Width-adjustable acid rolling device capable of eliminating residual acid

A residual acid and rolling acid technology, applied in lead-acid battery electrodes, electrode rolling/calendering, electrode manufacturing, etc., can solve problems such as the influence of battery assembly, the increase of rechargeable batteries, and the surface cracks of the lead paste on the raw plate. Achieve the effect of improving battery quality, reducing frequent replacement and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

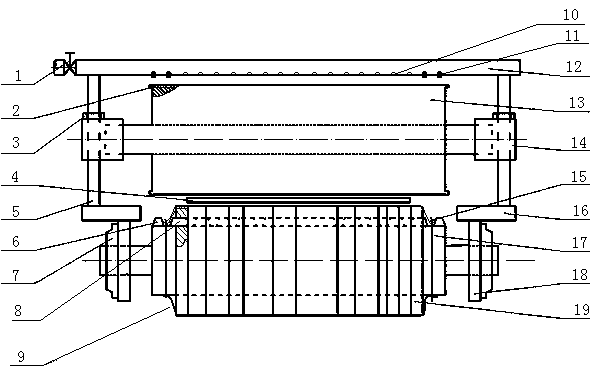

[0015] Such as figure 1 As shown, the present invention includes an upper rolling roller 13 and a lower rolling roller 9 with the green electrode plate 4 rolled through in the middle, and the outer surface of the upper and lower rolling rollers is covered with 4-6 layers of acid-resistant roller cloth 2. The top of the rolling roller 13 is provided with an acid-drenching straight pipe 12 arranged in parallel, and the front end of the acid-drenching straight pipe 12 is equipped with a solenoid valve connected with the acid delivery pipe, and the solenoid valve 1 is connected to the control cabinet of the smear machine in the previous process and connected with the smear. Machine linkage, a plurality of acid spray holes 10 are evenly spaced on the lower wall of the acid spray straight pipe 12, and according to the length of the raw plate to be rolled, the acid spray holes 10 at both ends are equipped with plugging tapered plastic strips 11 to reduce the difference in rolling. Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com