Micromechanical electrostatic driven linear comb structure

An electrostatic drive and comb-tooth structure technology, which is applied in the direction of microelectronic microstructure devices, microstructure technology, microstructure devices, etc., can solve the problems of reducing the driving voltage of the structure, achieve a large driving stroke, reduce weight, and increase the cavity volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0022] The invention provides a micro-mechanical electrostatically driven linear comb structure, which achieves a larger driving stroke under the same vacuum environment and driving voltage as the traditional technology, without increasing the difficulty of the process.

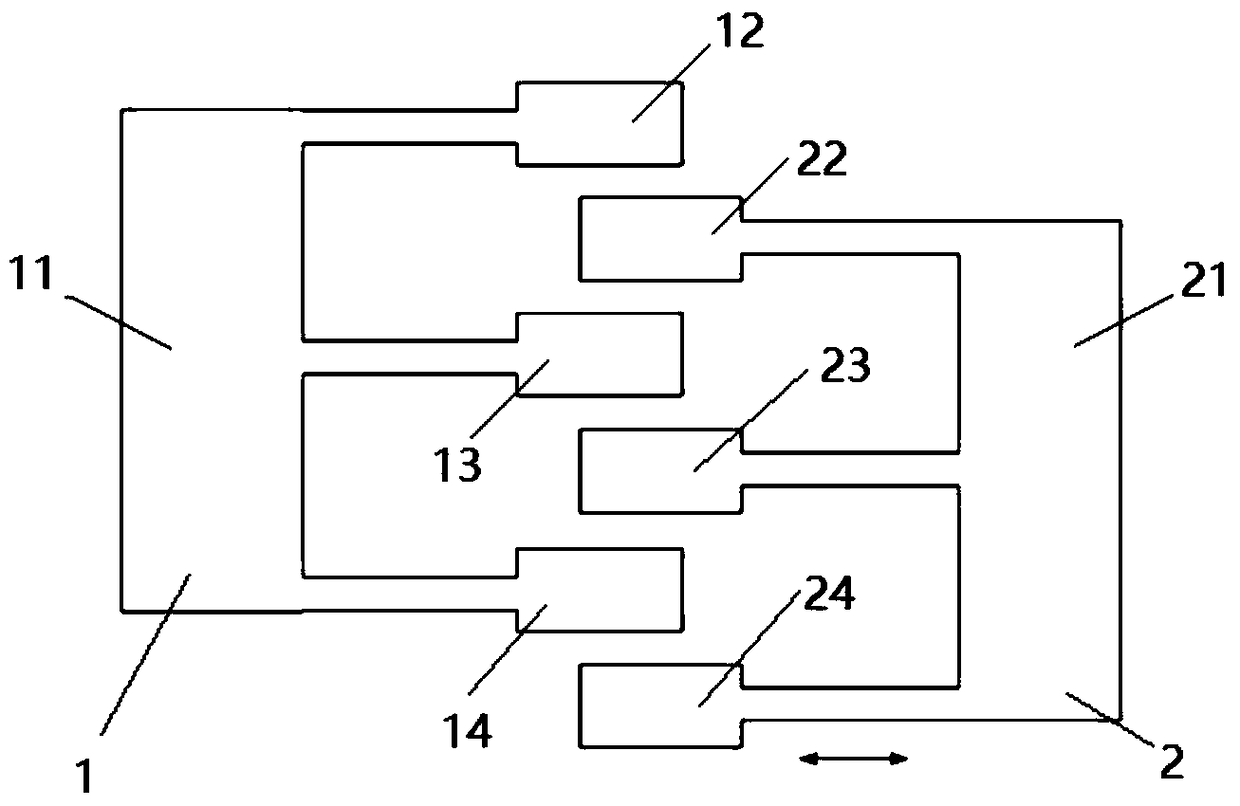

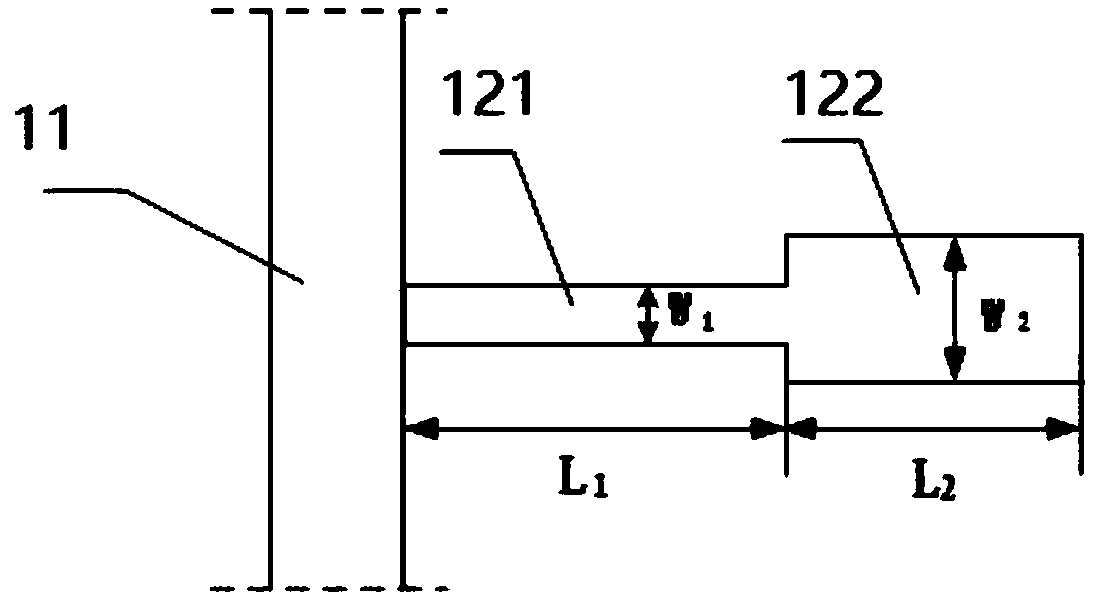

[0023] Such as figure 1 Shown is a schematic diagram of a linear comb group. It can be seen from the figure that a micro-mechanical electrostatically driven linear comb structure includes n groups of the same linear comb group; n groups of linear comb groups are evenly distributed on the outside On the horizontal side wall of the device; each group of linear combs includes static combs (1) and dynamic combs (2); the static combs 1 and the dynamic combs 2 are E-shaped structures that are interlaced; the static combs A voltage is applied between 1 and the moving comb 2, under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com