Lithium slurry battery, module and preparation method thereof

A slurry battery and battery cell technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery covers/end covers, etc., can solve problems such as unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described through embodiments below in conjunction with the accompanying drawings.

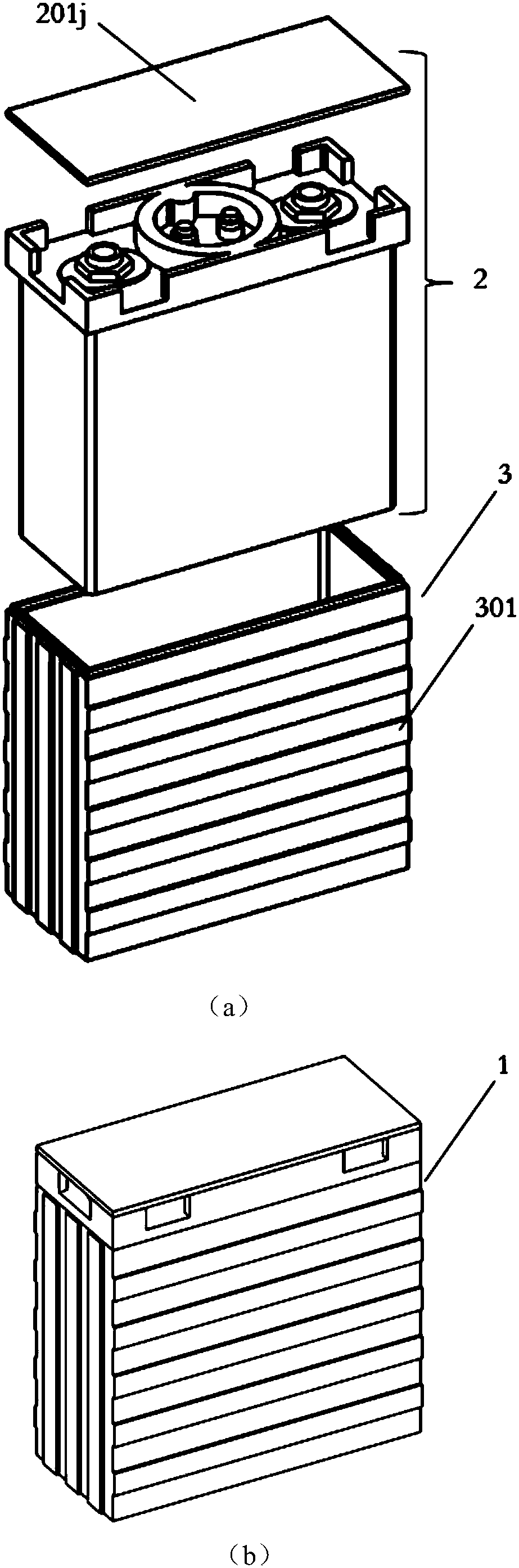

[0081] figure 1 It is (a) exploded view and (b) assembled view of the lithium slurry battery according to the present invention. The lithium slurry battery 1 includes a battery cell unit 2 and a single casing 3, and the battery cell unit 2 can be placed in the single casing 3 and sealedly connected thereto. A reinforcing rib 301 is provided on the single body casing 3 , and a cooling space for air circulation is formed between the reinforcing ribs.

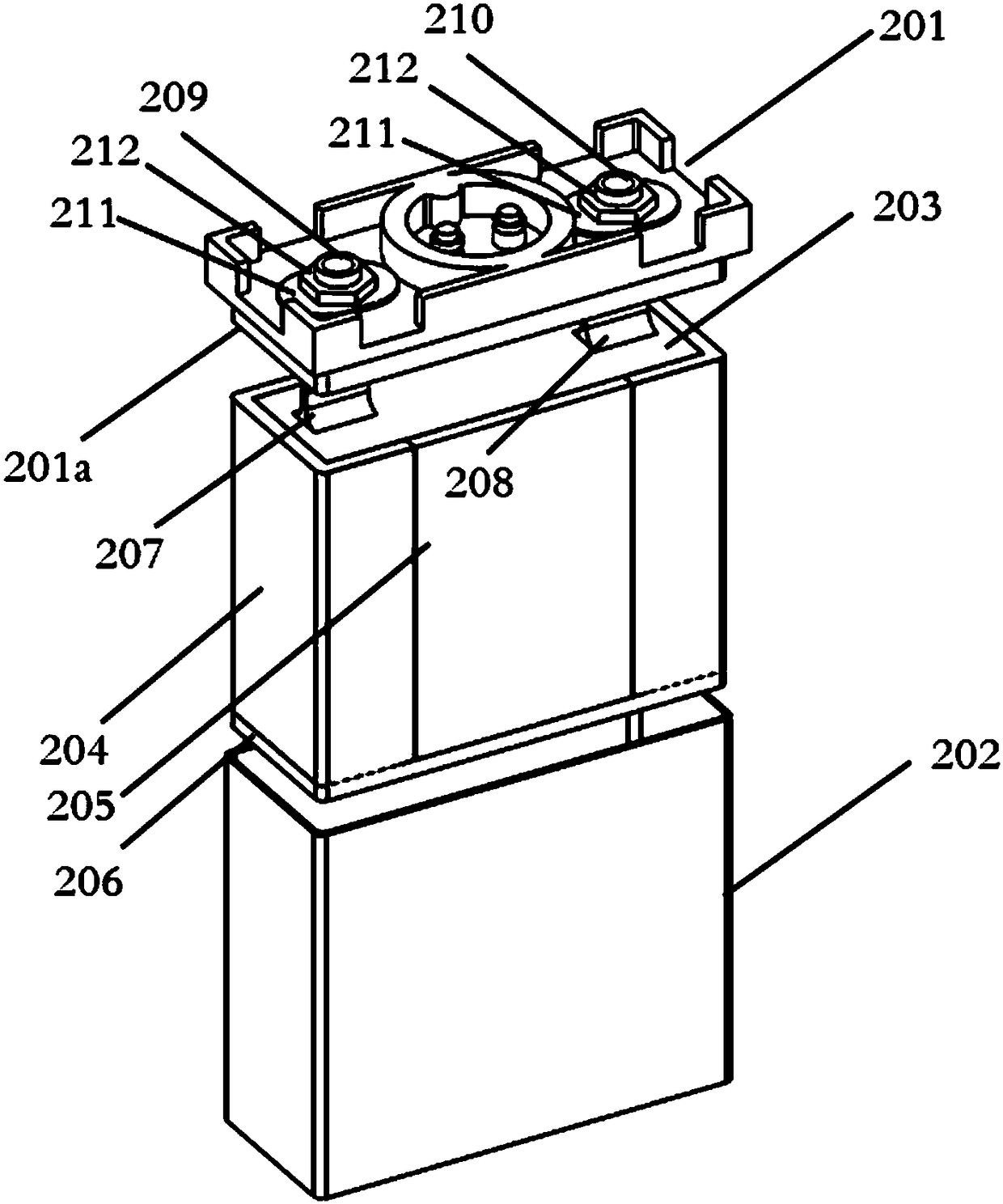

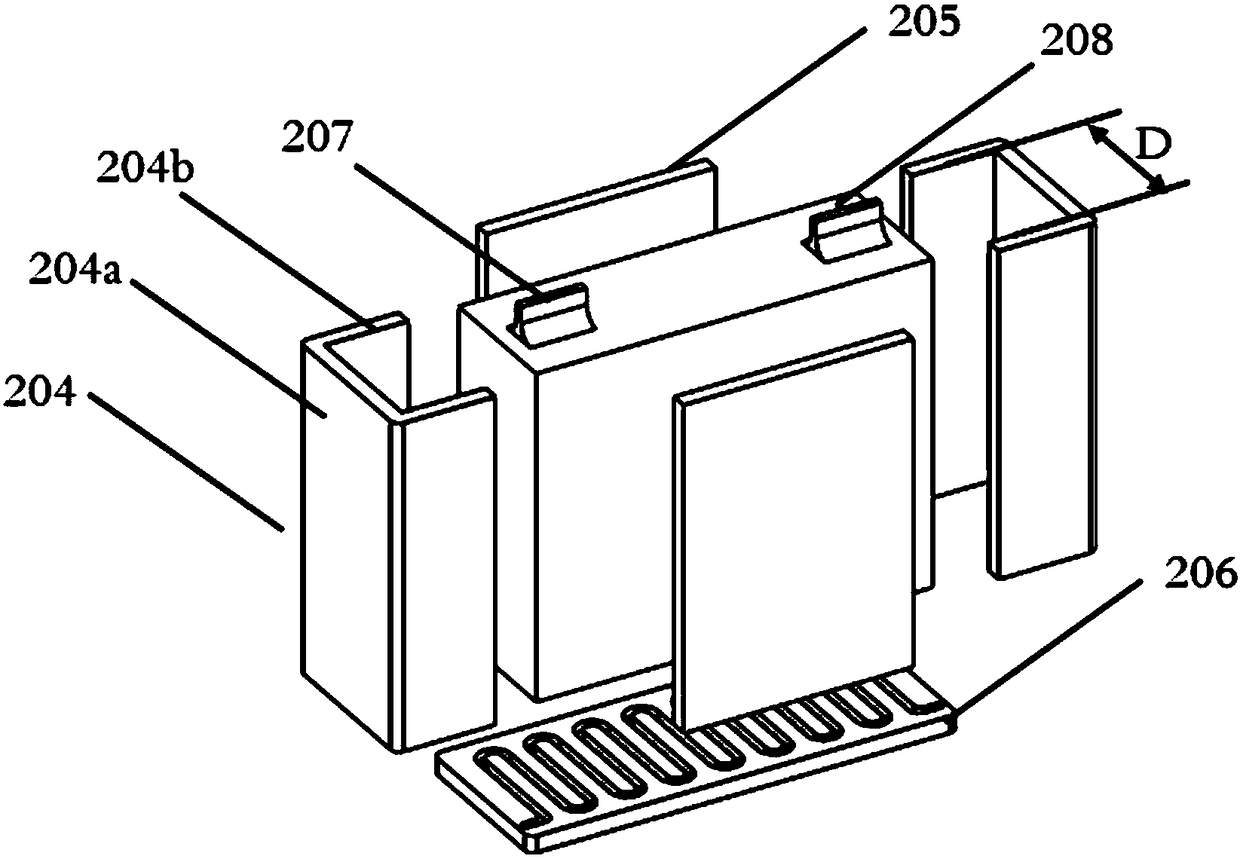

[0082] figure 2 It is an exploded view of the cell unit of the lithium slurry battery according to the present invention. The battery unit 2 includes a single case cover 201 , a battery bag 202 and a battery 203 . In addition, the holder 204 , the protective plate 205 and the groove plate 206 may also be disposed in the battery bag 202 around the battery cell 203 . After the battery cell 203 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com