Mechanical limiting structure

A limit mechanism and mechanical technology, applied in the direction of mechanical equipment, brake type, etc., can solve the problem of large bending force of the shaft system, and achieve the effect of good buffering effect and large rotation angle range of the shaft system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

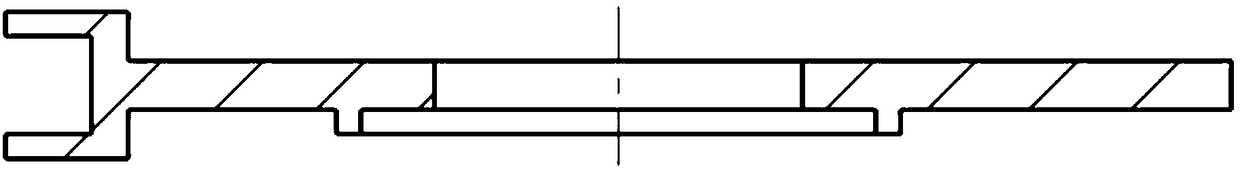

[0022] Such as figure 1 , figure 2 As shown, a novel mechanical limit mechanism of the present invention consists of a bumper 1, a limiter bracket 2, a No. 1 limiter seat 3, a No. 1 pressure rod 4, a No. 1 spring 5, a No. 1 screw plug 6, and two No. 1 limiter seat 7, No. 2 pressure rod 8, No. 2 spring 9, and No. 2 screw plug 10; No. 1 limiter seat 3, No. 1 pressure rod 4, No. 1 spring 5, and No. 1 screw plug 6 No. 1 limiter assembly; No. 1 pressure rod 4, No. 1 spring 5, and No. 1 screw plug 6 are installed in series along the axis of the cylindrical stepped hole of No. 1 limiter seat 3, and the No. The impact transmitted by the pressure rod 4 is used for buffering and vibration reduction; the second stopper seat 7, the second pressure rod 8, the second spring 9, and the second screw plug 10 form the second stopper assembly; one second pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com