Fusion device for yellow lead production

A melting device and huangdan technology, which is applied in the direction of making medicines into special physical or taking forms of devices, etc., can solve the problems of affecting the reuse of the melting device, unable to discharge huangdan well, and slow efficiency, etc. The effect of heat utilization, avoiding direct heating, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

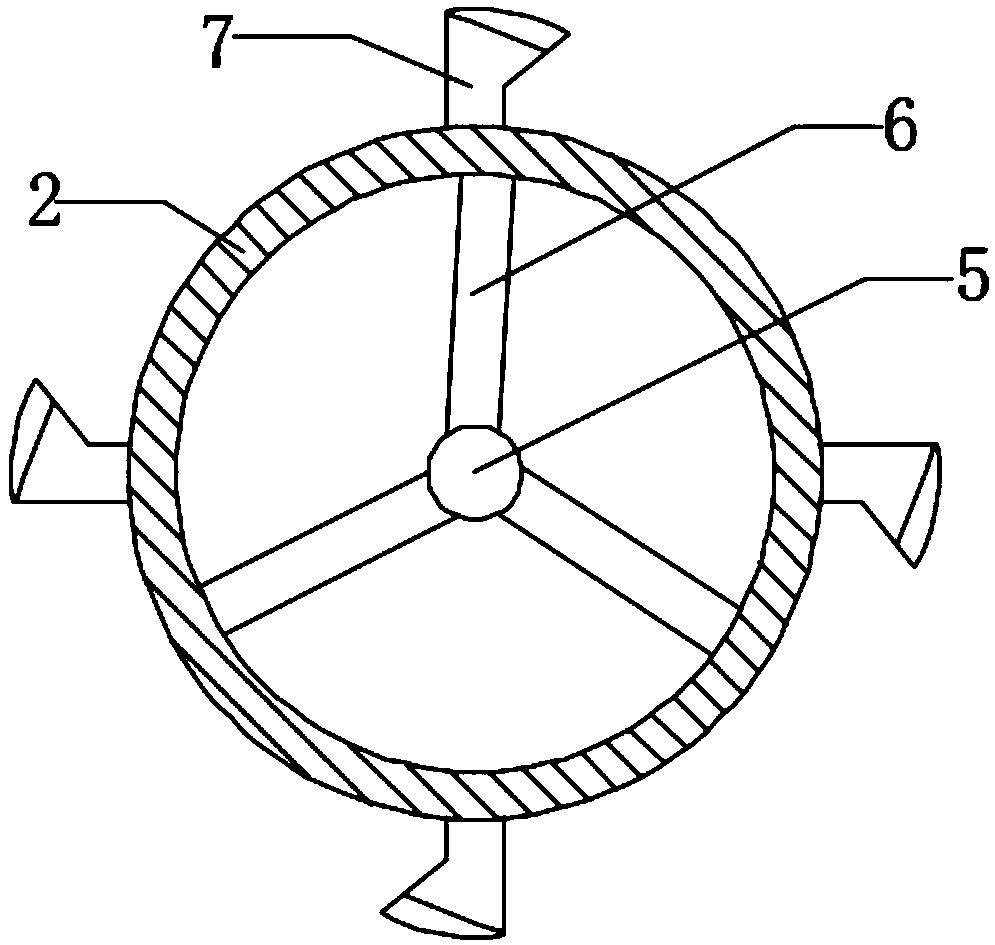

[0017] see Figure 1-2 , the present embodiment provides a melting device for the production of yellow dandelion, comprising a melting tank 1, a rotating drum 2 is rotatably connected inside the melting tank 1, a feeding port 3 is provided on the right side of the upper end of the melting tank 1, and the middle part of the upper end of the melting tank 1 is fixed A motor 4 is installed, the output shaft of the motor 4 is fixedly connected with a rotating shaft 5, and the side of the rotating shaft 5 is fixedly connected with several fixed rods 6, the rotating shaft 5 is fixedly connected with the inside of the rotating cylinder 2 through the fixed rods 6, and the side of the rotating cylinder 2 is fixedly connected There are several side wall shovels 7, and several bottom shovels 8 are fixedly connected to the lower end of the side of the rotating cylinder 2. The bottom of the melting tank 1 is fixedly connected to a fixed column 9, and the fixed column 9 is rotationally connec...

Embodiment 2

[0020] see Figure 1-2 , made further improvement on the basis of embodiment 1: heat preservation bucket 11 is to adopt glass fiber reinforced plastics composite plate to make, and this material has better heat preservation and heat-resistant performance, and rotating drum 2 sides are fixedly connected with eight side wall shovel plates 7. The structure is reasonable, it is convenient to realize the function of stirring and shoveling, and to ensure the cleanliness of the melting tank 1. The lower end of the side of the rotating cylinder 2 is fixedly connected with four bottom shovel plates 8, which is convenient for discharging. The side of the feeding port 3 is connected by rotation There is a cover, which can prevent the yellow dan from flying away when stirring and melting, and the lower end of the insulation barrel 11 is fixedly equipped with a runner, which is reasonable in structure and convenient to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com