Prestressed reinforced concrete precast column vertical connecting structure and construction method thereof

A technology of reinforced concrete and prestressed tendons, which is applied in the direction of structural elements, building components, building structures, etc., can solve problems such as incomplete grouting of grouting sleeves, large amount of grouting sleeves, and difficulties in concrete pouring, etc. The use of formwork and supports, the reduction of wet work, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

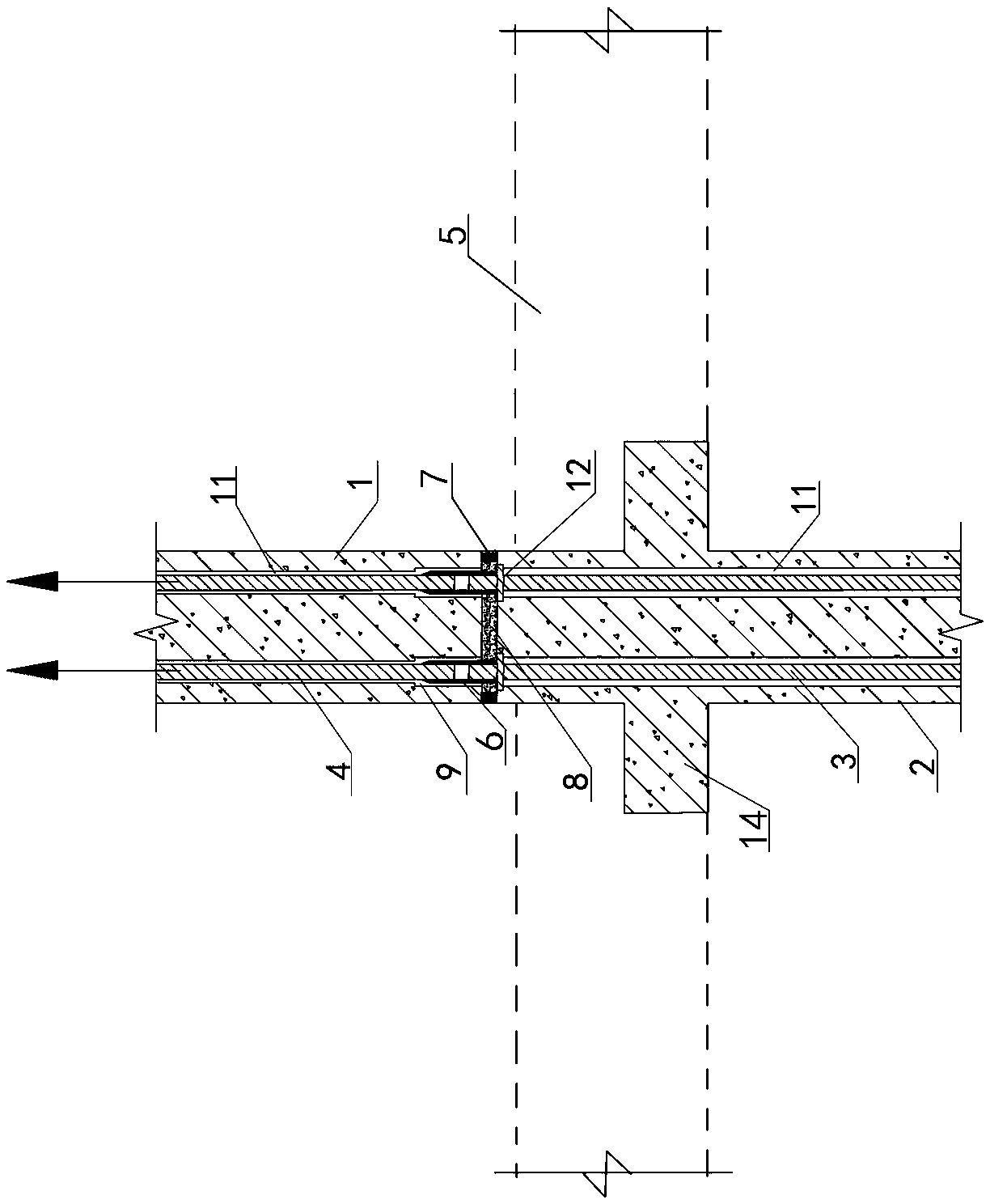

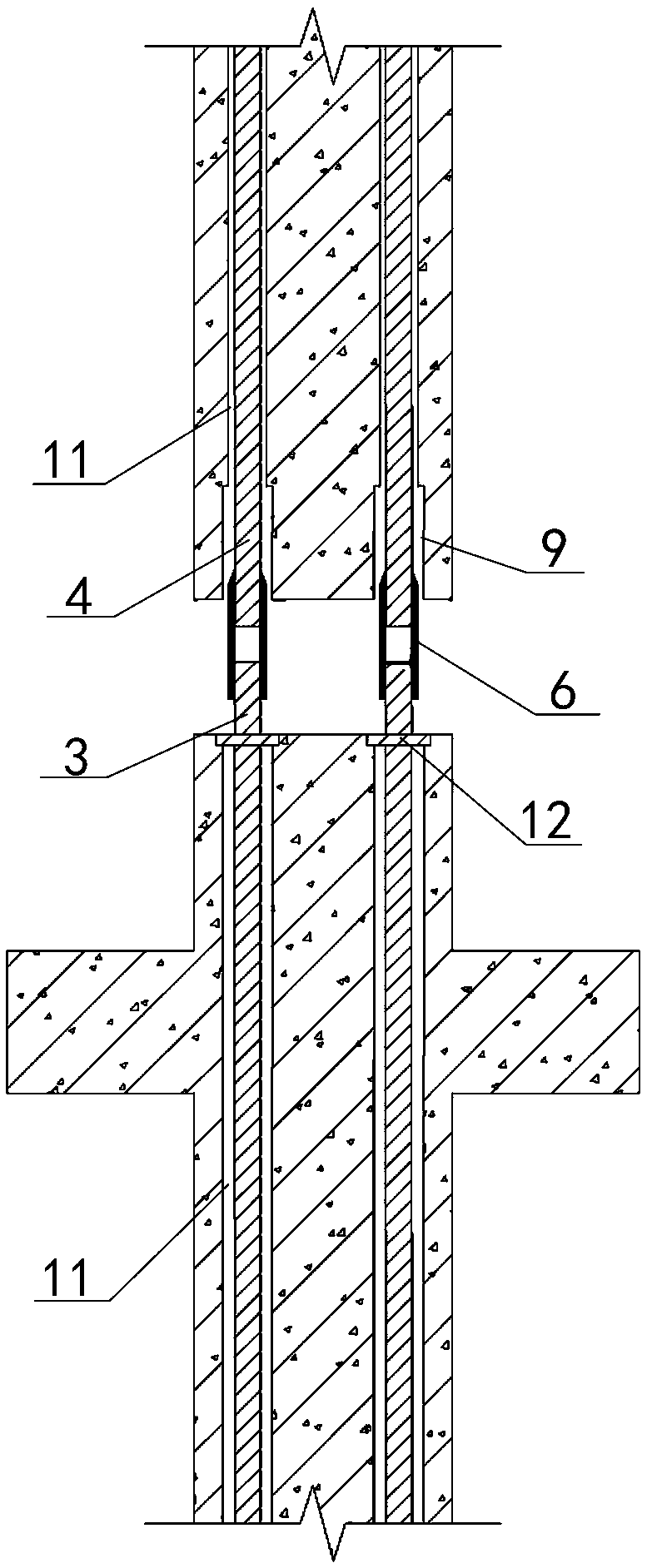

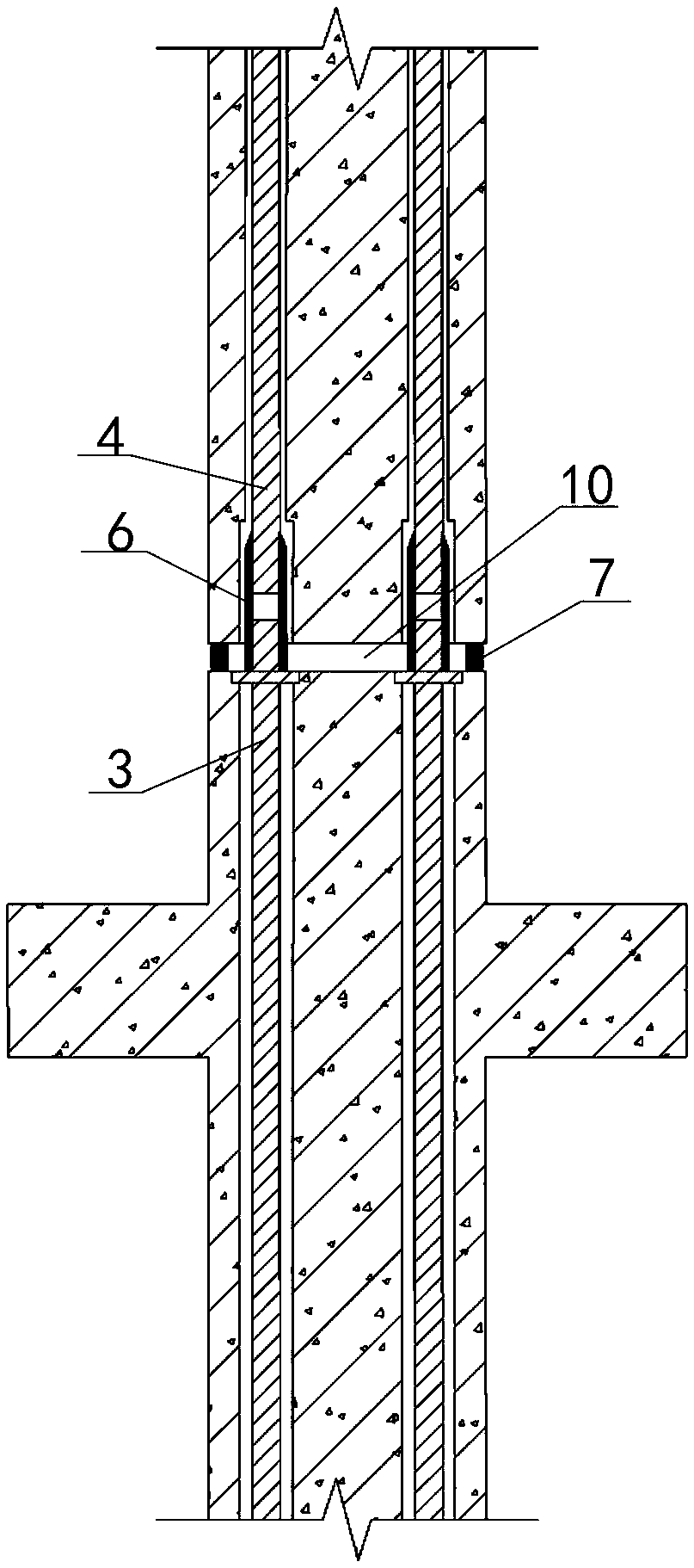

[0044] Examples see Figure 1-5 As shown, a pre-stressed reinforced concrete precast column vertical connection structure includes an upper reinforced concrete precast column 1 and a lower reinforced concrete precast column 2, where the lower reinforced concrete precast column 2 and the upper reinforced concrete precast column 1 connect nodes It is located above the connection node of the lower-level reinforced concrete precast column 2 and the frame beam 5.

[0045] The lower reinforced concrete precast column is provided with a set of long vertical prestressed holes, and each prestressed hole is penetrated with a lower column prestressed tendon 3, and the top of the lower reinforced concrete precast column 2 is embedded with prestress Anchor 12, the lower column pre-stressed tendons 3 extend upwards from the top surface of the lower-layer reinforced concrete precast column 2, the pre-stressed anchor 12 is sleeved on the lower-layer column pre-stressed tendons 3 and its top side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com