Selenium yeast hydrolyzate and its preparation method and application

A technology of selenium yeast and hydrolyzate, which is applied in the production of yeast selenium and the field of biological enzymolysis, which can solve the problems of large environmental impact and reduced product yield, and achieve the effects of high content of functional ingredients, increased absorption rate, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

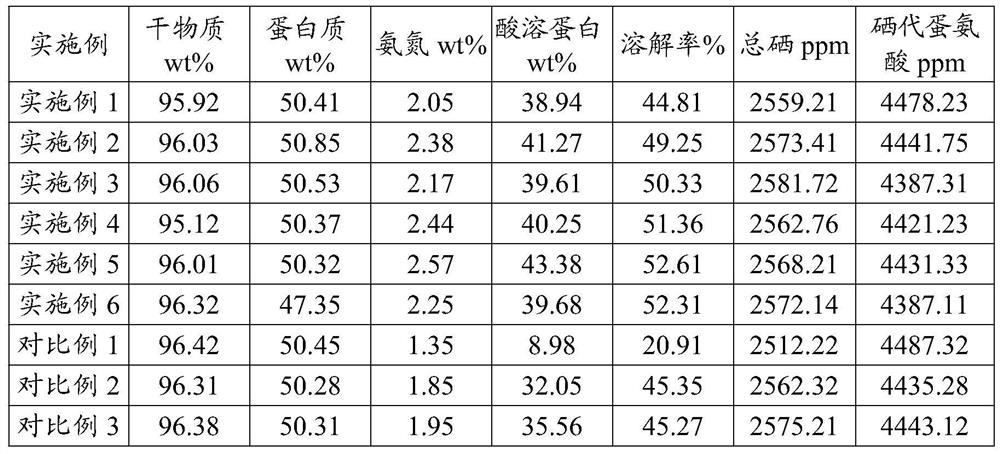

Examples

preparation example Construction

[0045] The preferred preparation method of selenium yeast hydrolyzate in the present invention comprises the following steps:

[0046] (1) The selenium yeast milk is stored at 2-8° C., and the pH of the selenium yeast milk is adjusted to 4-5, preferably 4.5-4.8 by adding 2%-6% citric acid relative to the weight of yeast dry matter.

[0047]If the amount of citric acid is too high, the content of crude protein, ammonia nitrogen, and acid-soluble protein will decrease. At the same time, the addition of excessive citric acid will increase the amount of sodium hydroxide, which will also indirectly reduce crude protein, acid-soluble protein, and ammonia nitrogen. In the present invention, it is preferable to add citric acid accounting for 3-4% of the weight of yeast dry matter. The amount of citric acid added within this range can reduce the risk of microbial contamination during material transfer and heating, and can promote some functional indicators of the product.

[0048] (2) ...

Embodiment 1

[0067] (1) Store the separated selenium yeast milk at 3-4° C., and add 2% citric acid to adjust the pH to 4.9-5.0.

[0068] (2) Rapidly heat up the selenium yeast preserved in step (1) by means of short-term heat exchange with 93-95°C steam, heat up to 37.5-39.5°C for 1 hour; heat up to 46.5-48.5°C for 1 hour, then heat up to 51.5-53.5°C.

[0069] (3) Keep the temperature of the yeast milk heated up in step (2) at 51.5-53.5° C., and keep it warm for 6 hours.

[0070] (4) Adjust the pH of the yeast milk after step (3) for 6 hours to 5.6-5.7, heat up to 55.5-57.5°C, then add 0.13% papain, 0.13% neutral protease, and 0.13% alkaline protease to carry out enzymatic hydrolysis reaction 10h.

[0071] (5) Heating the hydrolyzate obtained in step (4), incubating at 73-75° C. for 1 h, evaporating and concentrating to a solid content of 40%, and spray-drying to obtain the selenium yeast hydrolyzate.

[0072] The spray drying conditions are: the inlet air temperature is controlled at 1...

Embodiment 2

[0074] (1) Store the separated selenium yeast milk at 2-3°C, and add 3% citric acid to adjust the pH to 4.7-4.8.

[0075] (2) Rapidly raise the temperature of the selenium yeast preserved in step (1) by means of short-term heat exchange with steam at 90-92°C, raise the temperature to 35.5-37.5°C, and keep it warm for 1.5h; heat it up to 45.5-47.5°C and keep it warm for 1.5h , and then heated to 53.5-55.5 ° C.

[0076] (3) Keep the temperature of the yeast milk heated up in step (2) at 53.5-55.5° C., and keep it warm for 10 hours.

[0077] (4) Adjust the pH of the autolyzed yeast milk in step (3) to 6.1-6.2, raise the temperature to 57.5-59.5°C, and then add 0.3% papain, 0.3% alkaline protease and 0.3% flavor protease to carry out the enzymatic hydrolysis reaction for 6 hours .

[0078] (5) Heating the hydrolyzate obtained in step (5) to 70-72° C., keeping it warm for 2 hours, evaporating and concentrating to a solid content of 37%, and spray-drying to obtain the selenium yea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com