Fabricated composite shear wall based on self-resetting composite end column-grouting anchor shear wall

A shear wall and self-resetting technology, applied to walls, protective buildings/shelters, building components, etc., can solve the lack of market competitiveness theory of cast-in-place concrete structures, large workload of steel bar binding, low construction efficiency, etc. problems, achieve excellent technical and economic benefits, reduce post-earthquake repair costs, and facilitate design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described below in conjunction with specific embodiments.

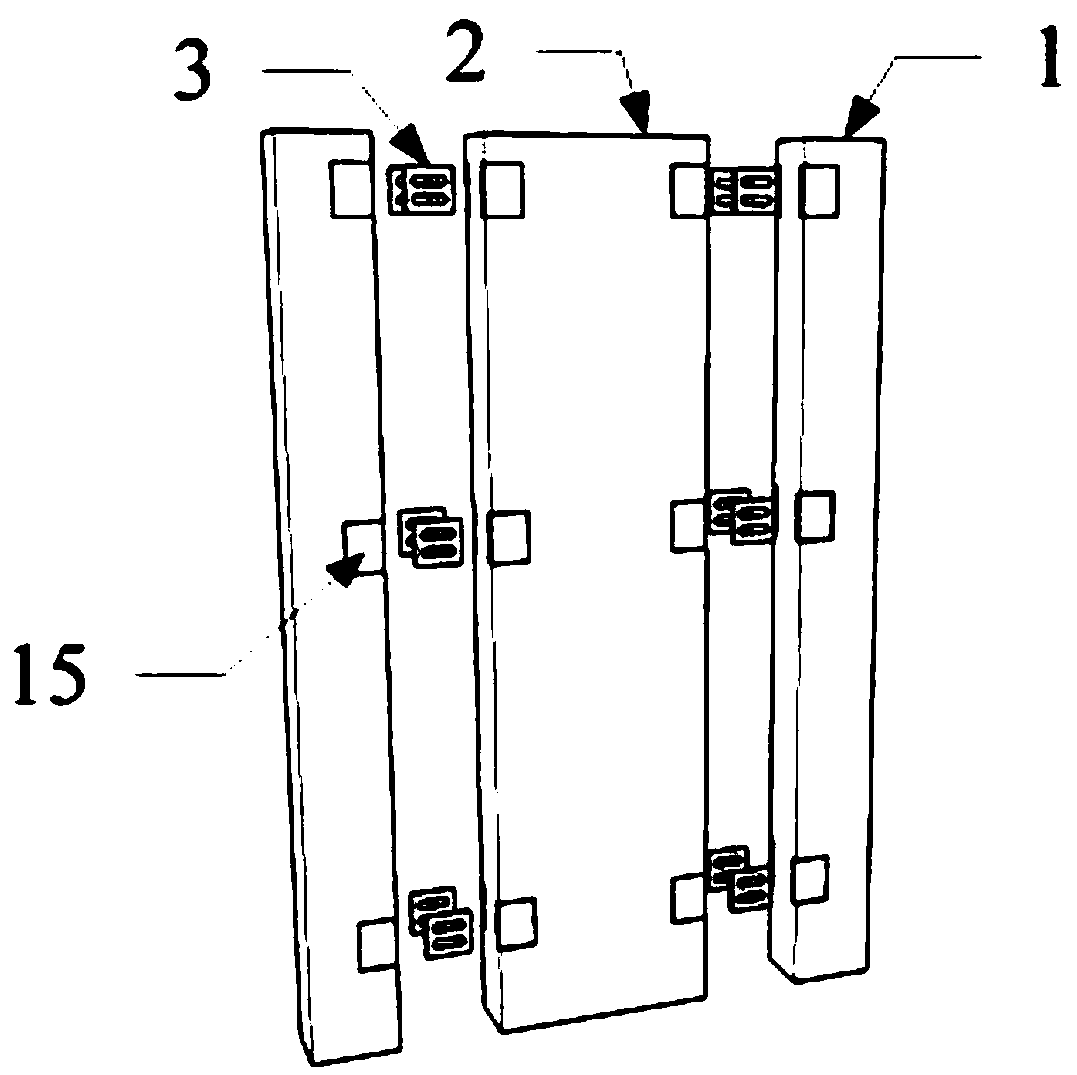

[0025] Such as Figure 1 to Figure 4 Shown: It is a schematic diagram of the structure of the assembled composite shear wall based on the self-resetting composite end column-grout anchor shear wall of the present invention.

[0026] The assembled composite shear wall based on the self-resetting combined end column-slurry anchor shear wall of the present invention includes: self-resetting combined end column 1: an outer layer of rectangular steel pipe 4, an inner layer of round steel pipe 5, and a column steel bar 7 , column concrete 8, the inner round steel pipe 5 is provided with unbonded prestressed steel bars 6 for the connection of the upper and lower self-resetting composite end columns 1 on the construction site;

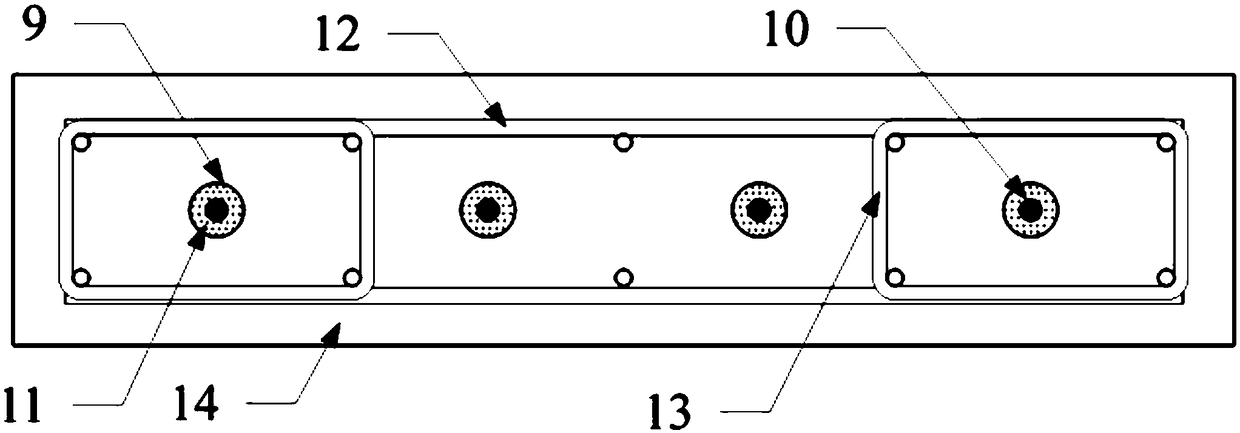

[0027] Slurry anchor shear wall 2: composed of slurry anchor bellows 9, shear wall reinforcement mesh 12, shear wall stirrup 13 and shear wall conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com