Friction nanometer power generator for converting mechanical energy to electric energy and fabrication method of friction nanometer power generator

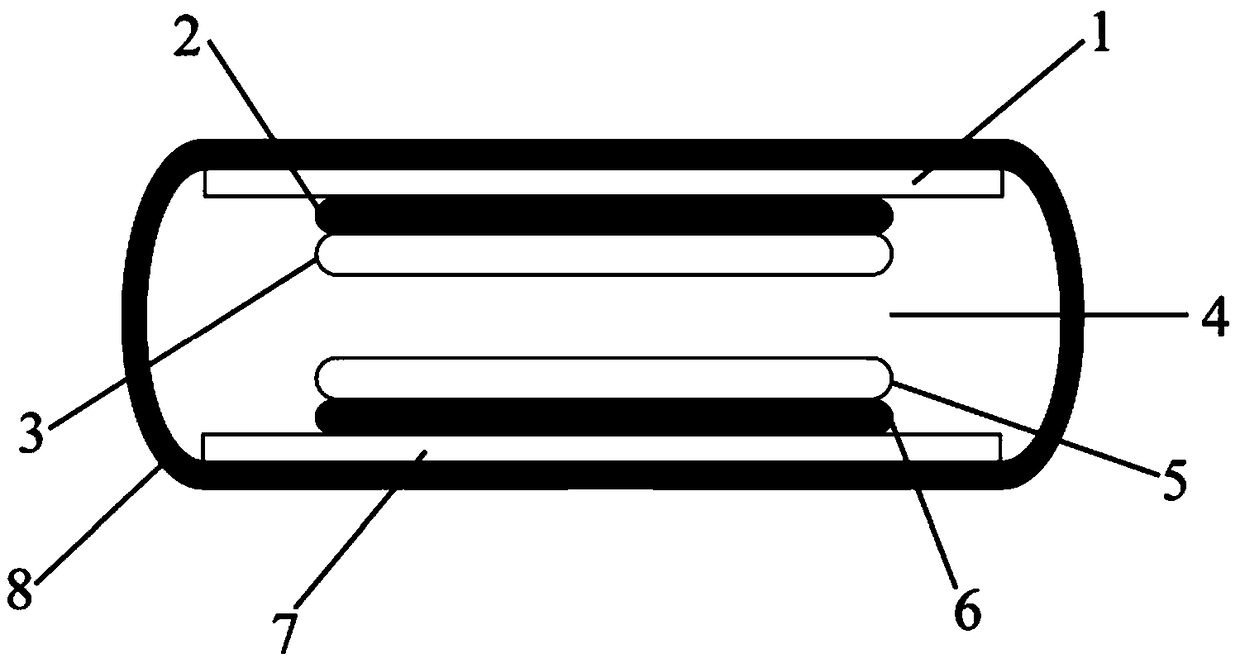

A nano-generator and mechanical energy technology, applied in the direction of friction generators, etc., to achieve the effects of improving compatibility, improving electrical output performance, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

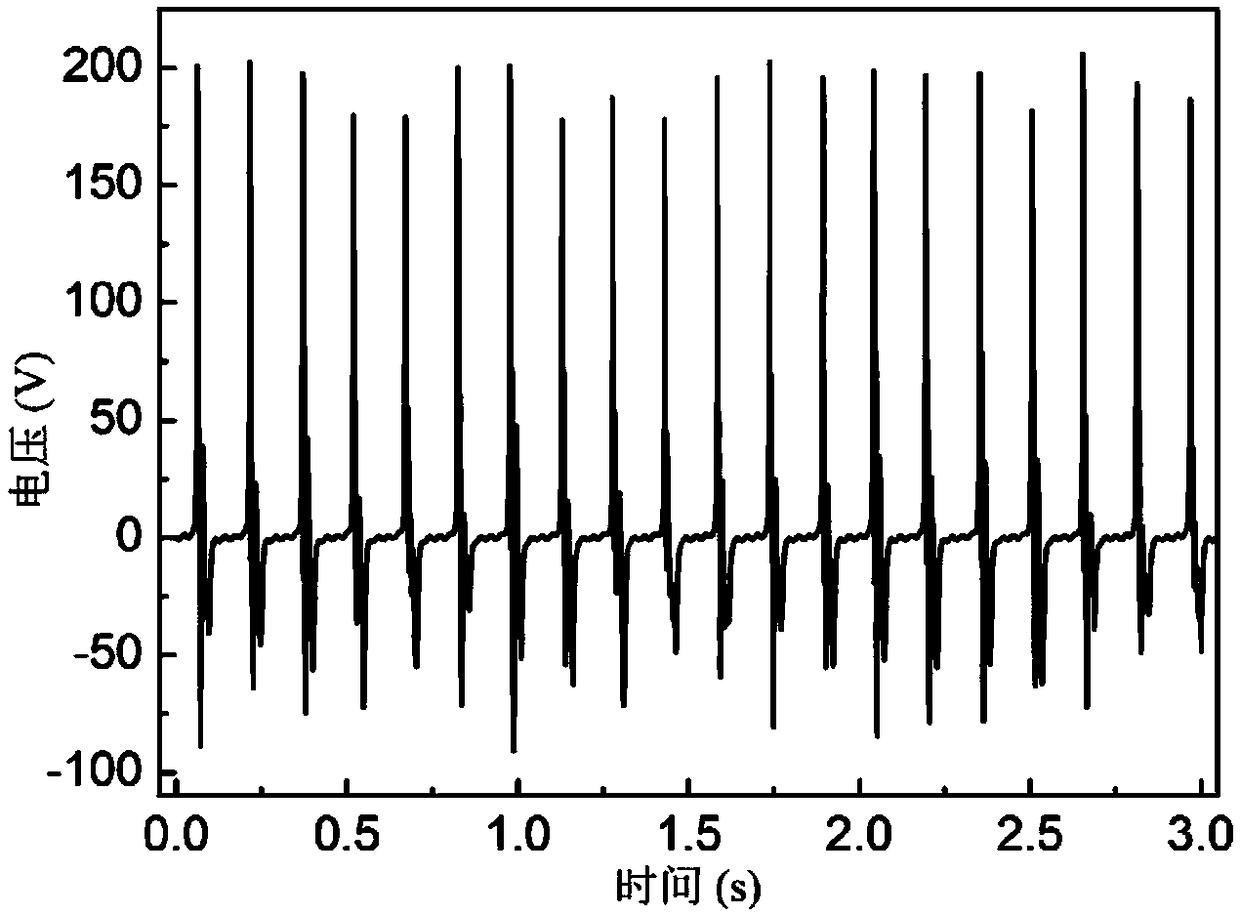

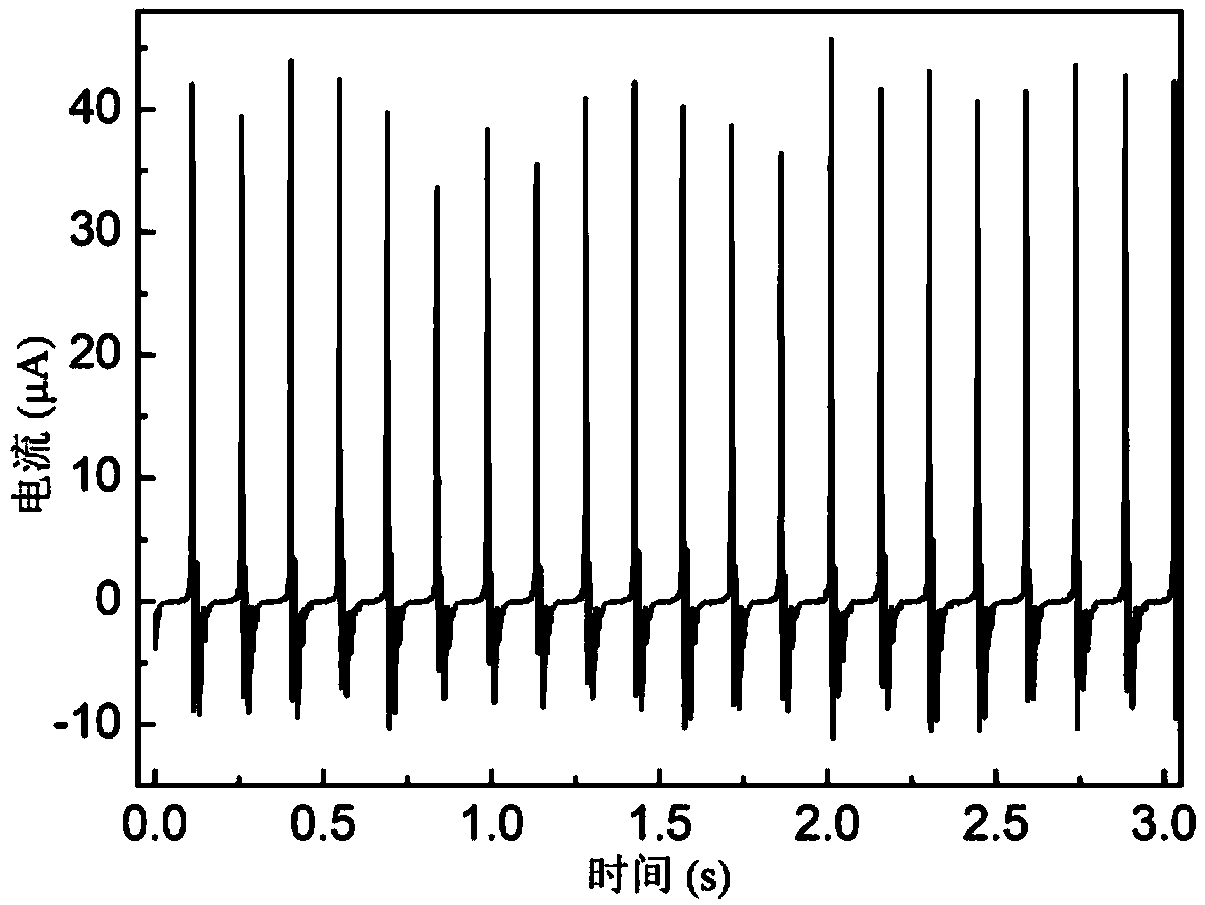

Examples

Embodiment 1

[0049] A method for preparing a triboelectric nanogenerator for converting mechanical energy into electrical energy, the specific steps are:

[0050] (1) preparing an electronegative friction layer;

[0051] (1.1) Disperse 0.2 g of nanofibers with a diameter of 150 to 300 nm in a mixture (mass ratio of 4:1) of 1 wt % acetic acid and tert-butanol at a speed of 8000 rpm to obtain a concentration of 0.5 wt % Then add 350 μL of cross-linking agent glutaraldehyde and stir at high speed for 5 minutes (the purpose of adding cross-linking agent glutaraldehyde is to prevent the airgel structure from collapsing easily when it collides), wherein the nanofibers are ethylene-vinyl alcohol The copolymer is prepared by uniformly mixing ethylene-vinyl alcohol copolymer and cellulose acetate butyrate, and adopting a two-component incompatible system melt blending phase separation method;

[0052] (1.2) After freezing the nanofiber suspension in a low-temperature refrigerator at -50°C for 20h,...

Embodiment 2

[0119] The method for preparing a triboelectric nanogenerator for converting mechanical energy into electrical energy, the specific steps are basically the same as in Example 1, the difference is that the electronegative friction layer and the electropositive friction layer are prepared by chemical modification, and the specific steps are as follows :

[0120] (1) preparing an electronegative friction layer;

[0121](1.1) Disperse nanofibers with a diameter of 150-300nm in a mixed solvent of water and tert-butanol (mass ratio 4:1), wherein the nanofibers are glycidyl methacrylate grafted polyethylene and acetate butyrate fiber After uniform mixing, it is prepared by melt blending phase separation method of two-component incompatible system;

[0122] (1.2) After adding polyterephthalic acid and epichlorohydrin, stir at a high speed at a speed of 13000 rpm to obtain a nanofiber suspension with a mass percentage concentration of 1.8%, wherein polyterephthalic acid is 20% of the ...

Embodiment 3

[0130] A method for preparing a triboelectric nanogenerator for converting mechanical energy into electrical energy, the specific steps are:

[0131] (1) preparing an electronegative friction layer;

[0132] (1.1) Disperse 0.2 g of nanofibers with a diameter of 250 to 380 nm in 20 wt % methanol and stir at a high speed at 11000 rpm to obtain a nanofiber suspension with a concentration of 2.2 wt %, then add 350 μL of crosslinking agent glutaraldehyde and stir at high speed 5 minutes, wherein the nanofibers are obtained by uniformly mixing polyamide 6 and cellulose acetate butyrate, and adopting a two-component incompatible system melt blending phase separation method;

[0133] (1.2) After freezing the nanofiber suspension in a low-temperature refrigerator at -60°C for 12h, freeze-drying at a temperature of -50°C for 48h to obtain the nanofiber airgel, the porosity of the nanofiber airgel is 98.5 %;

[0134] (1.3) Use a glass rod to immerse the surface of the airgel in a polyv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com