Method for preparing low-hexachlorobenzene content chlorothalonil suspension

A chlorothalonil suspending agent and hexachlorobenzene technology, applied in the directions of botanical equipment and methods, fungicides, biocides, etc., can solve the problems of expensive raw materials, poor economic benefits, and reduction, and achieve good application prospects and reduce The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

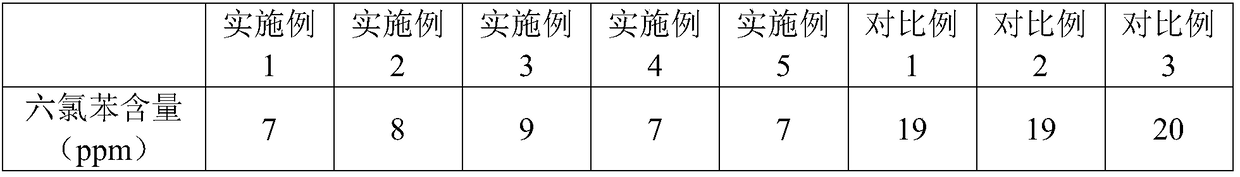

Examples

Embodiment 1

[0054] This embodiment provides a method for preparing a low-hexachlorobenzene-content chlorothalonil suspension. In terms of mass percentage, the low-hexachlorobenzene chlorothalonil suspension is composed of the following raw materials: chlorothalonil 40% , dipotassium hydrogen phosphate and bentonite 1%, sodium dodecylbenzenesulfonate 1%, fatty alcohol polyoxyethylene ether Pingpinga O-10 2%, sodium dodecylbenzenesulfonate 3%, xanthan gum 0.2 %, 0.5% triisobutyl phosphate, 0.2% Cathone, 5% propylene glycol, and the balance is water.

[0055] Prepare as follows:

[0056] (1) Add chlorothalonil, dipotassium hydrogen phosphate, bentonite, sodium dodecylbenzene sulfonate, fatty alcohol polyoxyethylene ether, O-10, sodium dodecylbenzene sulfonate and triisophosphate according to the formula amount Butyl ester is mixed with water, and ground until the particle size of the material is 0.5-5 μm to obtain a mixed slurry, wherein the addition of triisobutyl phosphate is 35% of the t...

Embodiment 2

[0060] This embodiment provides a method for preparing a low-hexachlorobenzene-content chlorothalonil suspension. In terms of mass percentage, the low-hexachlorobenzene chlorothalonil suspension is composed of the following raw materials: chlorothalonil 40% , bentonite 1%, sodium lignosulfonate 1%, mixture of alkylnaphthalene sulfonate and anionic wetting agent Morwet EFW 2.5%, phenethylphenol ethoxylate 2.5%, polyacrylamide 0.2%, phosphoric acid Tributyl 0.5%, sodium benzoate 0.2%, propylene glycol 5%, and the balance is water.

[0061] Prepare as follows:

[0062] (1) Mix chlorothalonil, bentonite, sodium lignosulfonate, alkylnaphthalene sulfonate and anionic wetting agent Morwet EFW, phenethylphenol polyoxyethylene ether, triisobutyl phosphate and water according to the formula quantity Mixing and grinding until the particle size of the material is 0.5-5 μm to obtain a mixed slurry, wherein the added amount of triisobutyl phosphate is 45% of the total amount, and the added...

Embodiment 3

[0066] This embodiment provides a method for preparing a low-hexachlorobenzene-content chlorothalonil suspension. In terms of mass percentage, the low-hexachlorobenzene chlorothalonil suspension is composed of the following raw materials: 50% chlorothalonil , white carbon black 1%, alkyl naphthalene sulfonate formaldehyde condensate Morwet D425 1%, alkylphenol polyoxyethylene ether OP-7 2%, magnesium aluminum silicate 0.5%, ethyl silicone oil 0.5%, propylene glycol 5% , POM 0.2%, the balance is water.

[0067] Prepare as follows:

[0068] (1) Mix chlorothalonil, white carbon black, alkylnaphthalene sulfonate formaldehyde condensate Morwet D425, alkylphenol polyoxyethylene ether OP-7, ethyl silicone oil and water according to the formula, and grind to the particle size of the material 0.5-5 μm to obtain a mixed slurry, wherein the amount of ethyl silicone oil added is 35% of the total amount, and the amount of water added is 65% of the total amount of water;

[0069] (2) Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com