Waterproof component for pipeline to pass through floor and mounting method thereof

A technology of waterproof components and installation methods, applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve the problems of gaps between working pipes and embedded casings, loss of waterproof performance, gaps in flexible materials, etc., to facilitate replacement. , The effect of stable waterproof effect and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

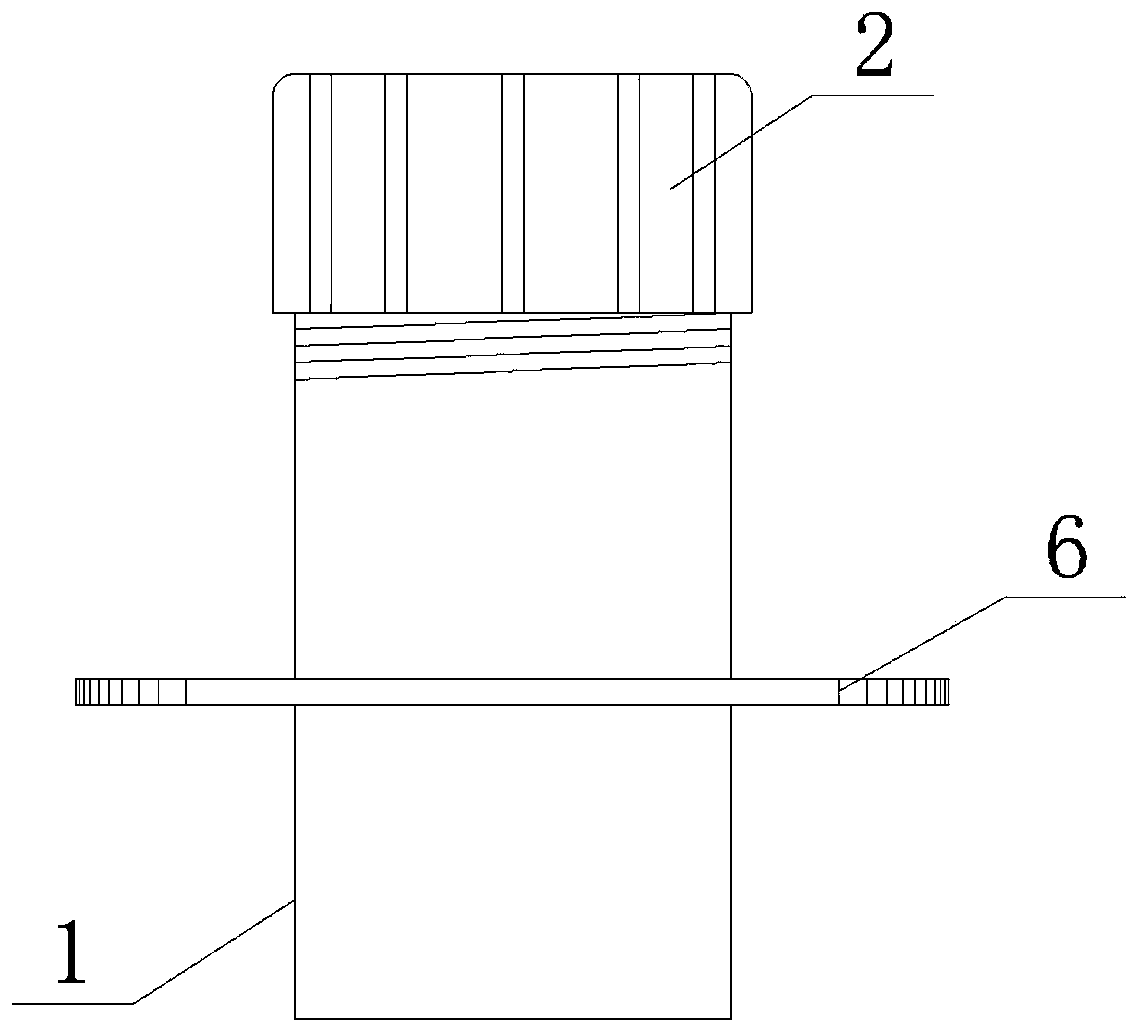

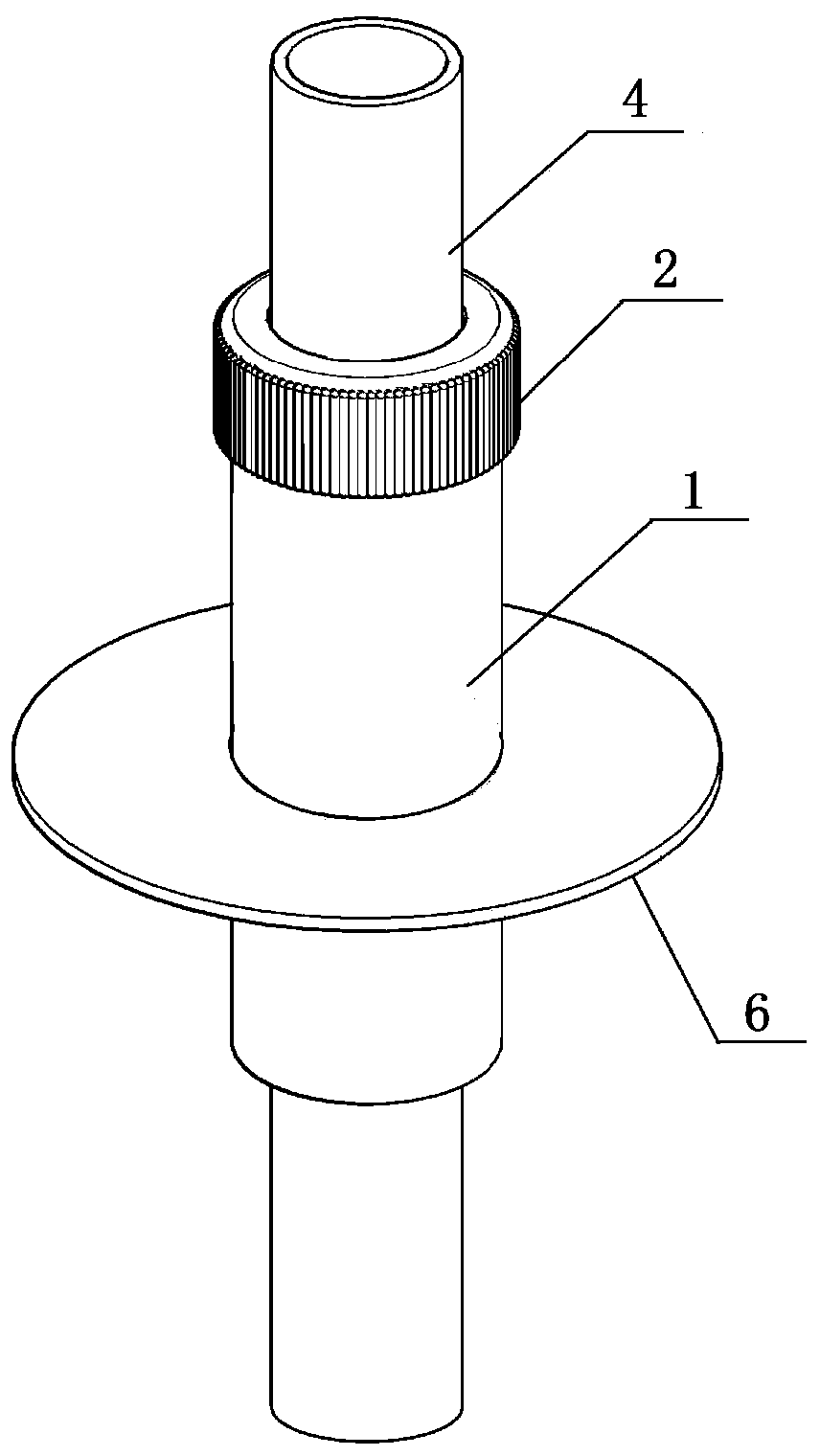

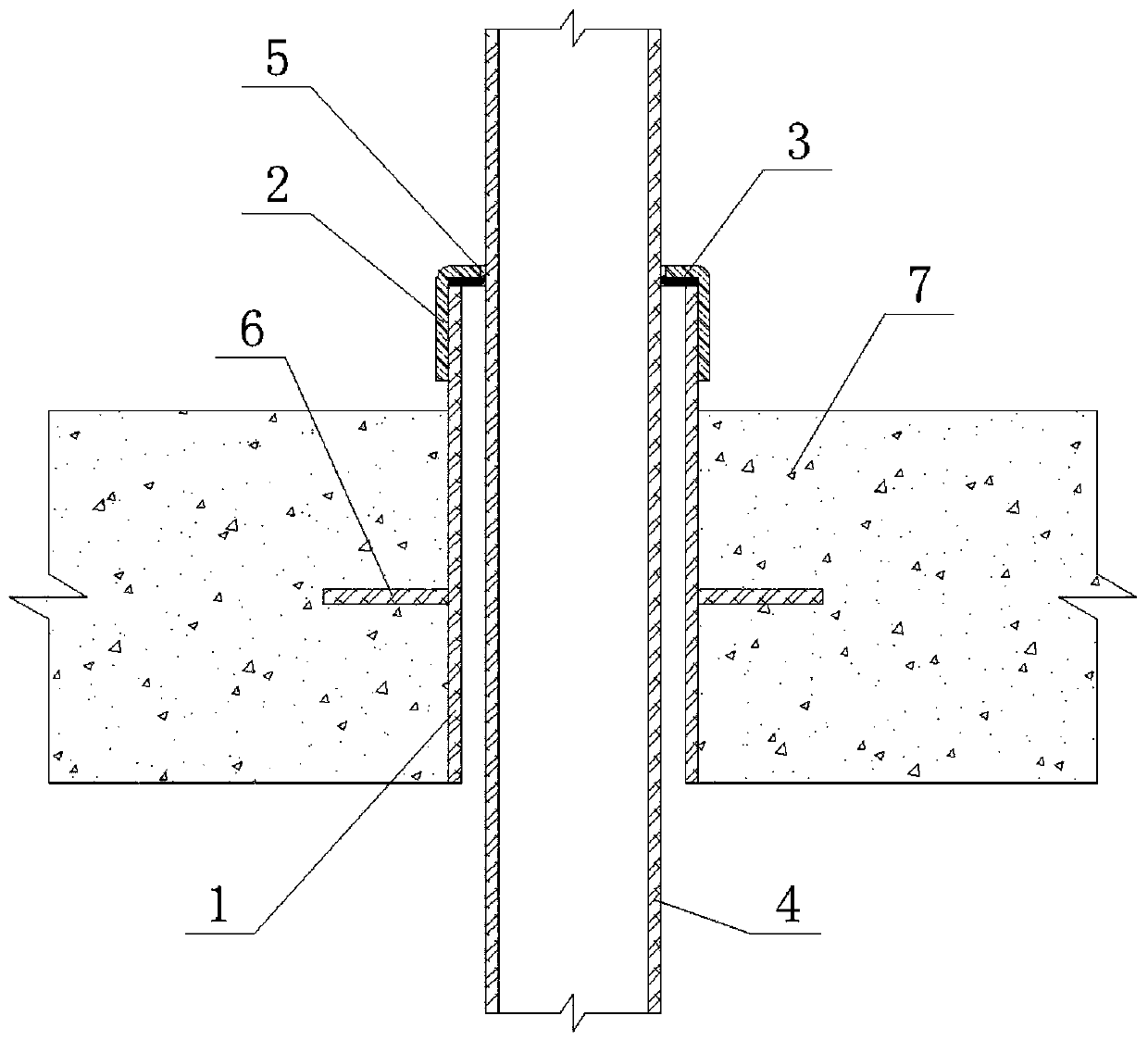

[0028] Specific implementation mode one: combine figure 1 , figure 2 , image 3 with Figure 4 Describe this embodiment, in this embodiment, the working tube 4 is installed in the outer tube 1, the gap between the working tube 4 and the outer tube 1 is matched, the cap 2 is set on the working tube 4, and the open end of the cap 2 faces the outer tube 1 setting, the inner wall of the cap 2 is detachably connected to the outer wall of the outer sleeve 1, the gasket 3 is set on the working tube 4 and it is in the cap 2, and the inner hole of the gasket 3 is closely attached to the outer wall of the working tube 4.

[0029] In this embodiment, the upper end surface of the gasket 3 is closely attached to the inner top wall of the cap 2 .

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment is a further limitation of Embodiment 1. In this embodiment, the top surface of the cap 2 is processed with a through hole 5 matching the working tube 4, and the outer diameter of the working tube 4 is smaller than the aperture of the through hole 5. .

specific Embodiment approach 3

[0031] Specific embodiment three: this embodiment is a further limitation of specific embodiment one or two, the outer wall of the outer casing 1 is provided with a water stop ring 6, and the water stop ring 6 is fixedly set on the outer casing 1, preferably integrally made connection method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com