Polyphosphate piperazine and preparation method and application thereof

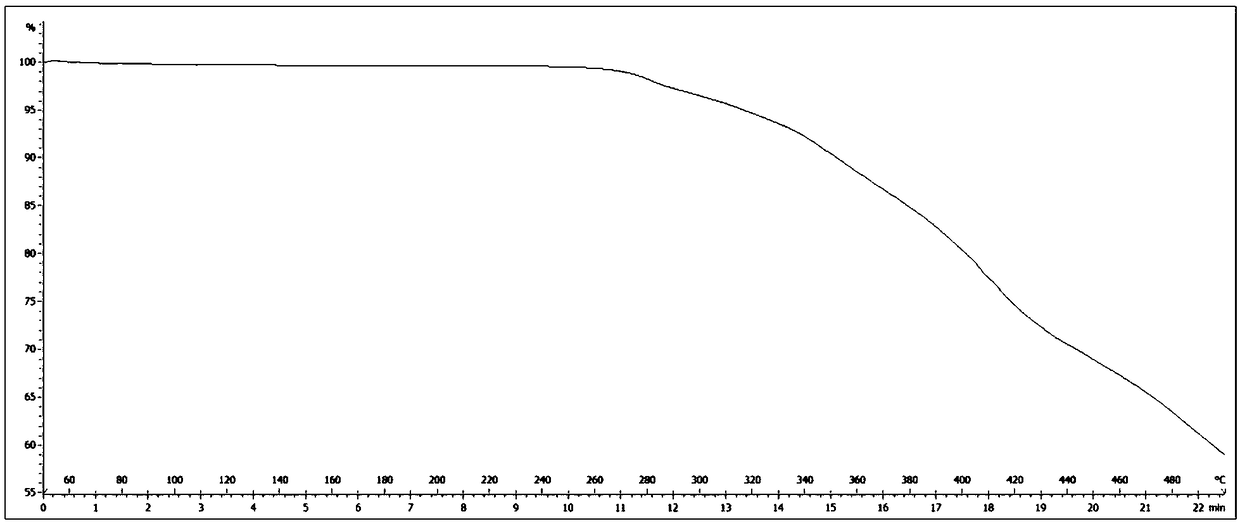

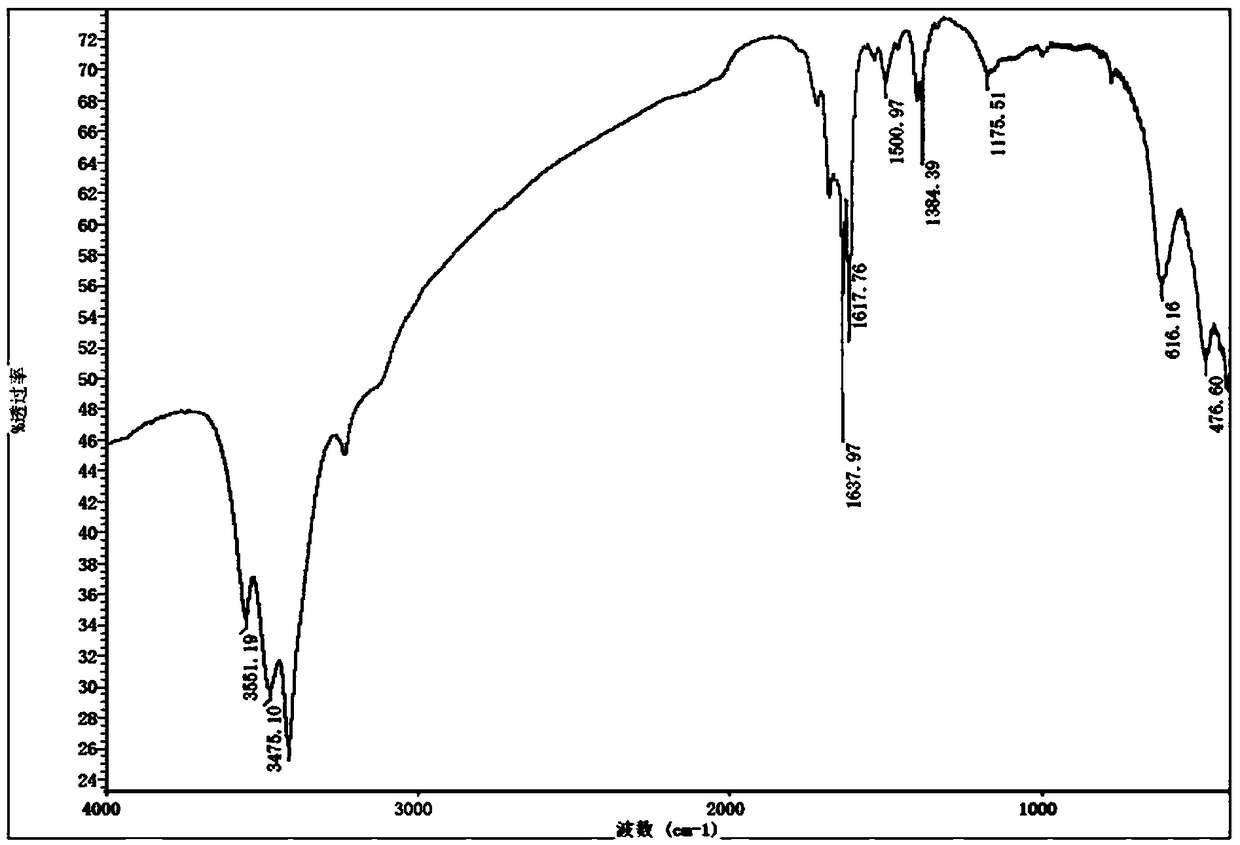

A technology of piperazine polyphosphate and polyphosphoric acid, which is applied in the direction of organic chemistry, can solve the problems of high energy consumption, corrosive equipment, and high equipment requirements, and achieve easy operation and industrialization, good flame retardant effect, and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

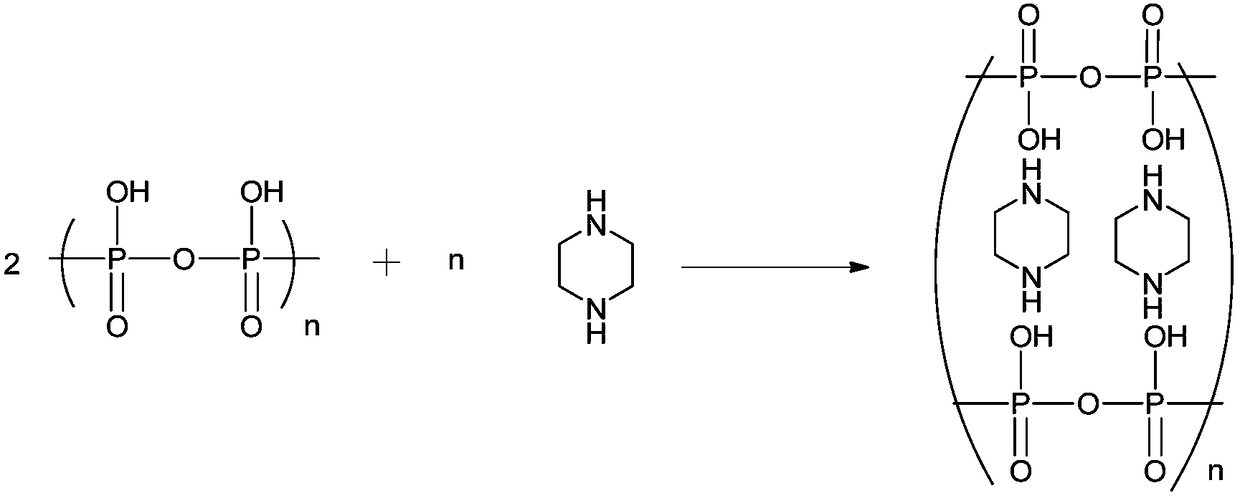

[0025] The present invention provides a kind of preparation method of piperazine polyphosphate, and the preparation method of piperazine polyphosphate comprises:

[0026] Salt forming step: Stir piperazine for 5 minutes to 30 minutes, then slowly add polyphosphoric acid preheated to 80°C to 100°C, keep the temperature at 45°C to 65°C, and stir for 0.5 hours to 3 hours to obtain the initial piperazine polyphosphate product.

[0027] Aging step: evacuate to a vacuum degree of 1000Pa-2000Pa, replace the inert gas several times and maintain the vacuum degree, continue to stir and heat to 150°C-200°C, and keep it for 1-4 hours to obtain piperazine polyphosphate.

[0028] In the preparation method of this piperazine polyphosphate, the reaction equation of polyphosphoric acid and piperazine is as follows:

[0029]

[0030] Where: n≥2.

[0031] The embodiment of the present invention also provides a kind of piperazine polyphosphate, the molecular structure of piperazine polyphosp...

Embodiment 1

[0035] Add 8.6kg of piperazine into the mixer, under stirring, slowly add 17.71kg of polyphosphoric acid (polymerization degree 2.1, preheated to 90°C) within 5 minutes, the material temperature is controlled at 60-65°C, keep the temperature after adding, continue React for 2 hours. Turn on the vacuum with a vacuum degree of 1000-2000 Pa. After nitrogen replacement for 5 times, keep the vacuum degree, continue stirring and heating to 150-160°C, and then continue aging and devolatilization for 4 hours to obtain piperazine polyphosphate. Cooling, crushing, packaging.

Embodiment 2

[0037] Add 8.6kg of piperazine into the mixer, under stirring, slowly add 18.57kg of polyphosphoric acid (polymerization degree 1.4, preheated to 80°C) within 5 minutes, control the material temperature at 45-50°C, keep the temperature after adding, continue React for 0.5 hours. Turn on the vacuum with a vacuum degree of 1000-2000 Pa. After nitrogen replacement for 5 times, keep the vacuum degree, continue to stir and heat to 190-200°C, then continue aging and devolatilization for 4 hours to obtain piperazine polyphosphate. Cooling, crushing, packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com