Shielded wire for high voltage skin effect trace heating

A skin effect and voltage technology, applied in ohmic resistance heating, ohmic resistance heating parts, electric heating devices, etc., can solve the problems of insulation device breakdown, corrosion of solid insulation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

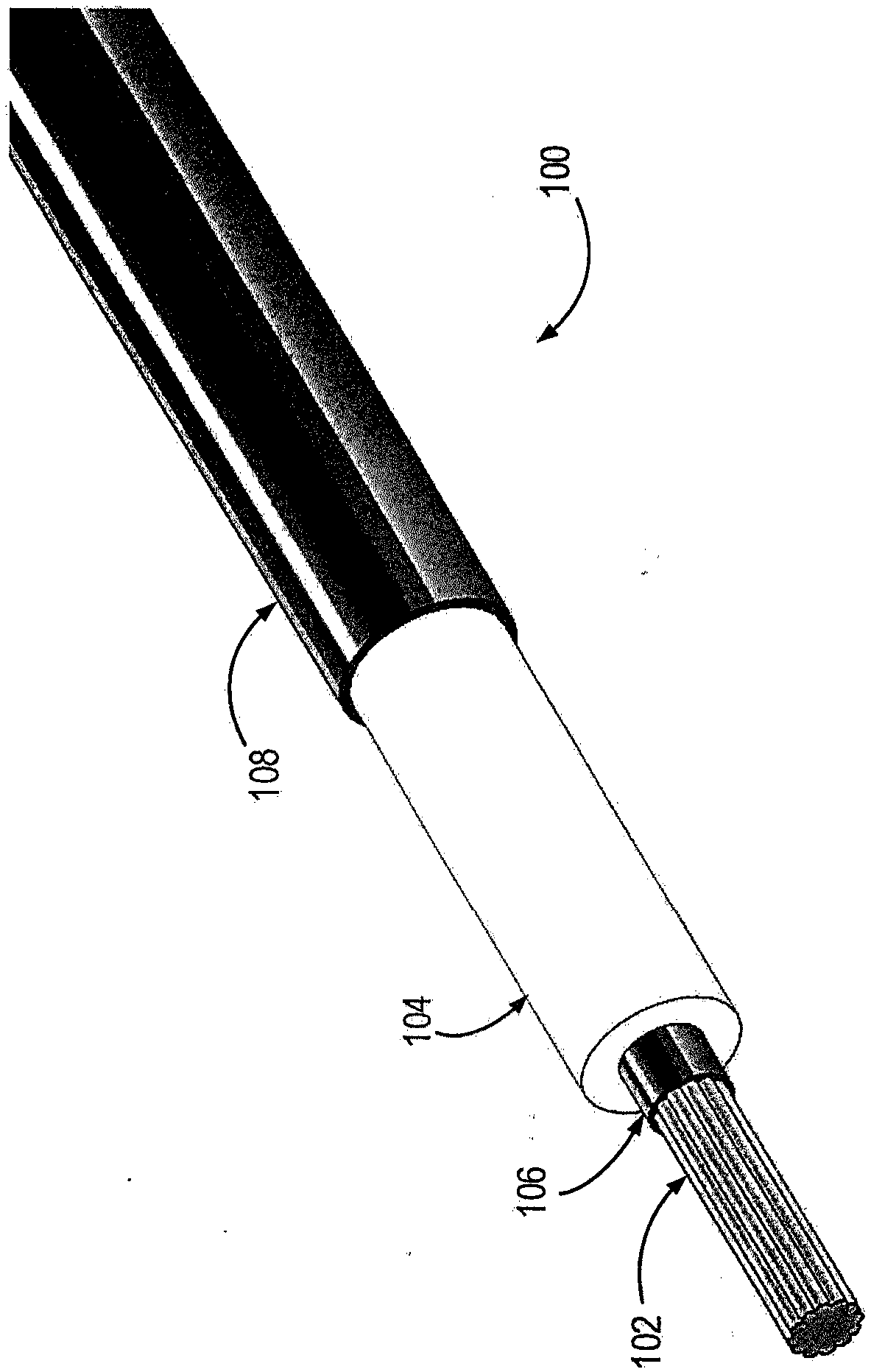

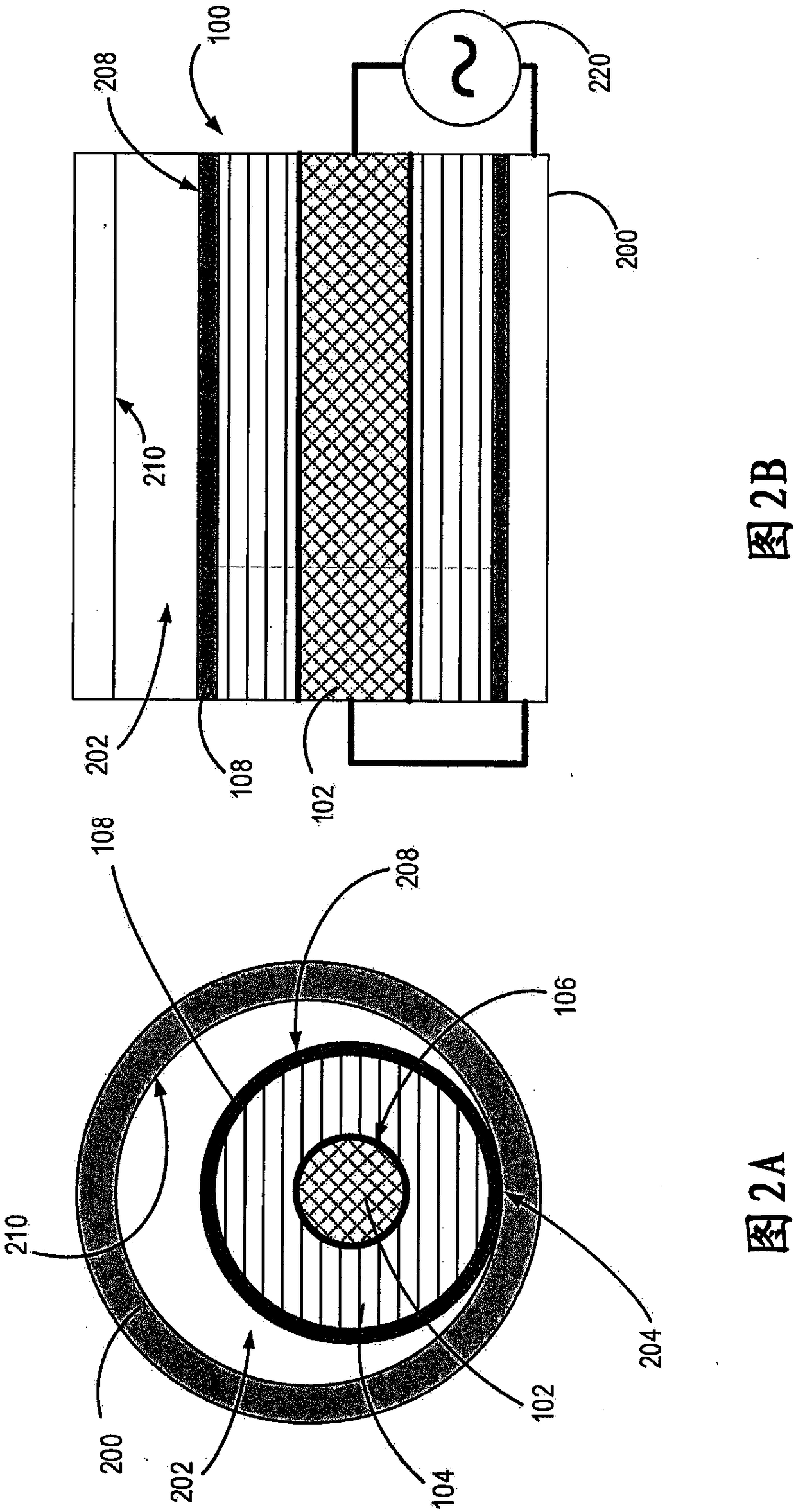

[0020] Referring now to the figure, figure 1 A heating cable 100 is shown according to various embodiments. The illustrated heating cable 100 is shown with each layer subsequently stripped away to clearly illustrate its construction in accordance with at least one embodiment. The heating cable 100 comprises a conductor 102 at its core. Conductor 102 may be any suitable conductive material, including tin-plated copper, nickel-plated copper, aluminum, steel, gold, platinum, silver, and others. The conductor 102 may be a solid wire or may be a stranded wire. Conductor 102 is encapsulated within an electrically insulating layer 104 that is not conductive. Electrically insulating layer 104 may be any suitable material, including silicone, PFA, EDPM, XPLE, and others. In some embodiments, the periphery of conductor 102 physically contacts electrically insulating layer 104 entirely. In other embodiments, the conductor 102 is encapsulated within the inner semiconducting layer 106...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com