Process and equipment for manufacturing circular knitting mesh trademark bag

A production process and trademark technology, which is applied in the field of textile weaving, can solve the problems that the trademark cannot be attached to the surface of the mesh bag, the bonding strength of the trademark is not high, and the mesh gap is large, so as to avoid the trademark falling off, the appearance is beautiful and generous, and the area is increased. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A manufacturing process of a circular-woven mesh trademark bag, comprising the following steps:

[0036] (1) Rotary net weaving, weaving a round net with densely woven labeling parts using the round net textile process;

[0037] (2) Cutting the net, cutting the rotary net along the axial direction, and the cutting position is opposite to the densely woven labeling part;

[0038] (3) Unfold, tighten and unfold the cut circular net from the inside of the rotary net;

[0039] (4) Film covering, covering the densely woven labeling part with a trademark film;

[0040] (5) Rewinding, rolling up the unfolded flat net;

[0041] (6) Cutting, guide the flat net, and then cut the flat net into pieces along the direction perpendicular to the densely woven labeling part;

[0042] (7) For bag making, fold the sheet-like flat net in half so that the densely woven labeling part surrounds the waist, and then sew the adjacent two sides except for the folded edge to form a mesh bag wit...

Embodiment 2

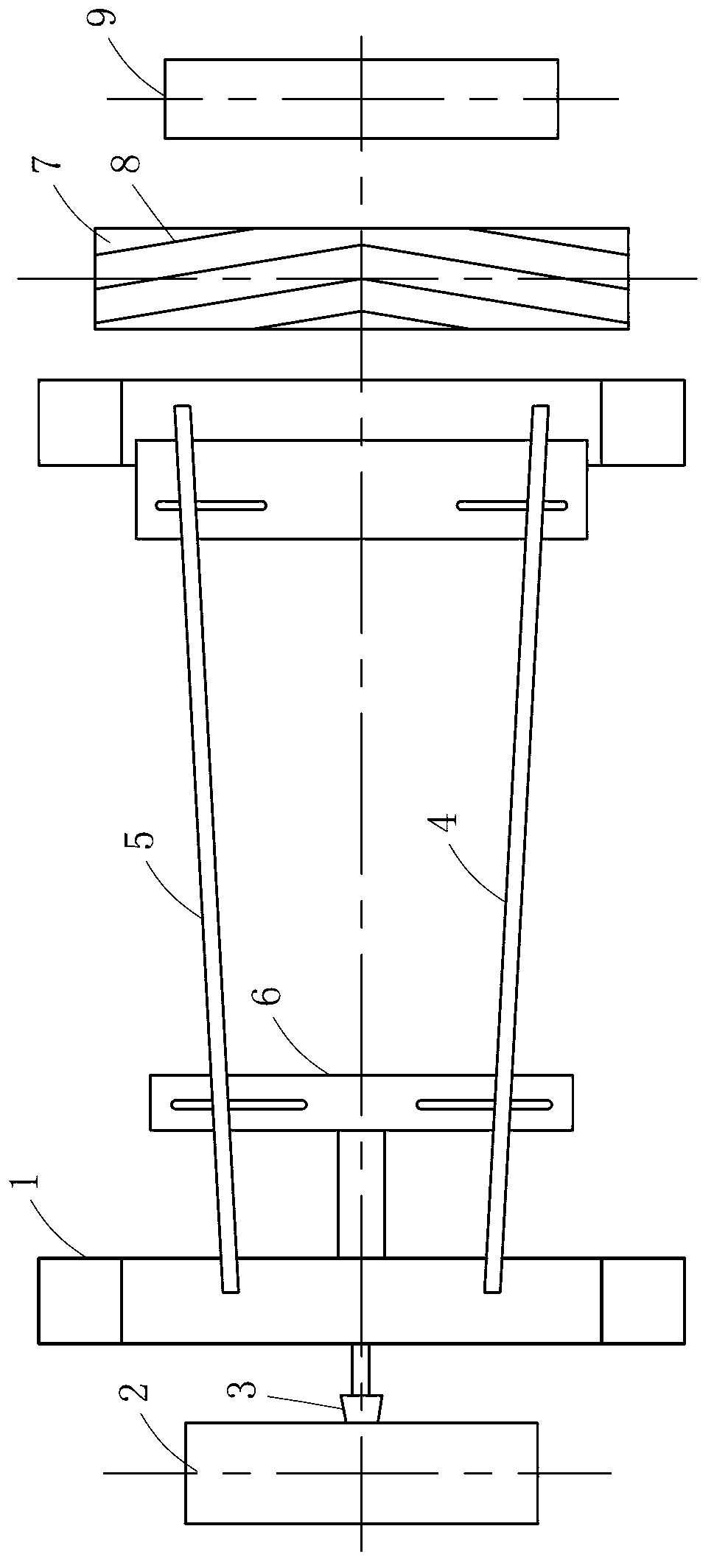

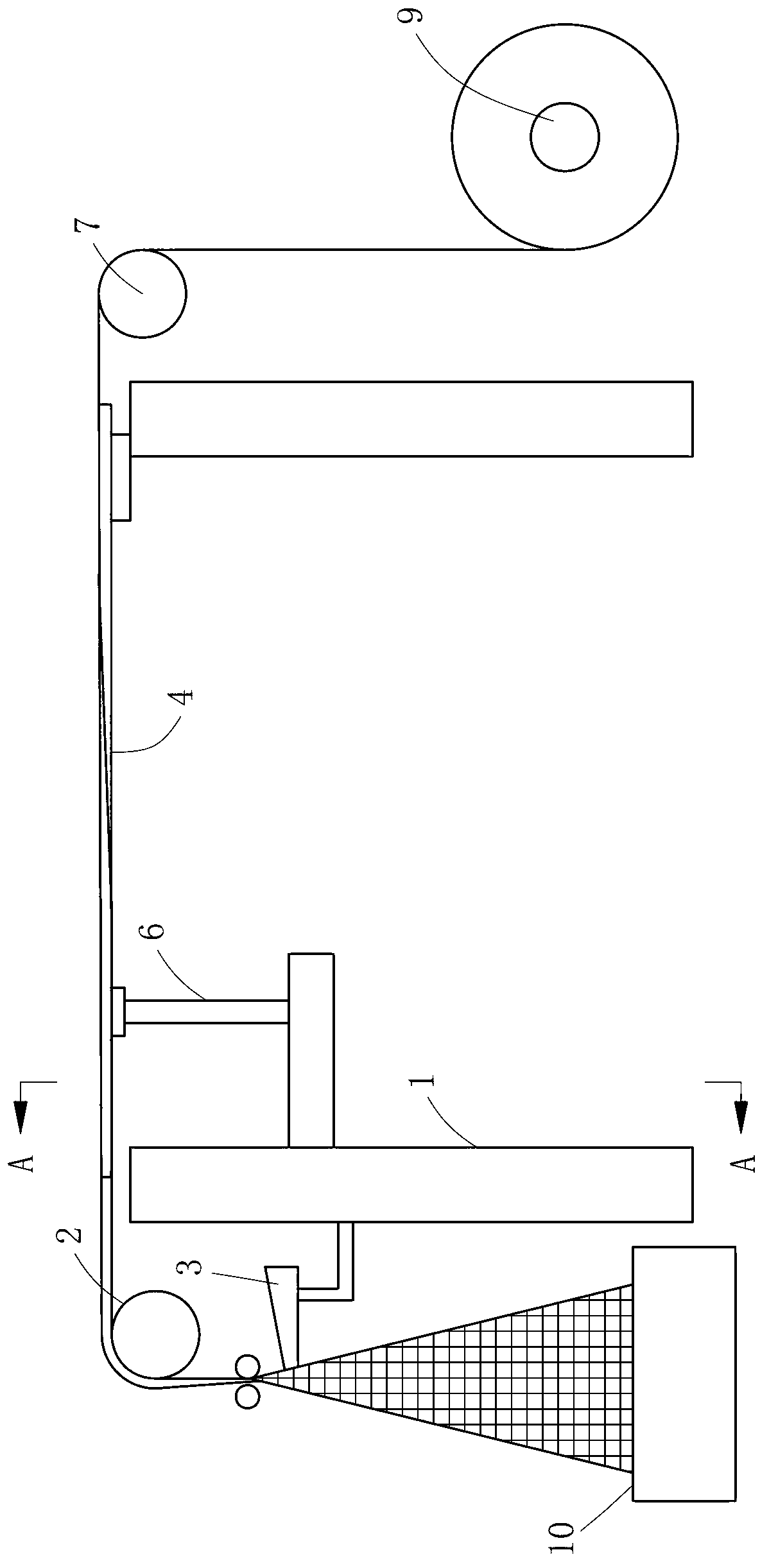

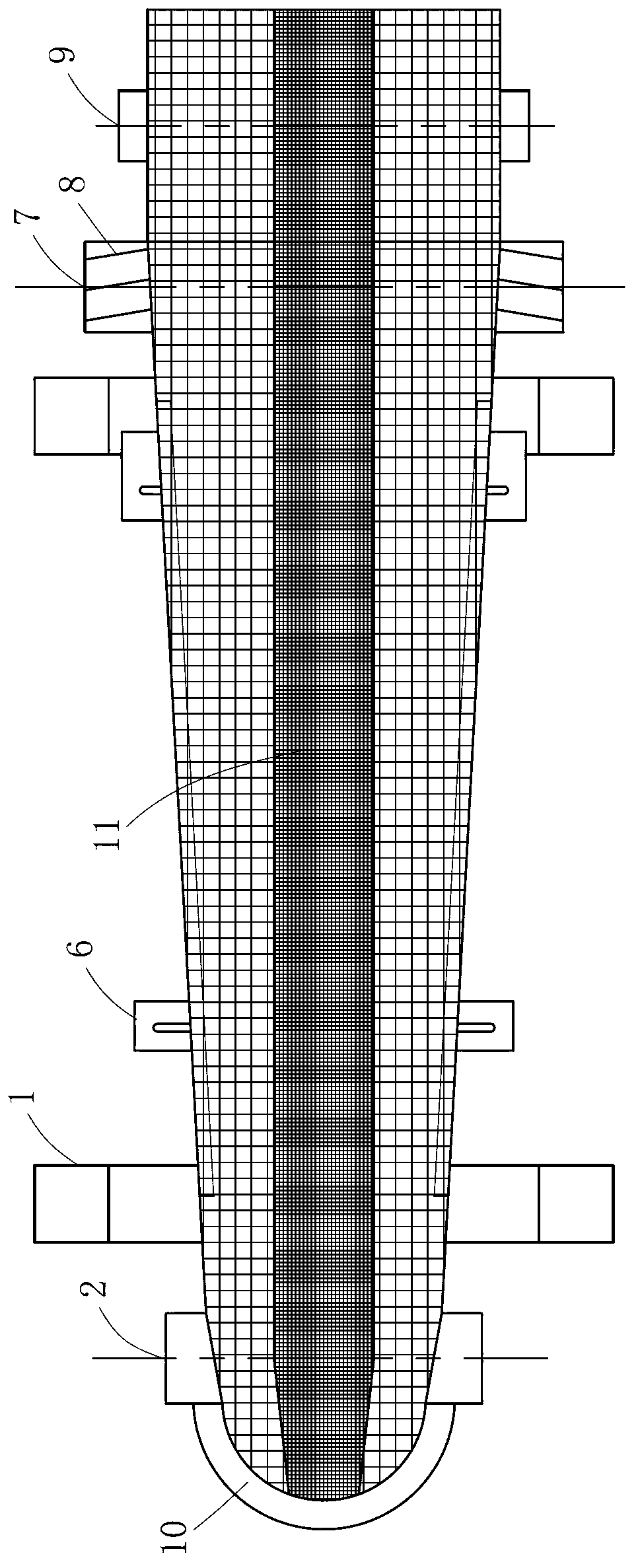

[0049] Such as figure 1 , figure 2 , image 3 with Figure 4 Commonly shown, a kind of production equipment of circular mesh trademark bag, comprises: the circular mesh loom 10 that is used to weave the rotary mesh that has closely woven labeling part 11; Net device; an unfolding device for stretching and unfolding the cut rotary net from inside the rotary net; a laminating device for covering the densely woven labeling part 11 with a trademark film; for rolling the unfolded flat net Rolling up device 9; used to fold the sheet flat net in half, so that the closely woven labeling part 11 surrounds the waist position, and then sew the adjacent two sides except the folded edge to form a mesh bag with one end open Device; according to the manufacturing process, the rotary net loom 10, the net cutting device, the unfolding device, the film covering device, the winding device 9 and the bag making device are arranged in sequence.

[0050] Among them, the rotary net weaving proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com