universal joint

A technology of universal joints and intermediate joints, which is applied in the field of universal joints, can solve the problems of weak structural joints of universal joints, extrusion of universal joints, increased torque, etc., to achieve strong practicability and economy, fast connection, The effect of reducing the replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

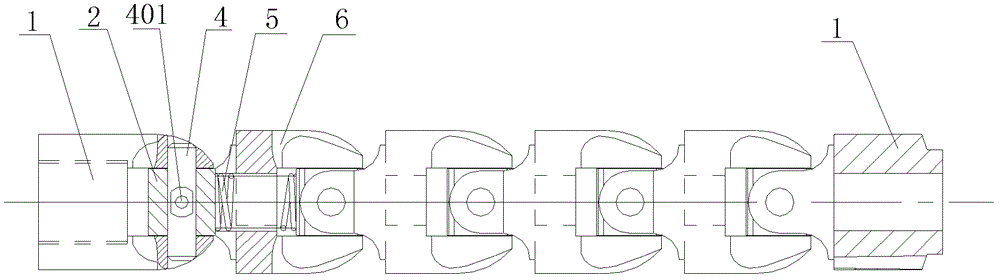

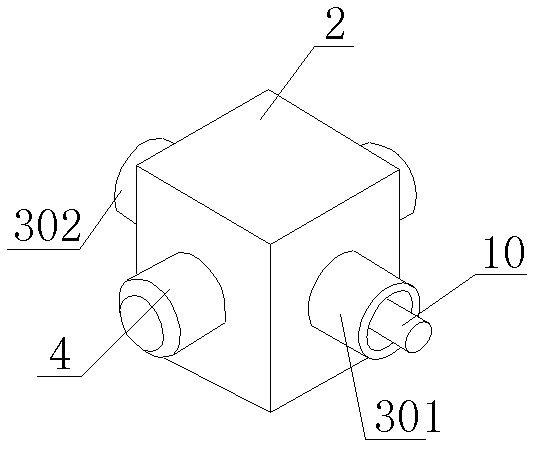

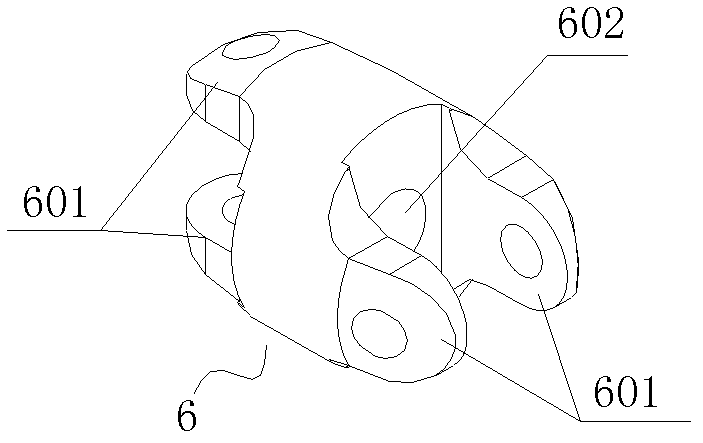

[0023] figure 1 It is a structural schematic diagram of a preferred embodiment of the universal joint of the present invention. Such as figure 1 As shown, the universal joint includes the end joints 1 arranged at both ends for connecting with other workpieces, the middle joint 6 for adjusting the length, and the joints between the end joints 1 and the middle joints, etc. Connection assembly for connection. Figure 4 It is a schematic structural diagram of the end connecting joint of a preferred embodiment of the universal joint of the present invention; Figure 5 It is a structural sectional view of the end connection joint of the preferred embodiment of the universal joint of the present invention. Such as Figure 4 and Figure 5 As shown, one end of the end connection section 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com