Rigid-flexible printed circuit board and manufacturing method thereof

A technology of soft-rigid combination board and production method, which is applied in the direction of multi-layer circuit manufacturing, printed circuit manufacturing, conductive pattern layout details, etc., can solve the problems of residual glue risk of protective tape, difficulty in laminating, difficulty in opening cover, etc., and achieve saving Adhesive barrier film bonding process, improving the efficiency of opening the cover, and increasing the effect of wiring density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0054] see Figure 1-7, the first embodiment of the present invention provides a method for manufacturing a rigid-flex board 100, which includes the steps of:

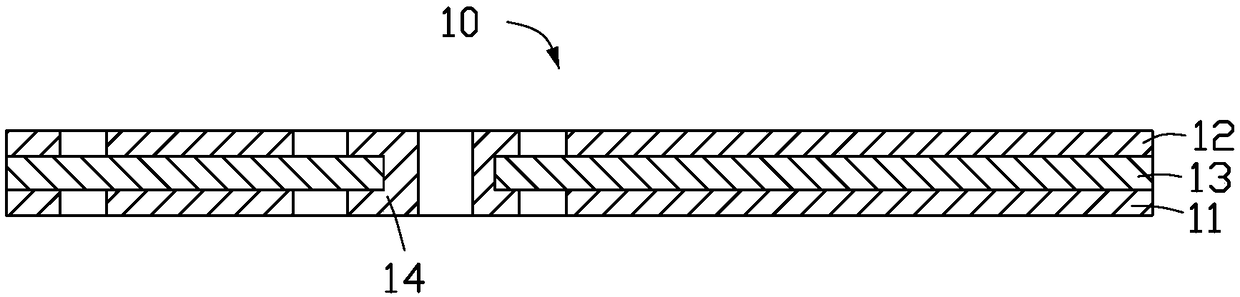

[0055] For a first step, see figure 1 , providing a flexible circuit board 10, the flexible circuit board may be a single-sided circuit board, a double-sided circuit board or a multi-layer board. In this embodiment, a double-sided circuit board is taken as an example for description.

[0056] The flexible circuit board 10 includes a flexible board substrate 13 , a first conductive circuit layer 11 , a second conductive circuit layer 12 and a first conductive hole 14 located on opposite surfaces of the flexible board substrate 13 . The second conductive circuit layer 12 is electrically connected to the first conductive circuit layer 11 through the first conductive hole 14 .

[0057] The number of the first conductive hole 14 may be multiple, or only one. The first conductive hole 14 can be a conductive via hole that...

no. 2 example

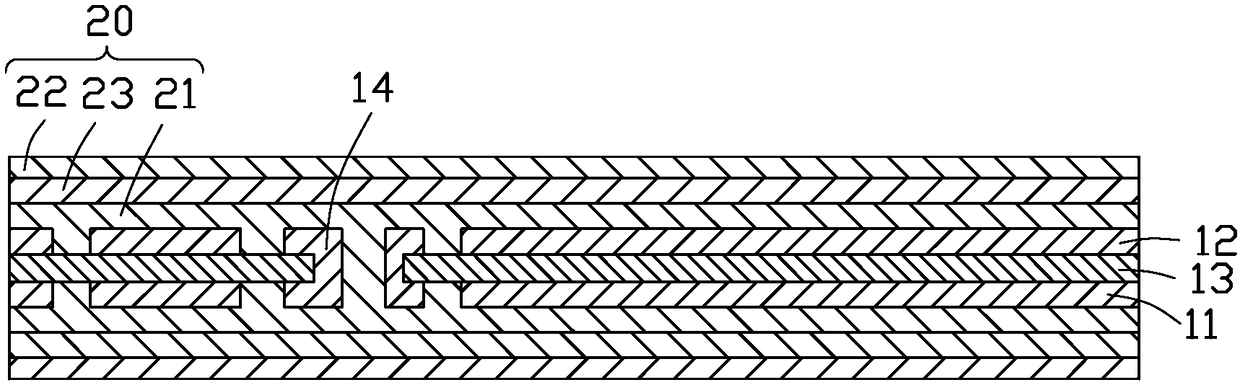

[0068] see Figure 8-12 The first step to the third step of the manufacturing method of the rigid-flex board provided by the second embodiment are the same as the first step to the third step of the manufacturing method of the rigid-flex board provided by the first embodiment. The reason is that in this embodiment, the step of opening the window has been completed before the surface build-up of the first double-sided adhesive film and the second double-sided adhesive film, that is, there is no need to etch away the first double-sided adhesive film after pressing. The first copper foil 41 and the second copper foil 42 at the positions of the opening 301a and the second opening 301b. The fourth step in this embodiment is specifically as follows:

[0069] Step four, see Figure 8 , providing two copper-clad substrates 60, the copper-clad substrate 60 includes a dielectric layer 30 and a copper foil 40 formed on at least one surface of the dielectric layer 30; please refer to ...

no. 3 example

[0072] see again Figure 7 , the third embodiment of the present invention provides a rigid-flex board 100, which includes: a flexible circuit board 10, a first double-sided adhesive film 20a located on one surface of the flexible circuit board 10, a first double-sided adhesive film 20a located on the first double-sided The first dielectric layer 31 on the surface of the adhesive film 20a, the first outer conductive circuit layer 410 located on the surface of the first dielectric layer 31; the second double-sided adhesive film 20b located on the other surface of the flexible circuit board 10, located on the second The second dielectric layer 32 on the surface of the double-sided adhesive film 20b, the second outer conductive circuit layer 420 on the second dielectric layer 32 surface, and the first outer conductive circuit layer 410 and the second outer conductive circuit layer respectively The solder resist layer 53 on the surface of 420.

[0073] The flexible circuit board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com