a kind of ag 2 oQuantum dot hybrid znin 2 the s 4 Preparation method of nanosheet p-n type composite photocatalyst

A nanosheet, composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, special compound water treatment, etc., can solve problems affecting the popularization and application of photocatalytic technology, low photoelectric conversion efficiency, incomplete utilization of light sources, etc , to achieve the effect of being conducive to large-scale production, short preparation cycle, and promoting effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

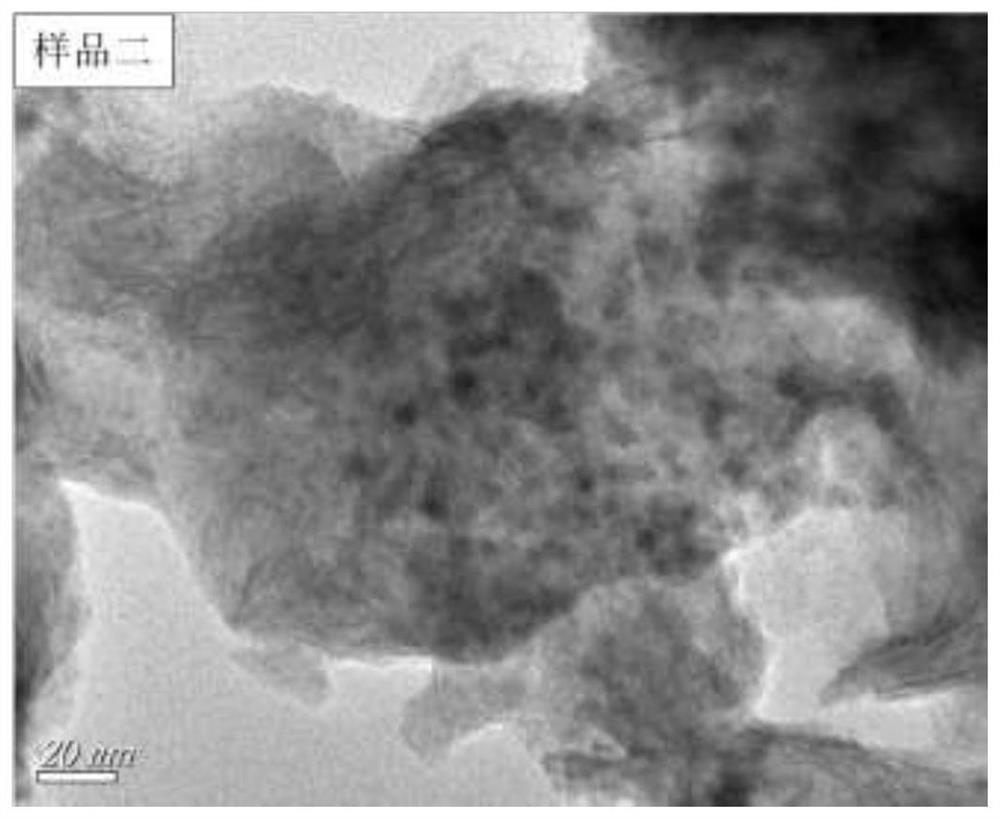

[0022] (1) Weigh 0.099g of ZnIn 2 S 4 Nanosheets were added to 10mL of methanol, stirred for 10min, and then ultrasonicated for 10min, repeated three times to obtain uniformly dispersed ZnIn 2 S 4 nanosheet suspension;

[0023] (2) Measure 0.916mL of AgNO with a concentration of 0.8g / L 3 Methanol solution is added to the uniformly dispersed ZnIn prepared in step (1) 2 S 4 The nanosheet suspension was stirred for 30 min in the dark, and then 21.6 μL of NaOH aqueous solution with a concentration of 0.4 mol / L was added dropwise, in which AgNO 3 The molar ratio with NaOH was 1:2, and continued to stir for 60 min. After the reaction, the obtained product was washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain Ag 2 O quantum dot hybrid ZnIn 2 S 4 Nanosheet p-n type composite photocatalyst, in which Ag 2The mass fraction of O quantum dots is 0.5%.

[0024] (3) The sample was irradiated under visible light for 100 minutes, and the de...

example 2

[0026] (1) Weigh 0.15g of ZnIn 2 S 4 Nanosheets were added to 20mL of methanol, stirred for 15min, and then ultrasonicated for 10min, repeated three times to obtain uniformly dispersed ZnIn 2 S 4 nanosheet suspension;

[0027] (2) Measure 1.83mL of AgNO with a concentration of 1.2g / L 3 Methanol solution is added to the uniformly dispersed ZnIn prepared in step (1) 2 S 4 The nanosheet suspension was stirred for 40 min in the dark, and then 32.4 μL of NaOH aqueous solution with a concentration of 0.8 mol / L was added dropwise, in which AgNO 3 The molar ratio with NaOH was 1:2, and continued to stir for 80 min. After the reaction was over, the obtained product was washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain Ag 2 O quantum dot hybrid ZnIn 2 S 4 Nanosheet p-n type composite photocatalyst, in which Ag 2 The mass fraction of O quantum dots is 1%.

[0028] (3) The sample was irradiated under visible light for 100 min, and the ...

example 3

[0031] (1) Weigh 0.2g of ZnIn 2 S 4 Nanosheets were added to 30mL of methanol, stirred for 20min, and then ultrasonicated for 15min, repeated three times to obtain uniformly dispersed ZnIn 2 S 4 nanosheet suspension;

[0032] (2) Measure 4.54mL of AgNO with a concentration of 2g / L 3 Methanol solution is added to the uniformly dispersed ZnIn prepared in step (1) 2 S 4 The nanosheet suspension was stirred in the dark for 50 min, and then 133.8 μL of NaOH aqueous solution with a concentration of 1.2 mol / L was added dropwise, in which AgNO 3 The molar ratio with NaOH is 1:3, continue to stir for 100min, after the reaction is over, wash the obtained product several times with deionized water and absolute ethanol, and dry it in vacuum to obtain Ag 2 O quantum dot hybrid ZnIn 2 S 4 Nanosheet p-n type composite photocatalyst, in which Ag 2 The mass fraction of O quantum dots is 3%.

[0033] (3) The sample was irradiated under visible light for 100 min, and the degradation ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com