A swingable and self-resetting prestressed cross-laminated timber combined shear wall

A glulam, shear wall technology, applied in the direction of walls, buildings, building types, etc., can solve the problems of insufficient energy dissipation capacity, poor repairability, large residual deformation, etc., to achieve seismic energy dissipation, small residual deformation, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

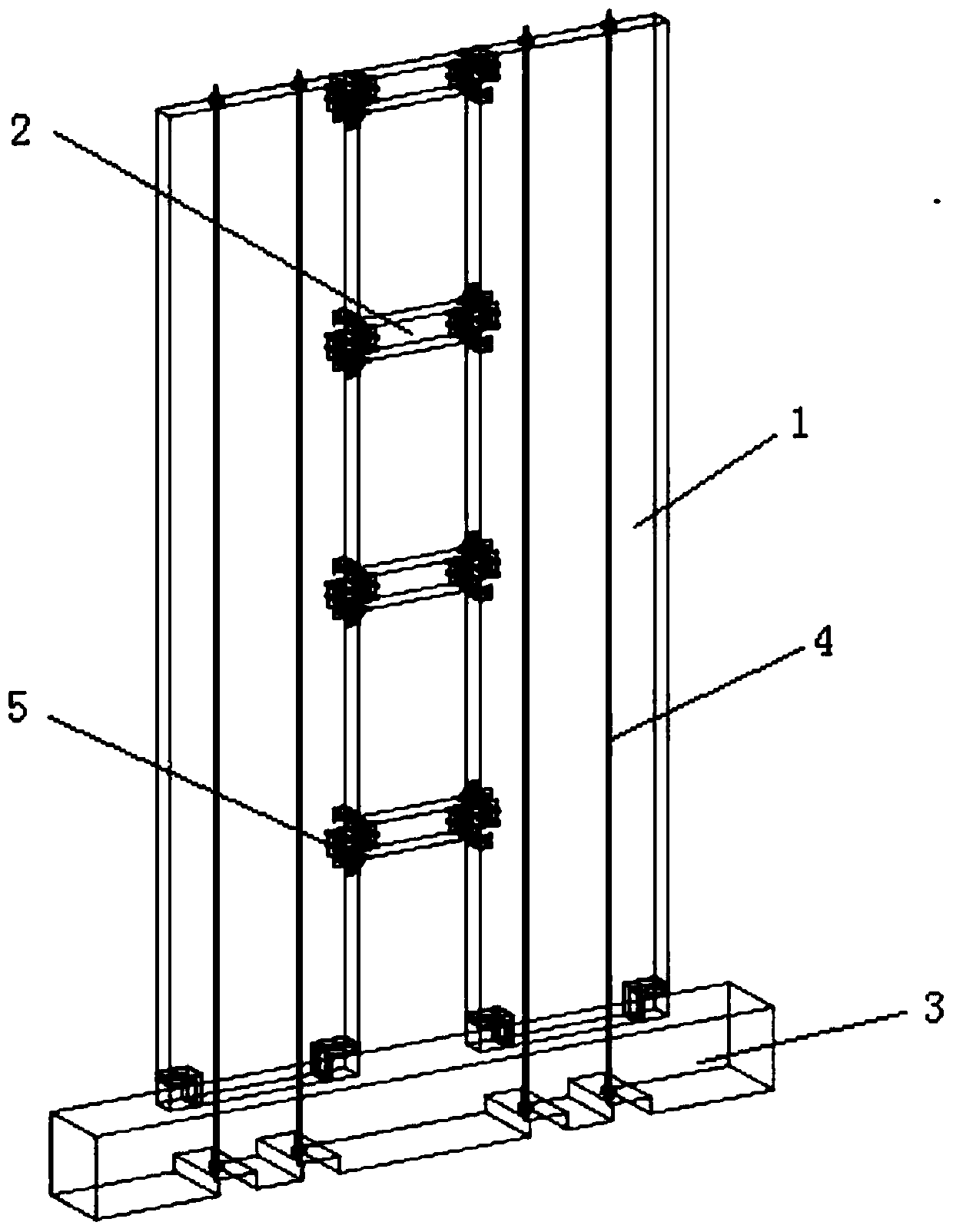

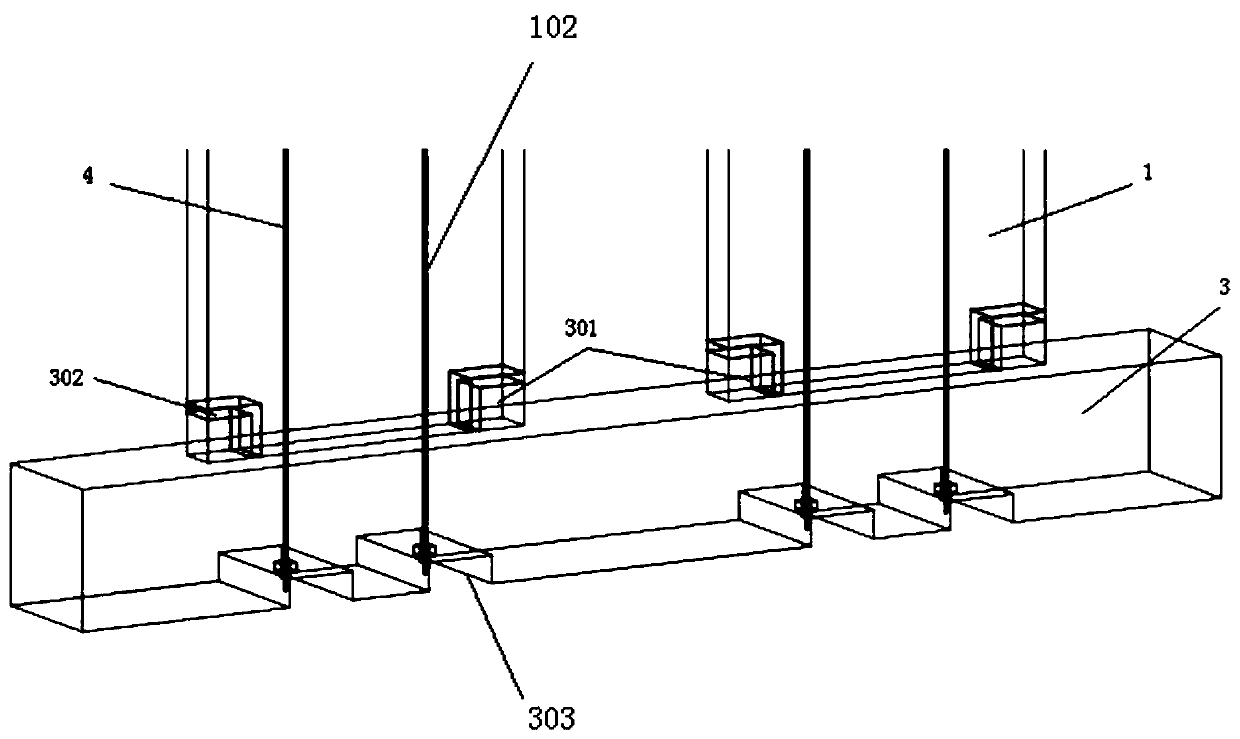

[0027] as attached Figure 1-7 As shown, a swingable self-resetting prestressed cross-glued wood combined shear wall, the shear wall includes cross-glued wood wall limb 1, cross-glued wood connecting beam 2, reinforced concrete foundation 3, pre-stressed Stress bars 4 and connectors 5;

[0028] The cross-glued wood wall plinth 1 and the reinforced concrete foundation 3 are tied together by unbonded prestressed steel bars 4, and the corner of the cross-glued timber wall pier 1 is provided with a reinforced concrete spacer 301 and the reinforced concrete foundation 3 is integrally poured , a rubber pad 302 is placed between the reinforced concrete block 301 and the contact surface of the cross-glued wood wall pier 1;

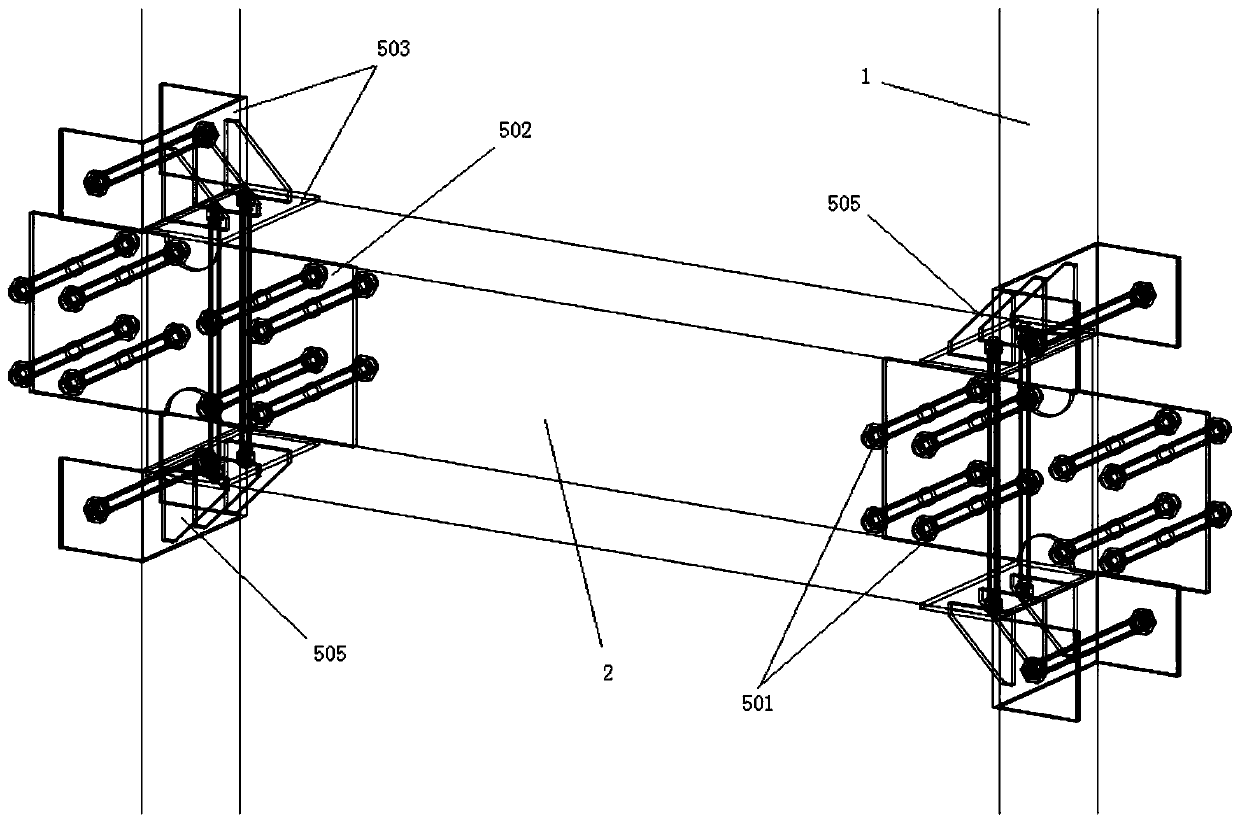

[0029] The cross-glued wood wall plinth 1 and the cross-glued wood connecting beam 2 are tightly connected by a connecting piece 5, and the connecting piece 5 includes a bolt 501, an inner filling steel plate 502, an outsourcing steel plate 503, and an outsourcin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com