Semiconductor device and forming method thereof

A semiconductor and device technology, applied in the field of semiconductor devices and their formation, can solve problems such as poor performance of semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] As mentioned in the background, semiconductor devices formed in the prior art have poor performance.

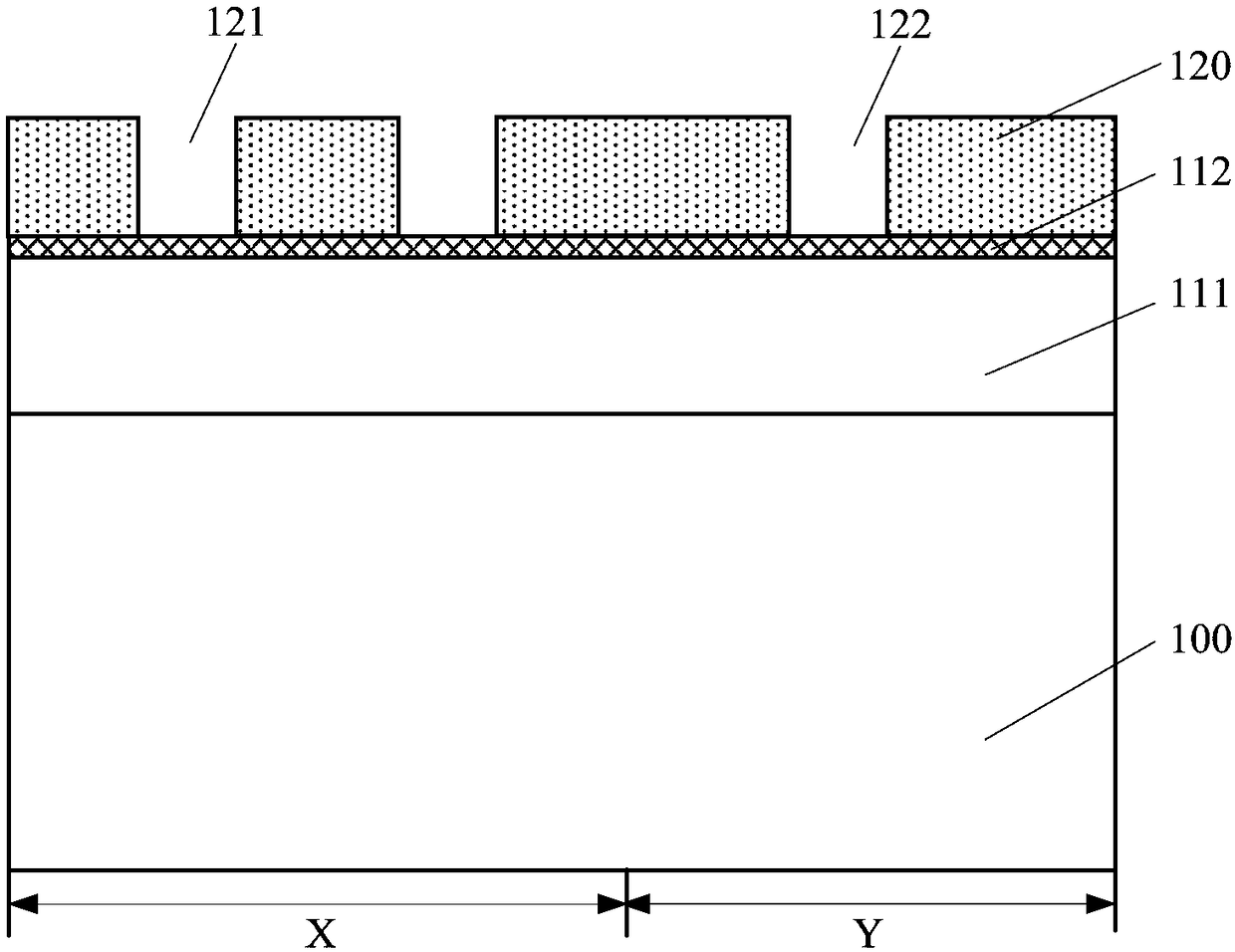

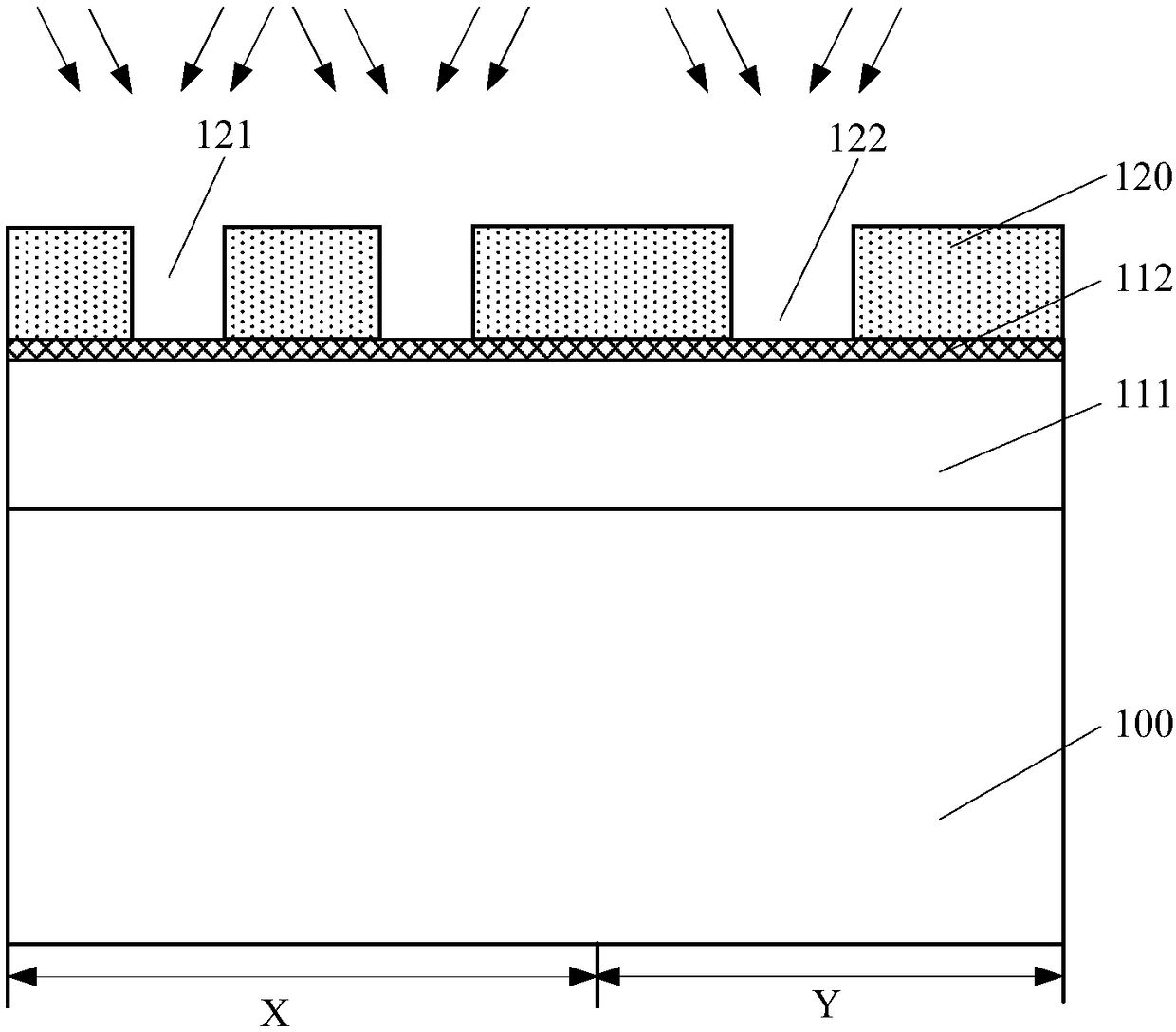

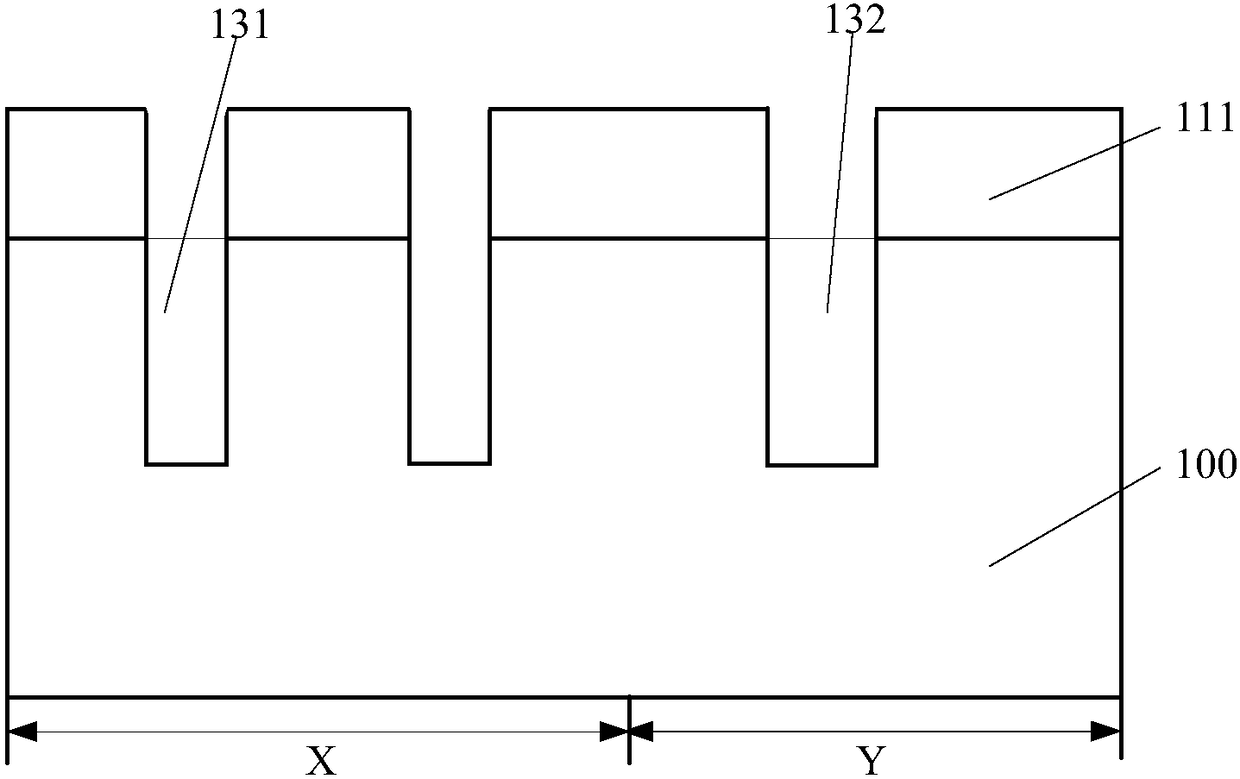

[0031] Figure 1 to Figure 3 It is a structural schematic diagram of the formation process of a semiconductor device.

[0032] refer to figure 1 , provide the layer to be etched 100, the layer to be etched 100 includes a sparse area Y and a dense area X, the layer to be etched 100 has a flat layer 111, a bottom anti-reflective layer 112 on the flat layer 111, and a bottom antireflective layer on the bottom The photoresist layer 120 on the surface of the antireflection layer 112, the photoresist layer 120 has a first mask opening 121 and a second mask opening 122 penetrating through the photoresist layer 120, the first mask opening 121 is located on the dense area, The second mask opening 122 is located on the sparse area Y.

[0033] refer to figure 2, carry out plasma treatment to the photoresist layer 120 side wall, the gas that plasma treatment adopts comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com