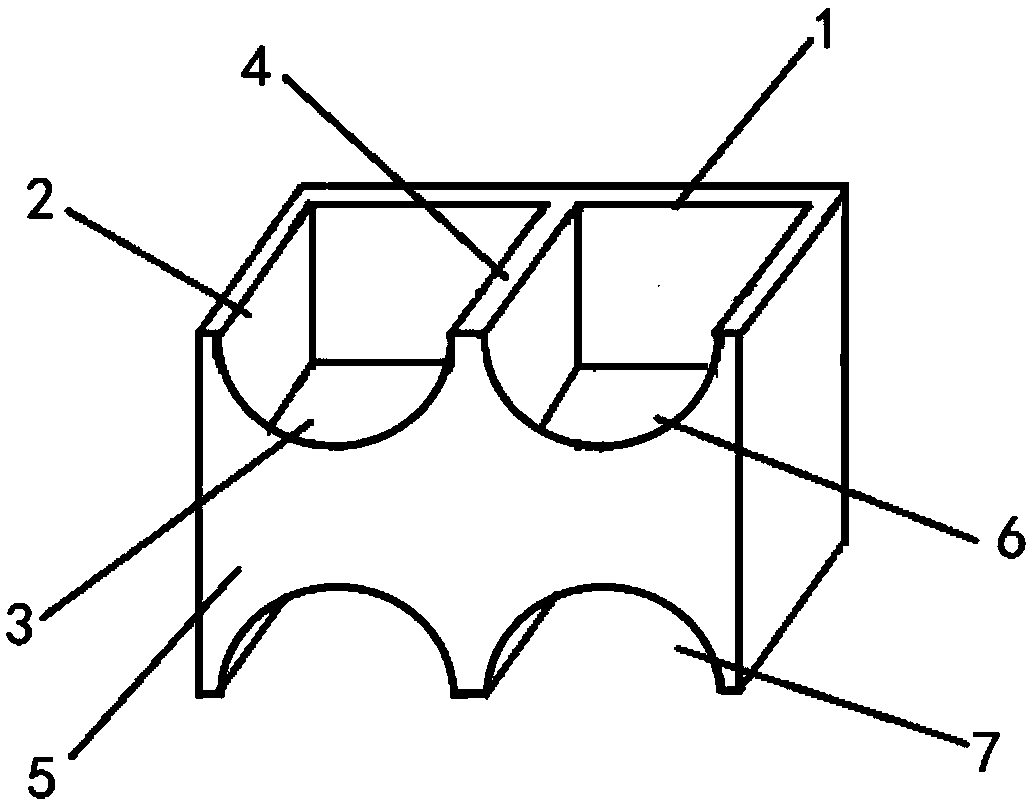

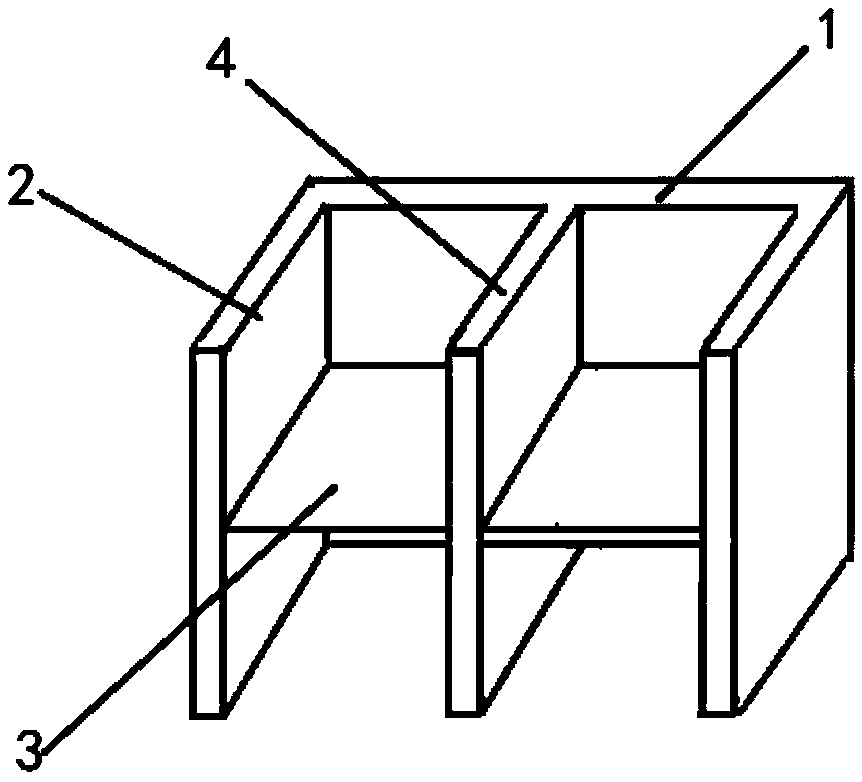

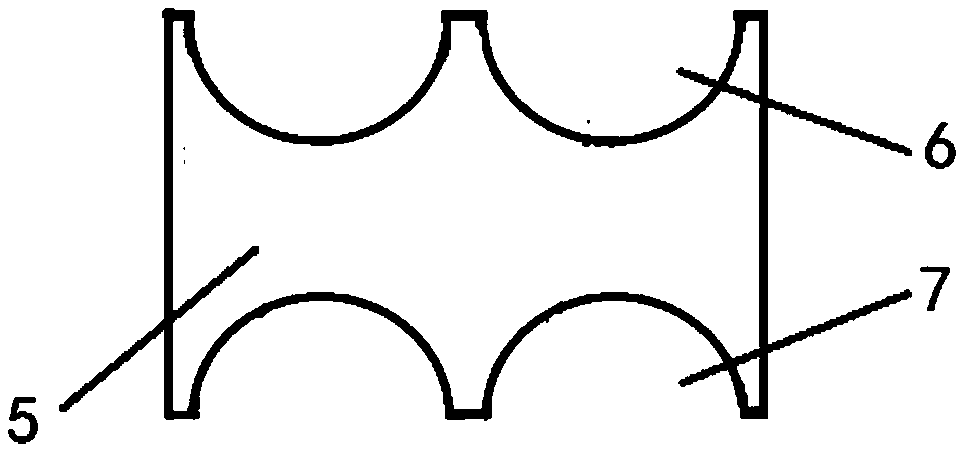

Water storage component for vertical greening

A technology of vertical greening and components, applied in drinking water installations, general water supply saving, application, etc., can solve the problems of increased cost of vertical greening walls, poor plant growth, expensive green walls, etc., to reduce wet work and construction Garbage, easy plant growth, and convenient post-maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The rear wall, front wall, side wall, transverse diaphragm and longitudinal diaphragm of the water storage and retention member are made by the following method: raw materials are taken according to mass percentage: 30% ordinary Portland cement, 20% low-alkali sulphoaluminate cement, 10% high belite cement, 10% fly ash, 10% slag, 2% silica fume, 2% ferrous sulfate, 8% plant ash and 8% sepiolite, mix, add 40% water of raw material quality, stir Evenly, then add 35% hydrogen peroxide with a concentration of 3% of the raw material mass, stir for 12 seconds, pour into the mold for foaming and molding.

Embodiment 2

[0019] The rear wall, front wall, side wall, transverse partition and longitudinal partition of the water storage and retention components are made by the following method: raw materials are taken according to mass percentage: 20% ordinary Portland cement, 30% low-alkali sulfoaluminate cement , 5% high Belite cement, 15% fly ash, 2% slag, 3% silica fume, 2% ferrous sulfate, 8% plant ash and 15% sepiolite, mix, add 30% water of raw material quality, Stir evenly, then add 35% hydrogen peroxide with a concentration of 2% of the raw material mass, stir for 10 seconds, and pour into a mold for foaming.

Embodiment 3

[0021] The rear wall, front wall, side wall, transverse diaphragm and longitudinal diaphragm of the water storage and retention member are made by the following method: raw materials are taken according to mass percentage: 40% ordinary Portland cement, 10% low-alkali sulphoaluminate cement, 20% high belite cement, 5% fly ash, 15% slag, 1% silica fume, 0.5% ferrous sulfate, 3.5% plant ash and 5% sepiolite, mix, add 45% water of raw material quality, stir Evenly, then add 27.5% hydrogen peroxide with a concentration of 4.8% of the raw material mass, stir for 15 seconds, and pour into a mold for foaming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com