Shielding sheet with air gap and manufacturing method of shielding sheet

A manufacturing method and shielding sheet technology, which is applied in magnetic core manufacturing, inductor/transformer/magnet manufacturing, electrical components, etc., can solve problems such as uneven distribution of magnetic field, inability to fully exert the shielding effect of soft magnetic materials, and large thickness of shielding sheet , to achieve good shielding effect, improve anti-saturation ability, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

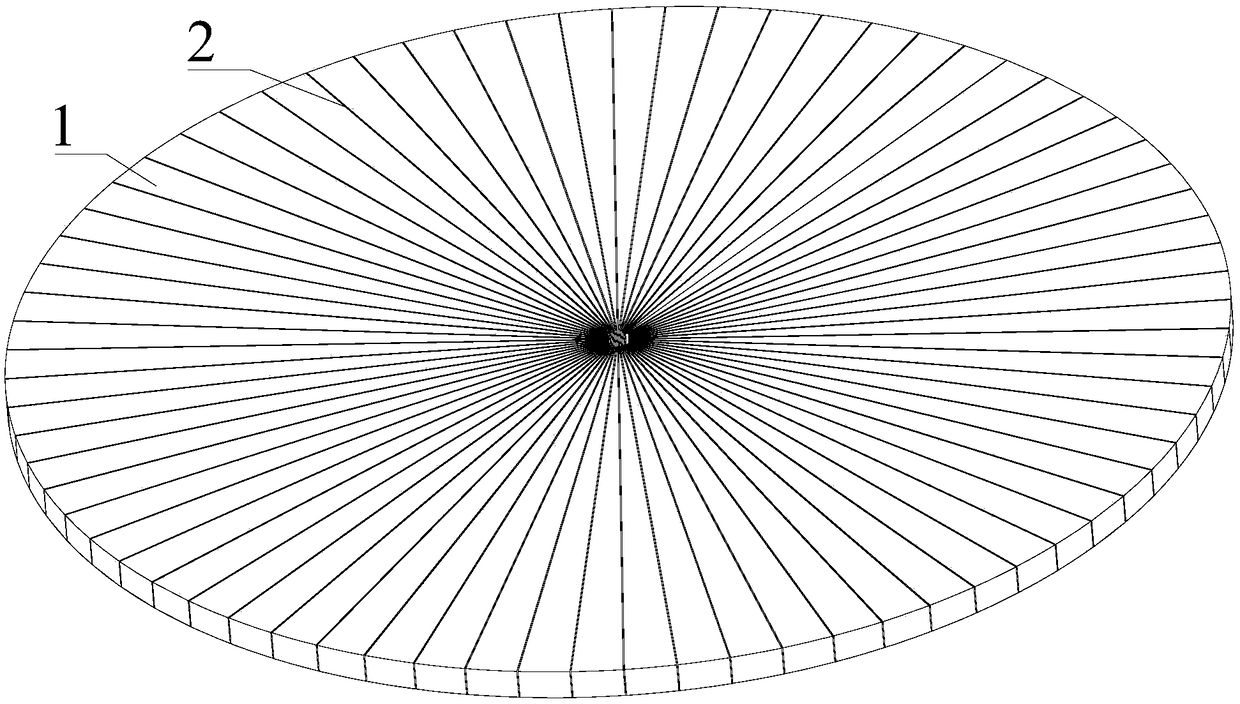

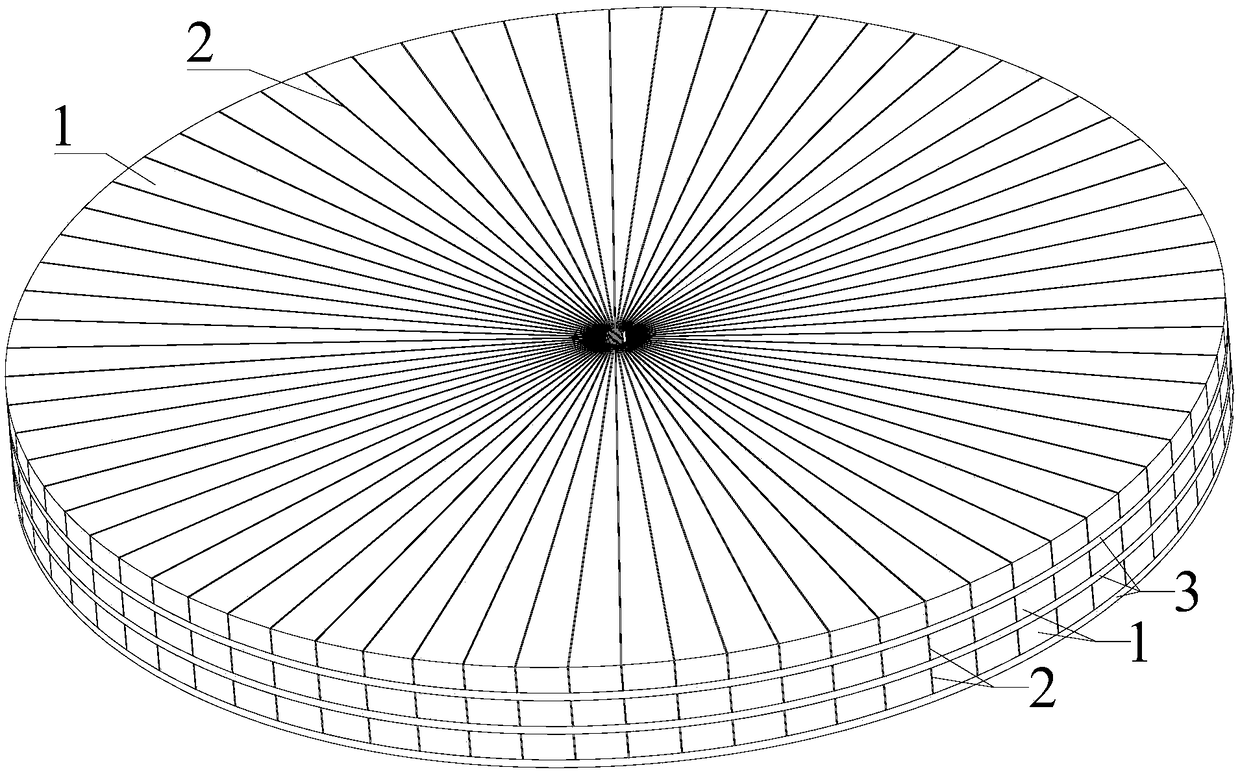

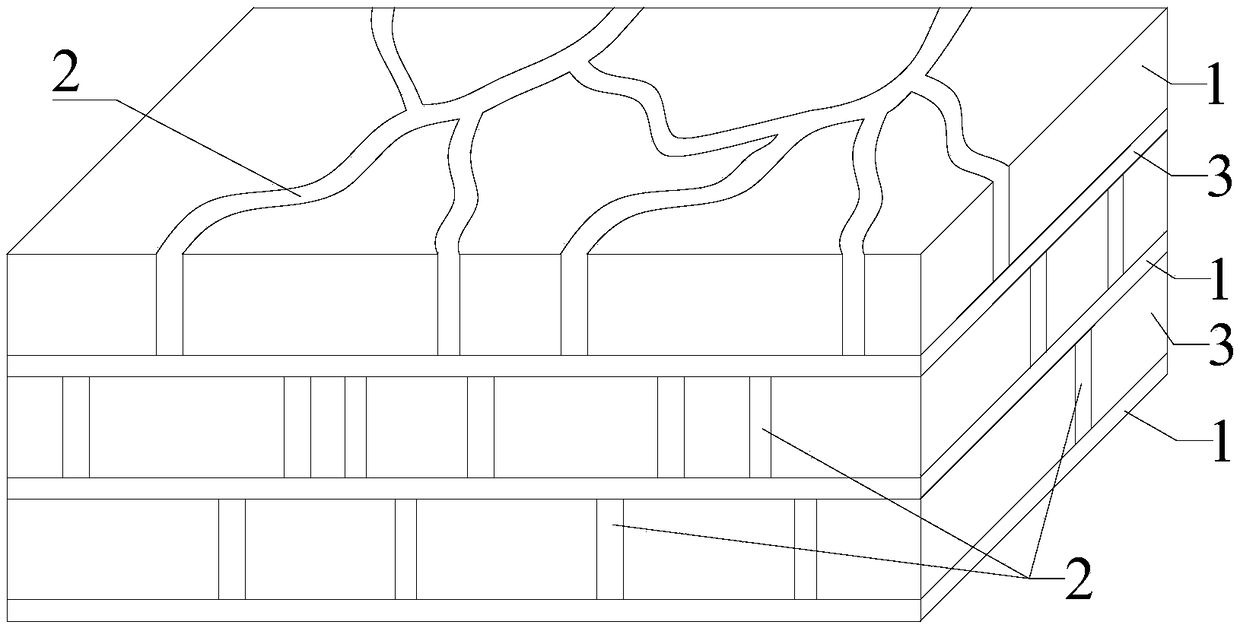

[0030] Please refer to figure 1 and figure 2 , Embodiment 1 of the present invention is: a shielding sheet with an air gap, including a magnetic sheet 1, an air gap structure 2 is arranged on the magnetic sheet 1, and the air gap structure 2 is radial. The total length of the air gap structure 2 corresponding to the unit area is adapted to the magnetic field strength distribution of the charging coil. In the region with a strong magnetic field, the total length of the air gap structure 2 corresponding to the region is long; in the region with a weak magnetic field, the corresponding air gap in the region Structure 2 has a short overall length. According to the theory of demagnetization field, the region where the total length of the air gap structure 2 is long has low magnetic permeability; the region where the total length of the air gap structure 2 is short has high magnetic permeability.

[0031] In this embodiment, the air gap structure 2 includes a plurality of cutouts...

Embodiment 2

[0037] Embodiment 2 of the present invention is: the manufacturing method of the shielding sheet with air gap, the alloy composition is Fe73.5Cu1Nb3Si15.5B7 (at.%), 60mm wide, 20 μ m thick nanocrystalline ribbons are wound into an inner diameter of 100mm, A ring-shaped iron core with an outer diameter of 120 mm is placed in a heat treatment device (such as an oven) and heat-treated at 550° C. for 1 hour under an argon protective atmosphere.

[0038] The heat-treated nanocrystalline iron core is coated, that is, a layer of 5 μm insulating glue 3 is pasted on one side of the magnetic sheet 1, and then the coated magnetic sheet 1 is laminated into a three-layer nanocrystalline structure to obtain a semi-finished product.

[0039] The radial air gap structure 2 is cut on the semi-finished product with a cutting device, and the outline of the semi-finished product is die-cut to make the outer periphery of the semi-finished product circular, and the ratio of the total length of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com