Wall space repairing material and preparation method thereof

A repairing material and technology to be repaired, applied in the field of building materials, can solve the problems of lack of repairing materials to protect loess cave dwelling sites, and achieve the effects of improving void structure and easy erosion, improving freeze-thaw resistance, and strengthening cementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

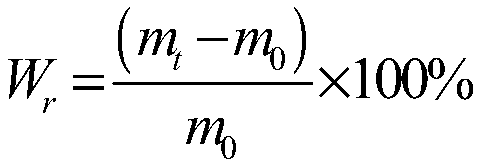

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a kind of preparation method of wall repair material, comprises the following steps:

[0033] Mix glutinous rice pulp, silica fume, quicklime, hemihydrate gypsum, fiber material, the original soil of the cave dwelling to be repaired, and a water reducer to form a wall repair material.

[0034] Specifically: first, prepare glutinous rice slurry: pregelatinize glutinous rice flour and water, the time of pregelatinization is 60-90 minutes, and the temperature of pregelatinization is 80-90°C. Using the temperature and time of the above pregelatinization can ensure that the glutinous rice and water are fully gelatinized to obtain glutinous rice pulp, and avoid the structure of the glutinous rice pulp being damaged due to insufficient gelatinization or excessive gelatinization of the glutinous rice. And in the process of pregelatinization, it is necessary to keep stirring and keep the water level constant, so as to avoid the agglomeration of ...

Embodiment 1

[0042] This embodiment provides a wall repair material, which includes 360 parts of glutinous rice pulp, 205 parts of hemihydrate gypsum, 133 parts of quicklime, 150 parts of wollastonite powder, 13 parts of water reducing agent, and the original soil of the cave dwelling to be repaired. 555 parts and 4 parts of fiber material. Among them, the original soil of the cave to be repaired is loess with a moisture content of 10%, the fiber material is hemp knife fiber, the length is 2 cm, and the mass percentage concentration of glutinous rice pulp is 2.5%.

[0043] The present embodiment provides a kind of preparation method of wall repair material:

[0044] First, glutinous rice flour and water are mixed according to the mass ratio of 39:1 for pre-gelatinization, the pre-gelatinization time is 20 minutes, and the pre-gelatinization temperature is 90°C. Then the obtained slurry is cooled so that the temperature of the glutinous rice slurry is 20°C.

[0045] Then the first mixture...

Embodiment 2-6

[0048] The composition of the wall repairing material provided in Example 2-6 is basically the same as that of the wall repairing material provided in Example 1, the difference being that the ratio of each raw material is different, the preparation method and implementation of the wall repairing material provided in Example 2-6 The preparation methods of the wall repair materials provided in Example 1 are basically the same, the difference lies in the change of specific operating conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com