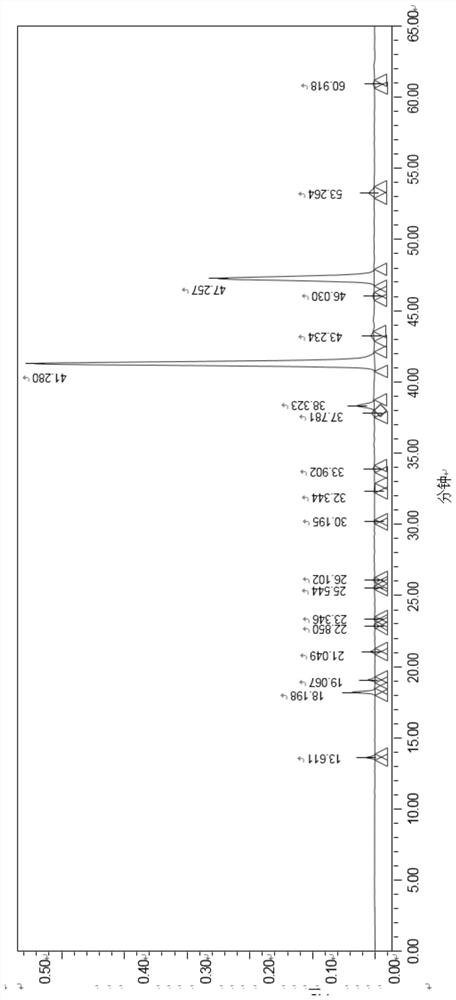

Embodiment 2

[0071] (1) Stevia leaf extraction:

[0072] Stevia leaves were extracted according to the ratio of water to dry stevia leaves of 15BV, the extraction temperature was 60°C, the extraction time was 3h, and the water extract of stevia leaves was obtained by filtration;

[0073] (2) Composite chitosan flocculation:

[0074] After the stevia leaf water extract is adjusted to pH5 with the acetic acid aqueous solution of 1mol / L, add 1% composite chitosan acetic acid aqueous solution (quaternary ammonium salt chitosan accounts for 15% of composite chitosan quality, surplus is chitosan ; the molecular weight of chitosan is 50KDa, the deacetylation degree is 70%), and the addition amount is 0.1mL per gram of dry leaves; at 40°C, stir at 30rpm for 5min, and let stand for 35min to flocculate and remove impurities; then, separate through plate and frame filtration The flocculation supernatant was obtained; the retention rate of steviol glycosides after flocculation was detected and calculat...

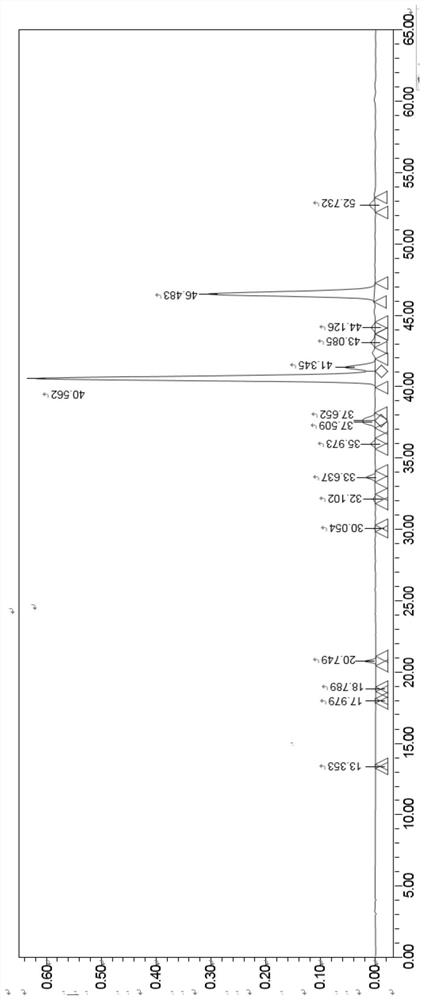

Embodiment 3

[0078] (1) Stevia leaf extraction:

[0079] The stevia leaves were extracted according to the ratio of water to dry stevia leaves of 20BV, the extraction temperature was 60°C, the extraction time was 3h, and the water extract of stevia leaves was obtained by filtration;

[0080] (2) Composite chitosan flocculation:

[0081] After the stevia leaf water extract is adjusted to pH4.5 with the acetic acid aqueous solution of 1mol / L, add 1% composite chitosan acetic acid aqueous solution (quaternary ammonium salt chitosan accounts for 15% of composite chitosan quality, surplus is shell Polycan; Chitosan molecular weight is 80KDa, deacetylation degree is 80%), the addition amount is 0.12mL per gram of dry leaves; Stir at 30rpm for 5min at 40°C, let stand for 50min to flocculate and remove impurities; then, through the plate frame The flocculation supernatant was obtained by filtration and separation; the retention rate of steviol glycosides after flocculation was detected and calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com