Aqueous carbon fiber sizing agent and preparation method of same

A technology of carbon fiber and hydrophilic emulsifier, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc. It can solve the problems of long synthesis cycle, affecting the surface interface performance of carbon fiber, and affecting the mechanical properties of composite materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

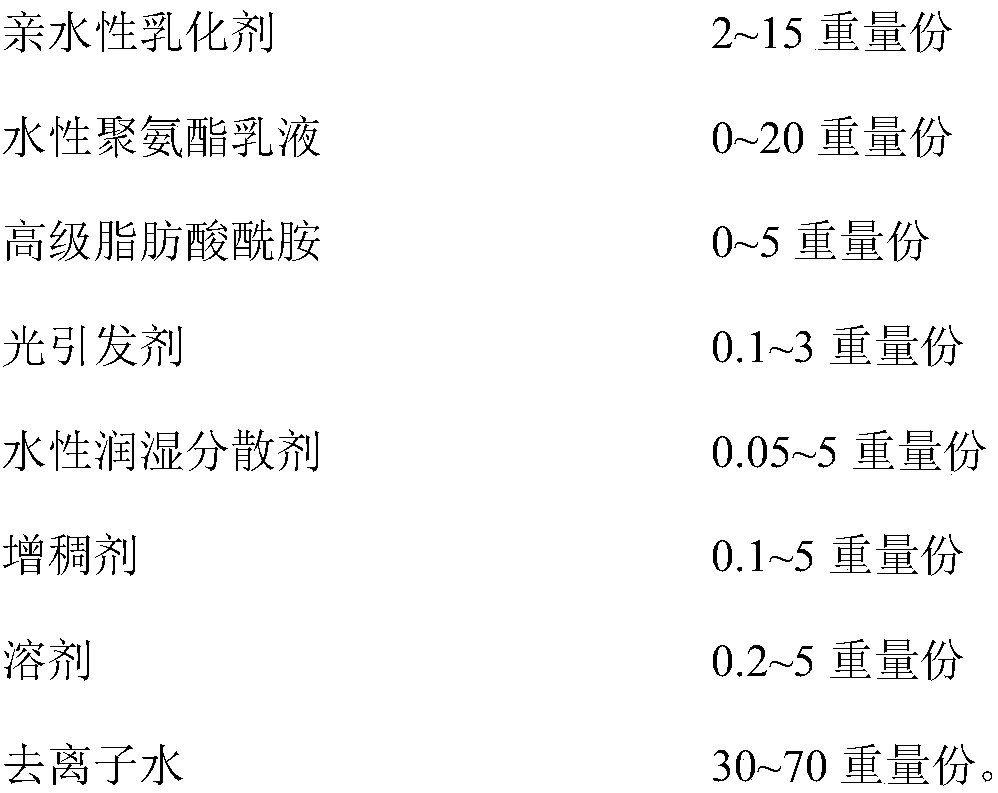

[0066] According to a typical embodiment of the present invention, a water-based carbon fiber sizing agent is provided. This water-based carbon fiber sizing agent is made of the following components by weight:

[0067]

[0068] The water-based carbon fiber sizing agent of the present invention is a water-based carbon fiber sizing agent combined by heat curing and light curing. The carbon fiber after the sizing can be dried by high-temperature heat drying, and then cured by light curing, so that the carbon fiber The performance of the sizing agent is further improved; the combination of thermal curing and light curing provided by the present invention improves the production efficiency of the carbon fiber sizing agent, enhances the clustering of the fiber bundles, and is not easy to shed crumbs during the weaving process, and can be combined with the ring Perfect combination with epoxy resin prepreg.

[0069]Preferably, the added amount of epoxy resin is 22 to 35 parts by w...

Embodiment 1

[0102] The carbon fiber sizing agent of this embodiment is made by the following components (table 4) by weight after curing and photocuring:

[0103] Table 4

[0104]

[0105] The preparation method is as follows:

[0106] Add 24 parts of 0161 (E-54) (Bluestar Nantong Xingchen Synthetic Material), 6 parts of N-740 (Bluestar Nantong Xingchen Synthetic Material), and 1 part of propylene glycol methyl ether solvent into a mixing bucket with a condenser. Raise the temperature to 90°C, stir and disperse for 1 hour, and the stirring speed is 800r / min, so that the epoxy resin is mixed evenly. Then, under the condition of uniform stirring, slowly add 8 parts of BOM-25 into the above epoxy resin system to make it uniformly dispersed in the epoxy resin, stirring time is 1 hour, stirring speed is 1000r / min. Then, lower the temperature to 80°C, add 0.35 parts of wetting and dispersing agent ANTI-TERRA-250 to make it evenly dispersed in the system. Then, lower the temperature to 65°...

Embodiment 2

[0108] The carbon fiber sizing agent of this embodiment is made by the following components (Table 5) by weight after curing and photocuring:

[0109] table 5

[0110]

[0111] The preparation method is as follows:

[0112] Add 23 parts of WSR618 (E-51) (Bluestar Nantong Xingchen Synthetic Materials) and 0.7 parts of oleic acid amide into a mixing tank with a condenser, raise the temperature to 150°C, stir for 1 hour, and the stirring speed is 600r / min . Lower the system temperature to 90°C, add 6 parts of N-740S (Bluestar Nantong Xingchen Synthetic Material) and 1 part of propylene glycol methyl ether solvent, stir and disperse for 1 hour, and the stirring speed is 800r / min, so that the epoxy resin is mixed evenly. Then, lower the temperature to 80°C, and slowly add 8.5 parts of BOM-25 to the above epoxy resin system under uniform stirring to make it evenly dispersed in the epoxy resin. The stirring time is 1 hour and the stirring speed is 1000r / min. . Then, lower the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com