Pavement pit slot repairing structure

A technology of pits and cement emulsified asphalt, applied in the field of repairing structures, can solve the problems of low initial strength, temperature sensitivity, low bonding strength, etc., and achieve the effects of stable sealing, high elongation and low modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

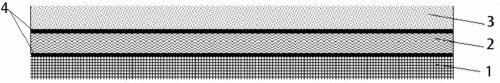

[0015] The pavement pothole repair structure of this embodiment includes a geogrid layer 1, a cement emulsified asphalt mortar layer 2 and a cement emulsified asphalt concrete layer 3 arranged sequentially from bottom to top in the pit to be repaired. Adhesive layer 4 is set between layer 1, cement emulsified asphalt mortar layer 2, cement emulsified asphalt concrete layer 3 and the inner surface of the pit to be repaired;

[0016] The adhesive raw material includes the following components by weight: 30 parts of epoxy resin, 15 parts of ethylene glycol butyl ether, 5 parts of n-butanol, 5 parts of methacrylic acid, 1 part of styrene, 10 parts of triethylene glycol diester, 2 parts of poly-2,6-dimethyl-1,4-phenylene ether, 5 parts of polyvinyl acetate, 5 parts of dimethylethanolamine, α, ω-dihydroxy polydimethyl 5 parts of base siloxane, 1 part of nano-silica, 1 part of graphite powder, 3 parts of tackifier, 1 part of chain extender, 1 part of crosslinking agent, and parts of ...

Embodiment 2

[0018] The pavement pothole repair structure of this embodiment includes a geogrid layer 1, a cement emulsified asphalt mortar layer 2 and a cement emulsified asphalt concrete layer 3 arranged sequentially from bottom to top in the pit to be repaired. Adhesive layer 4 is set between layer 1, cement emulsified asphalt mortar layer 2, cement emulsified asphalt concrete layer 3 and the inner surface of the pit to be repaired;

[0019] The adhesive raw material includes the following components by weight: 40 parts of epoxy resin, 25 parts of ethylene glycol butyl ether, 15 parts of n-butanol, 10 parts of methacrylic acid, 5 parts of styrene, methacrylic acid dicondensate 20 parts of triethylene glycol diester, 6 parts of poly-2,6-dimethyl-1,4-phenylene ether, 10 parts of polyvinyl acetate, 10 parts of dimethylethanolamine, α, ω-dihydroxy polydimethyl 10 parts of base siloxane, 5 parts of nano-silica, 5 parts of graphite powder, 15 parts of tackifier, 3 parts of chain extender, 3 p...

Embodiment 3

[0021] The pavement pothole repair structure of the present embodiment, the road surface pothole repair structure of the present embodiment, comprises the geogrid layer 1, the cement emulsified asphalt mortar layer 2 and the cement emulsified asphalt mortar layer 2 which are sequentially arranged in the pothole to be repaired. An asphalt concrete layer 3, an adhesive layer 4 is arranged between the geogrid layer 1, the cement emulsified asphalt mortar layer 2, the cement emulsified asphalt concrete layer 3 and the inner surface of the pit to be repaired;

[0022] The adhesive raw material includes the following components by weight: 30 parts of epoxy resin, 25 parts of ethylene glycol butyl ether, 55 parts of n-butanol, 10 parts of methacrylic acid, 1 part of styrene, 20 parts of triethylene glycol diester, 2 parts of poly 2,6-dimethyl-1,4-phenylene ether, 10 parts of polyvinyl acetate, 5 parts of dimethylethanolamine, α, ω-dihydroxy polydimethyl 10 parts of base siloxane, 1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com