Constant speed sampling device of boiler water working medium

A constant velocity sampling and boiler water technology, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problem that the sample composition does not fully represent the overall working medium, and achieve the effect of reducing the difficulty of debugging, reducing costs, and ensuring sample quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further illustrate the present invention.

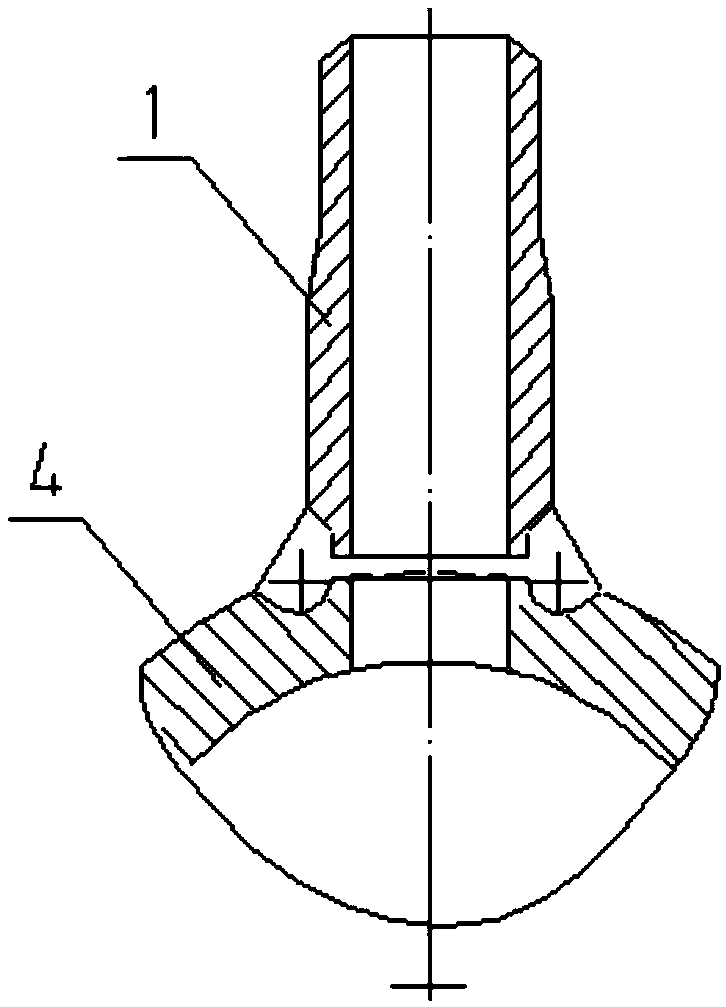

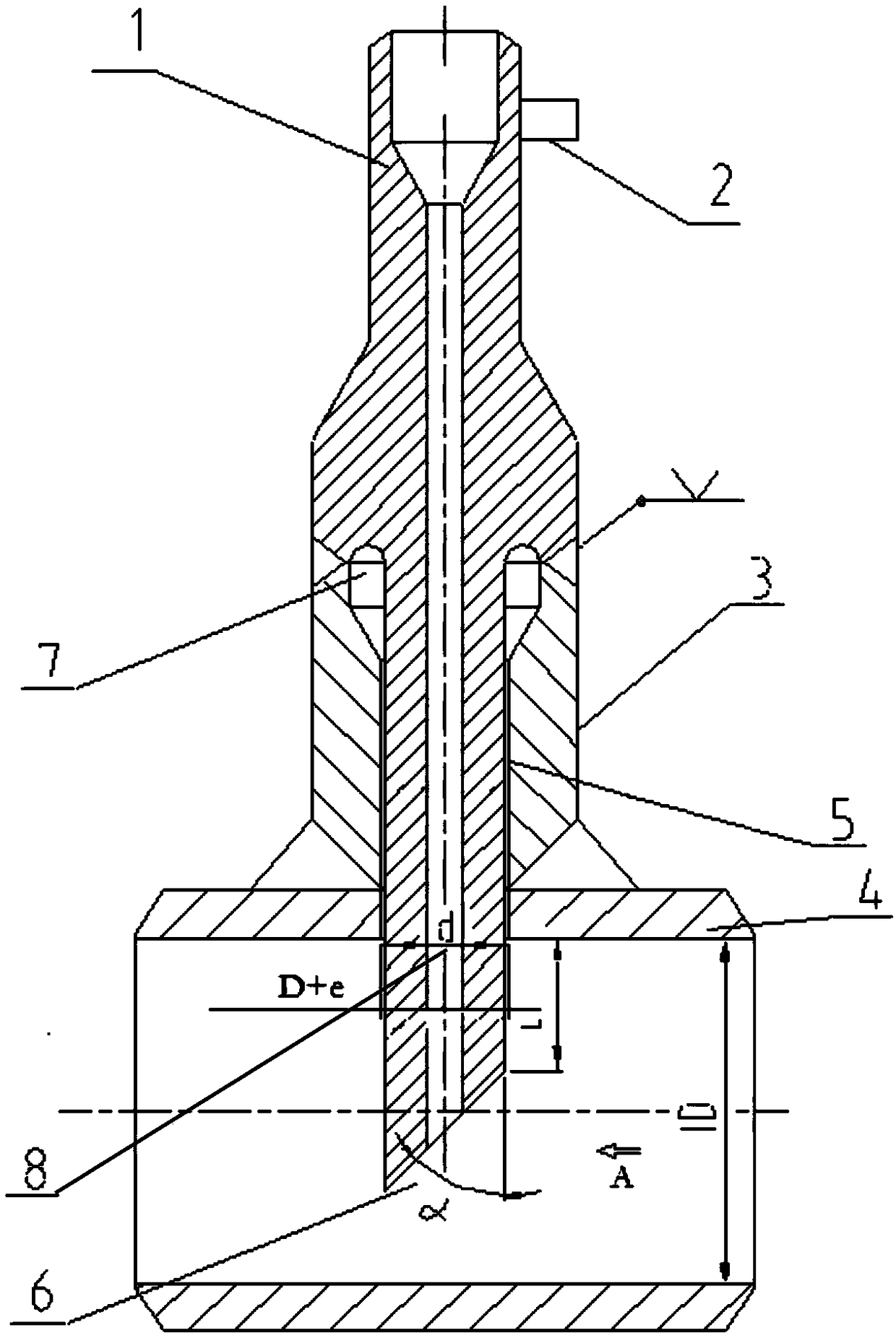

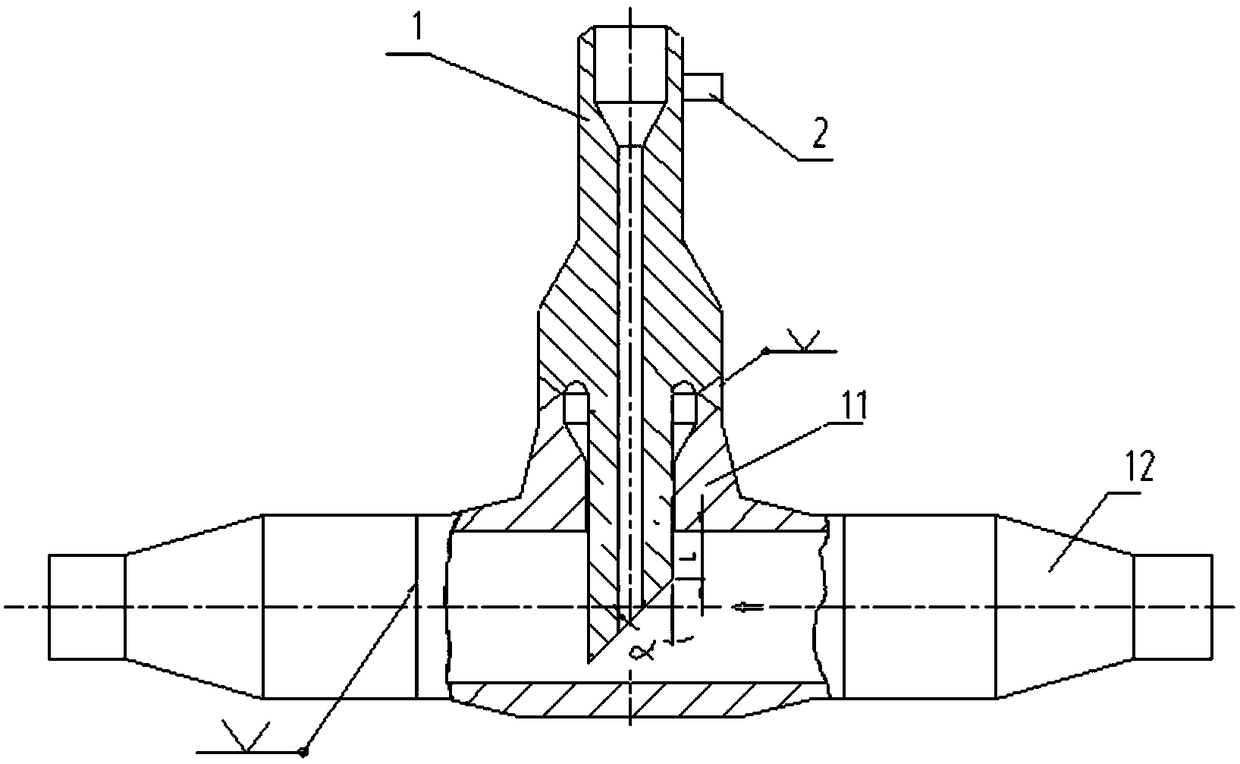

[0029] figure 2 It is a schematic diagram of a boiler hydraulic fluid constant-kinetic sampling device. The boiler hydraulic fluid constant-kinetic sampling device includes a sampling tube 1, a sign 2, a transition tube 3, a main tube 4, etc., wherein the bottom end of the transition tube 3 is connected to the main tube 4 The walls are connected vertically, and the top of the transition pipe 3 is butt-welded with the middle of the sampling pipe 1. The pipe wall of the main pipe 4 has a hole, and the lower end of the sampling pipe 1 passes through the transition pipe 3 and is inserted into the main pipe 4 . The upper end of the sampling pipe 1 is welded with an indicating steel plate 2 .

[0030] The upper end of the transition pipe 3 is provided with a flaring opening 7 to provide a gap required for material expansion during welding. The inner diameter of the root of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com