Phase change energy storage sleeve-type geothermal heat exchanger

A phase change energy storage and heat exchanger technology, which is applied in the types of heat exchangers, indirect heat exchangers, heat storage equipment, etc., and can solve the problems of thermal short circuit of inlet and outlet pipelines, large heat influence radius, and low heat exchange efficiency. , to achieve the effect of increasing heat exchange, saving floor space and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

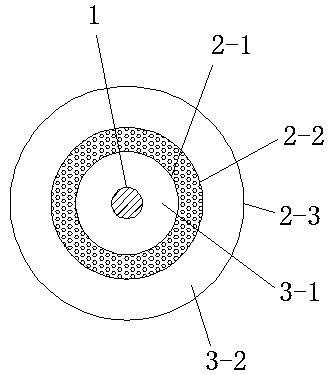

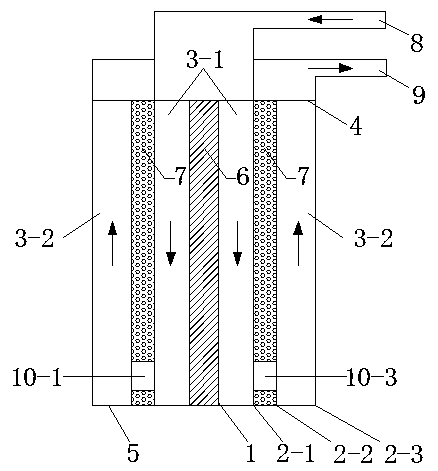

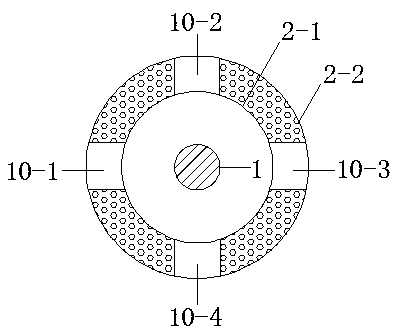

[0017] Such as Figure 1-4 As shown, a phase change energy storage casing type geothermal heat exchanger, the geothermal heat exchanger consists of a central tube 1, a first casing 2-1, a second casing 2-2, a third casing 2-3, The first annular channel 3-1, the second annular channel 3-2, the top cover plate 4, the bottom cover plate 5, the phase change material 6 in the summer working condition, the phase change material 7 in the winter working condition, the water inlet pipe 8 and the water outlet pipe 9 ; The center pipe 1 is placed at the center of the geothermal heat exchanger, and the first sleeve pipe 2-1, the second sleeve pipe 2-2 and the third sleeve pipe 2-3 take the center of the central pipe 1 as the center and increase along the radius The direction is set on the outside of the central tube 1 in turn; the first annular channel 3-1 is formed by the space surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com